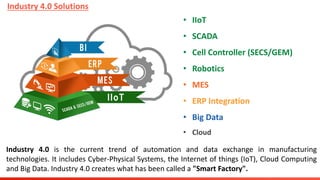

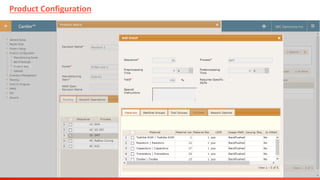

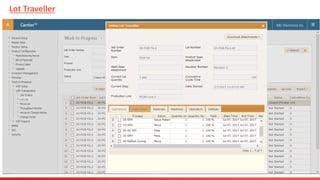

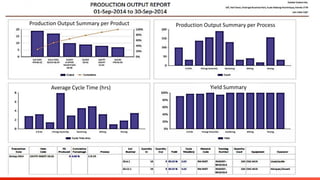

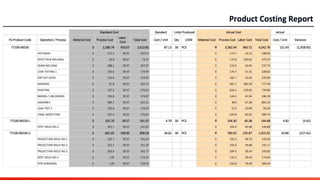

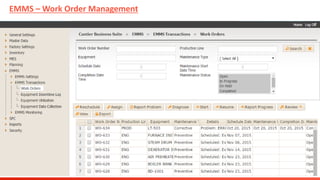

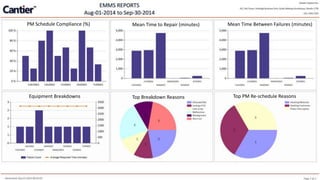

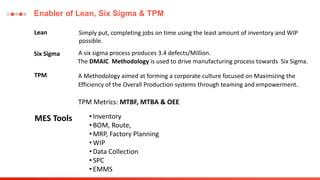

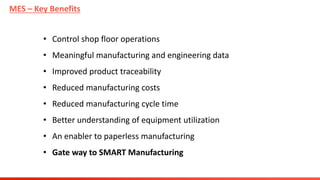

The document discusses Industry 4.0 and how it enables smart manufacturing through technologies like cyber-physical systems, the Internet of Things, cloud computing, and big data. It states that manufacturing execution systems (MES) play a fundamental role as the base for smart production solutions by providing real-time operational data and enabling timely decision-making. The document promotes Cantier MES software as a configurable and scalable platform that can serve as a gateway to achieving smart manufacturing goals.