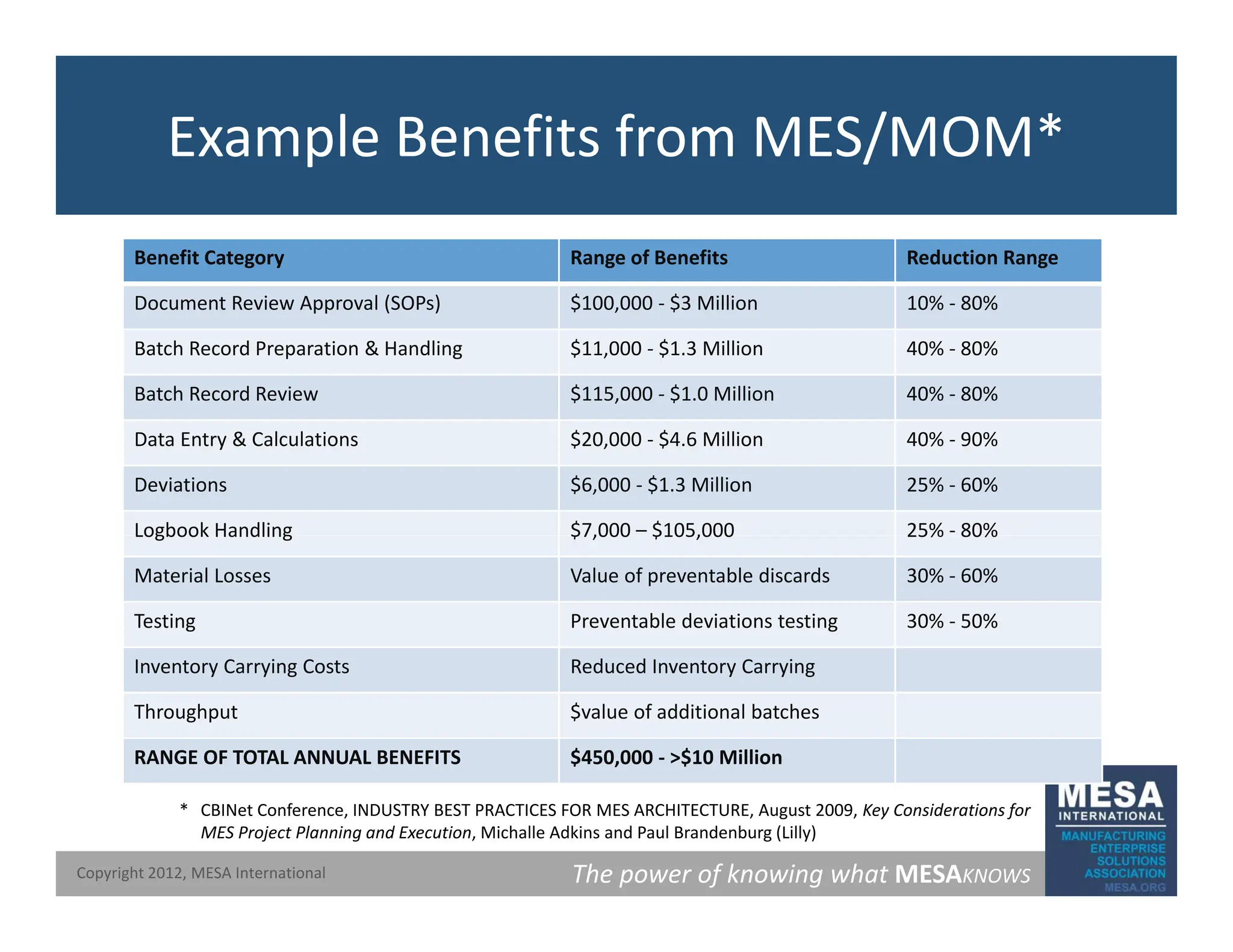

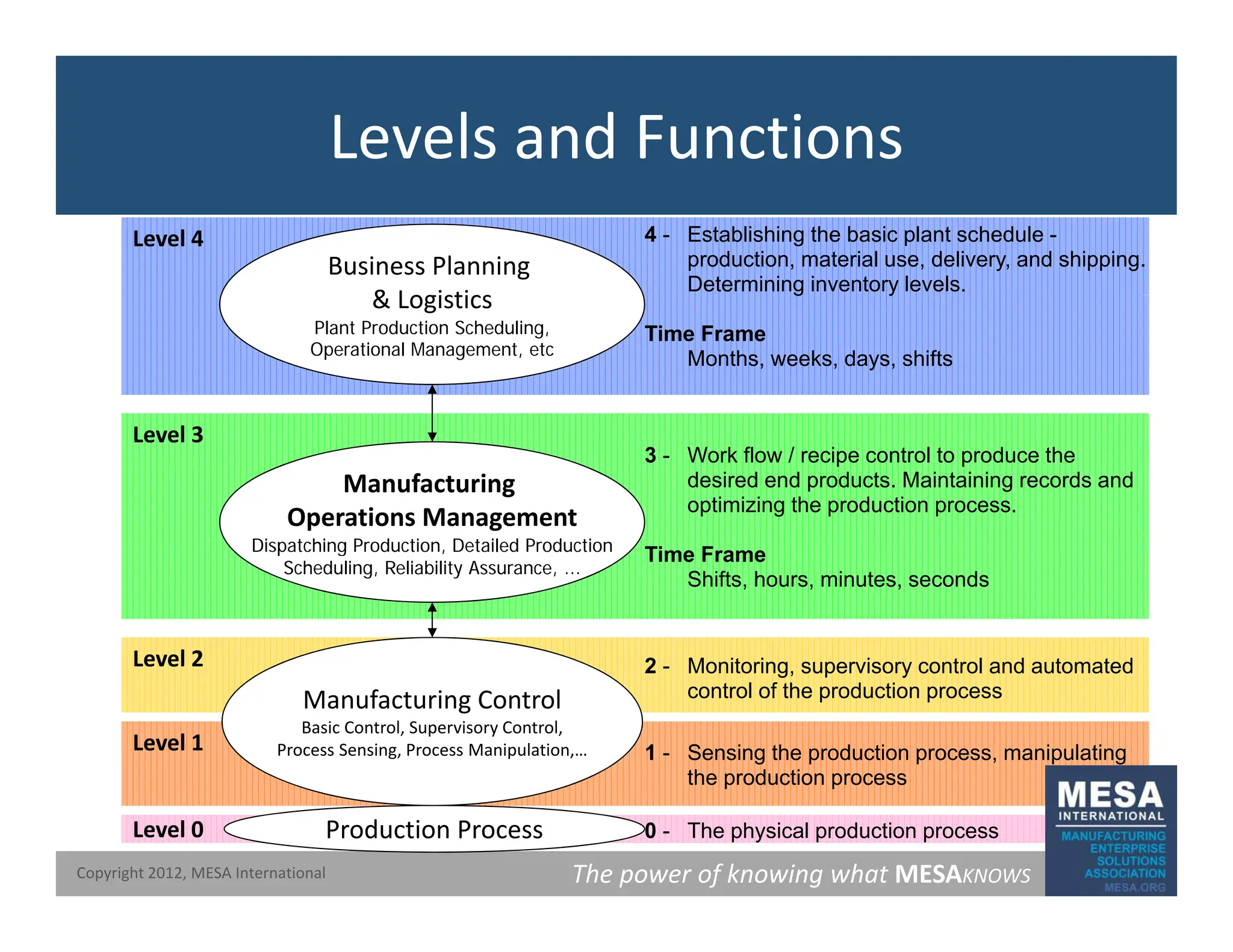

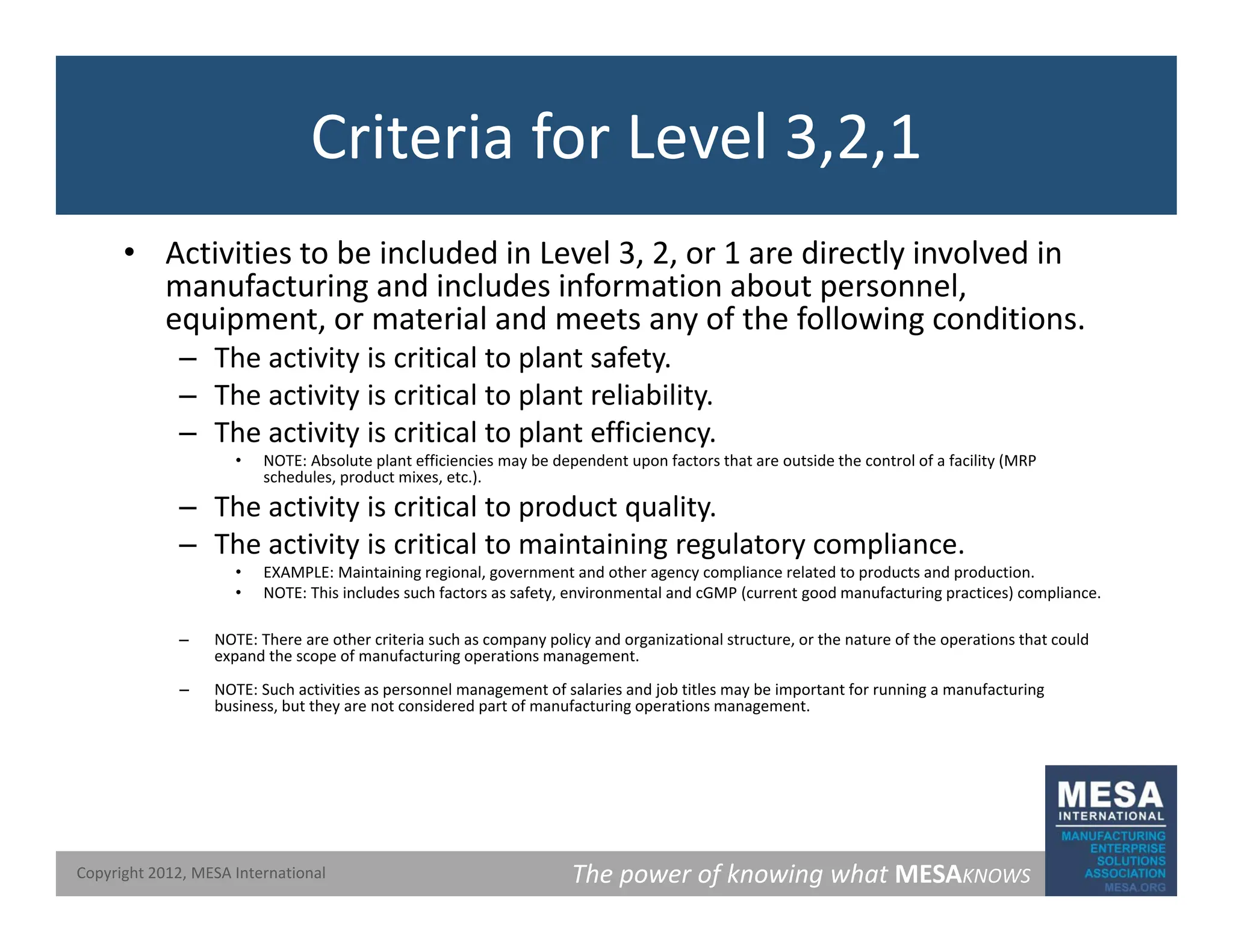

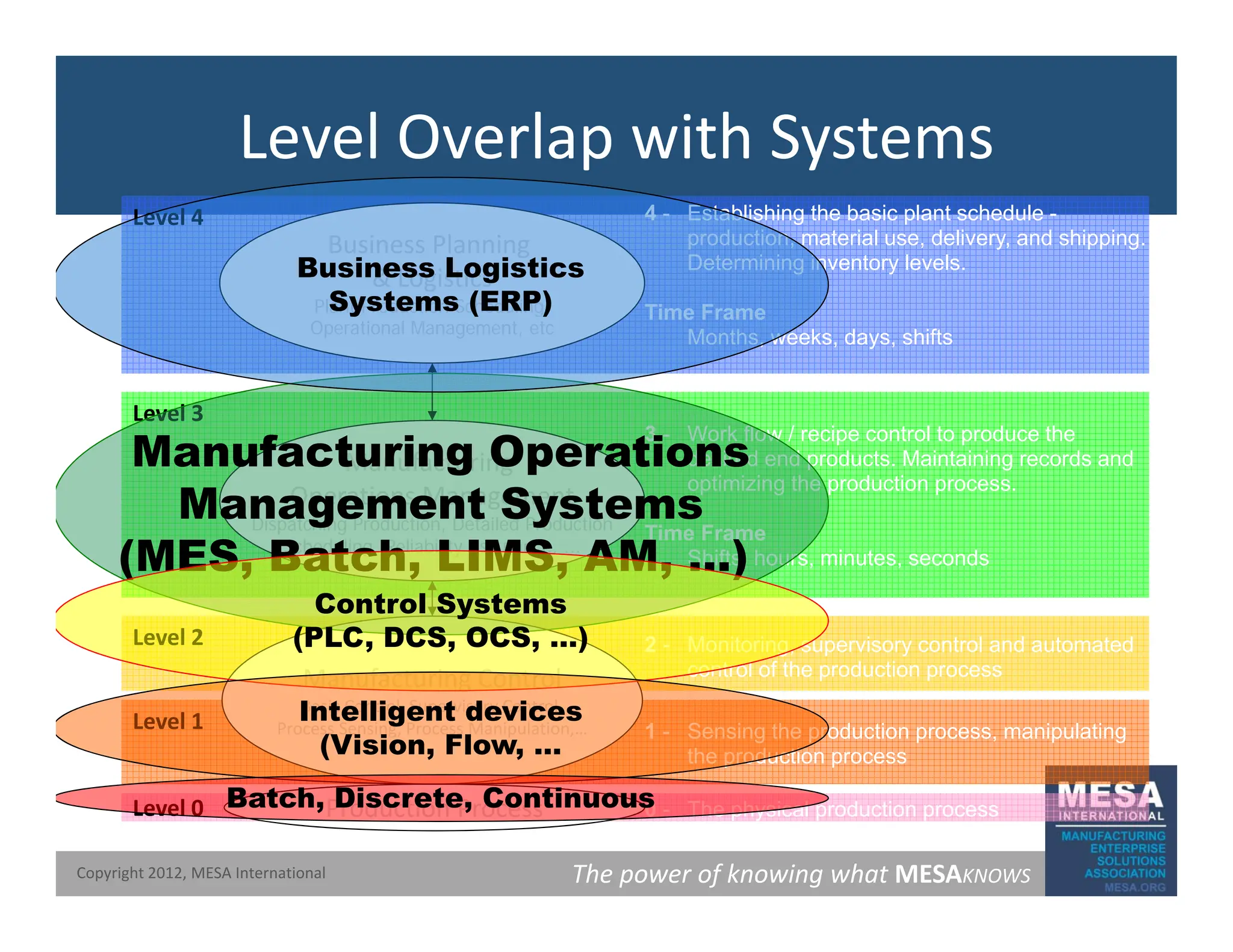

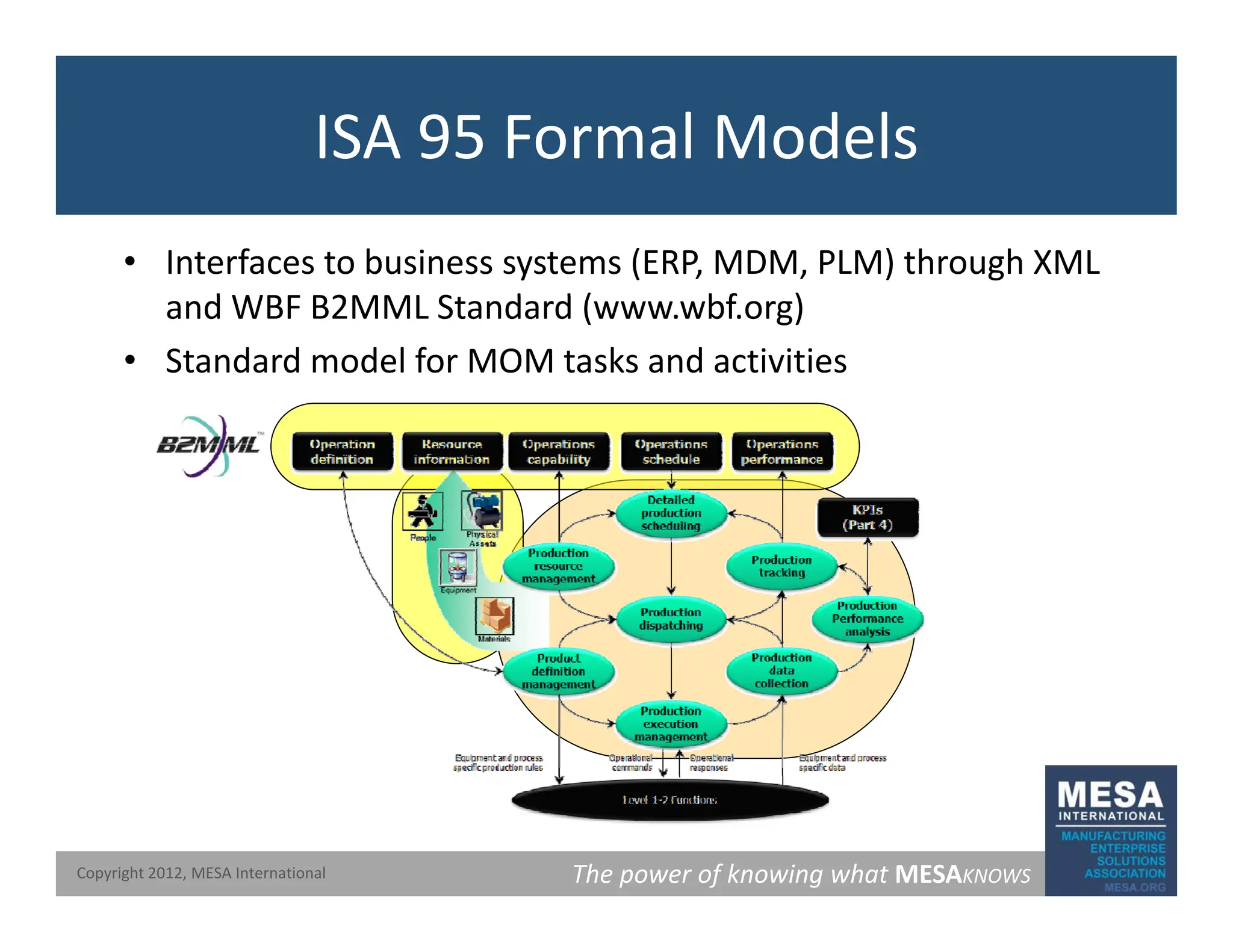

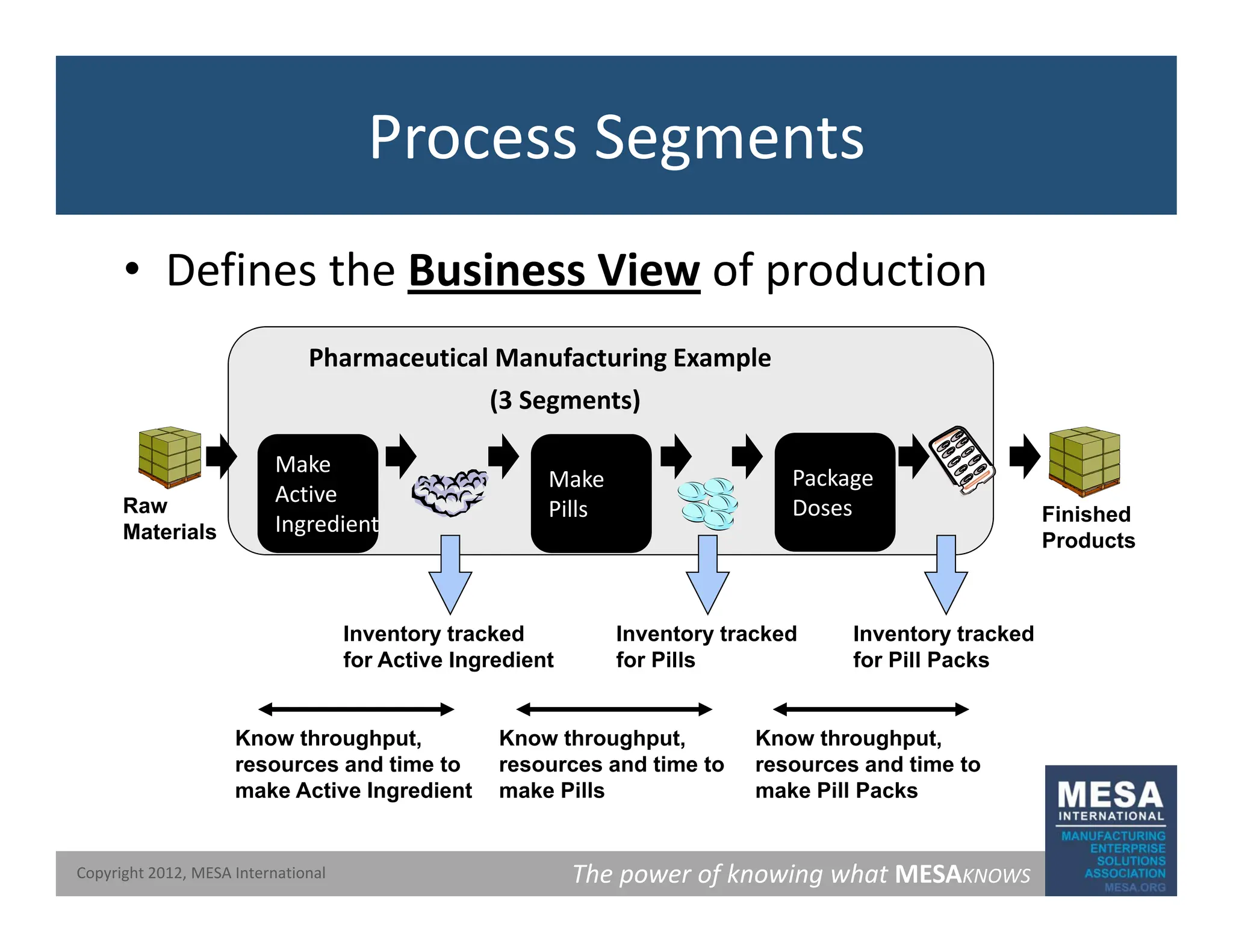

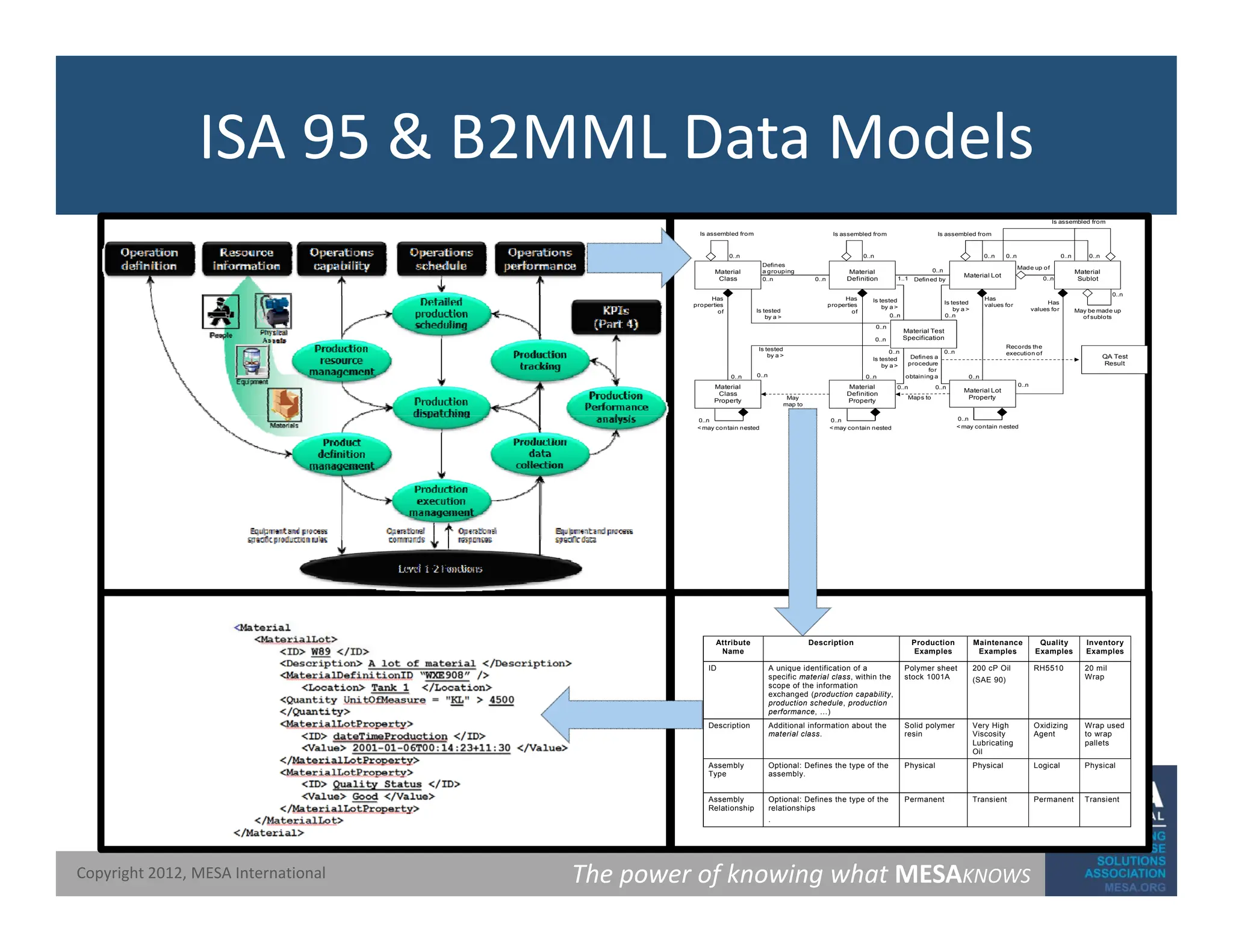

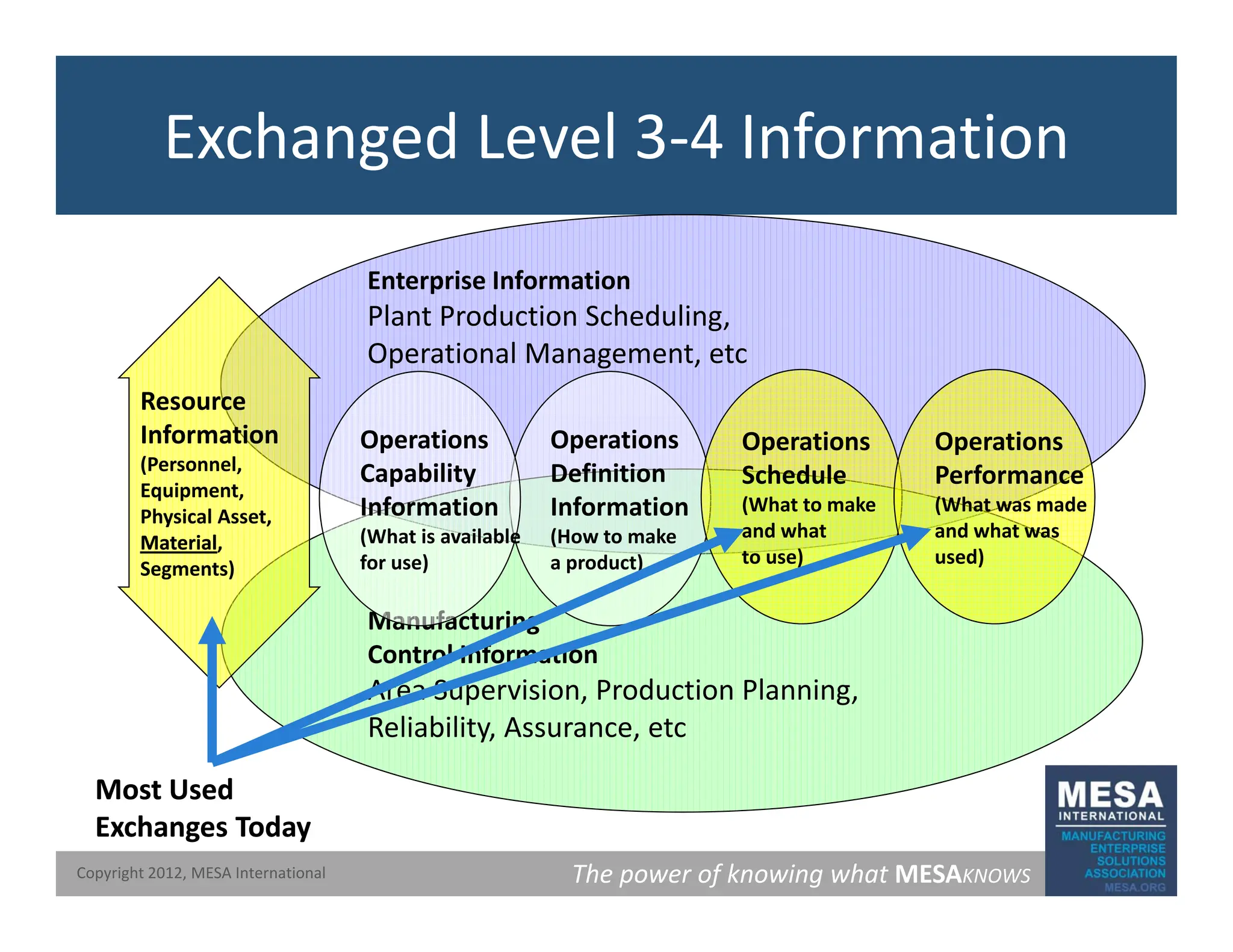

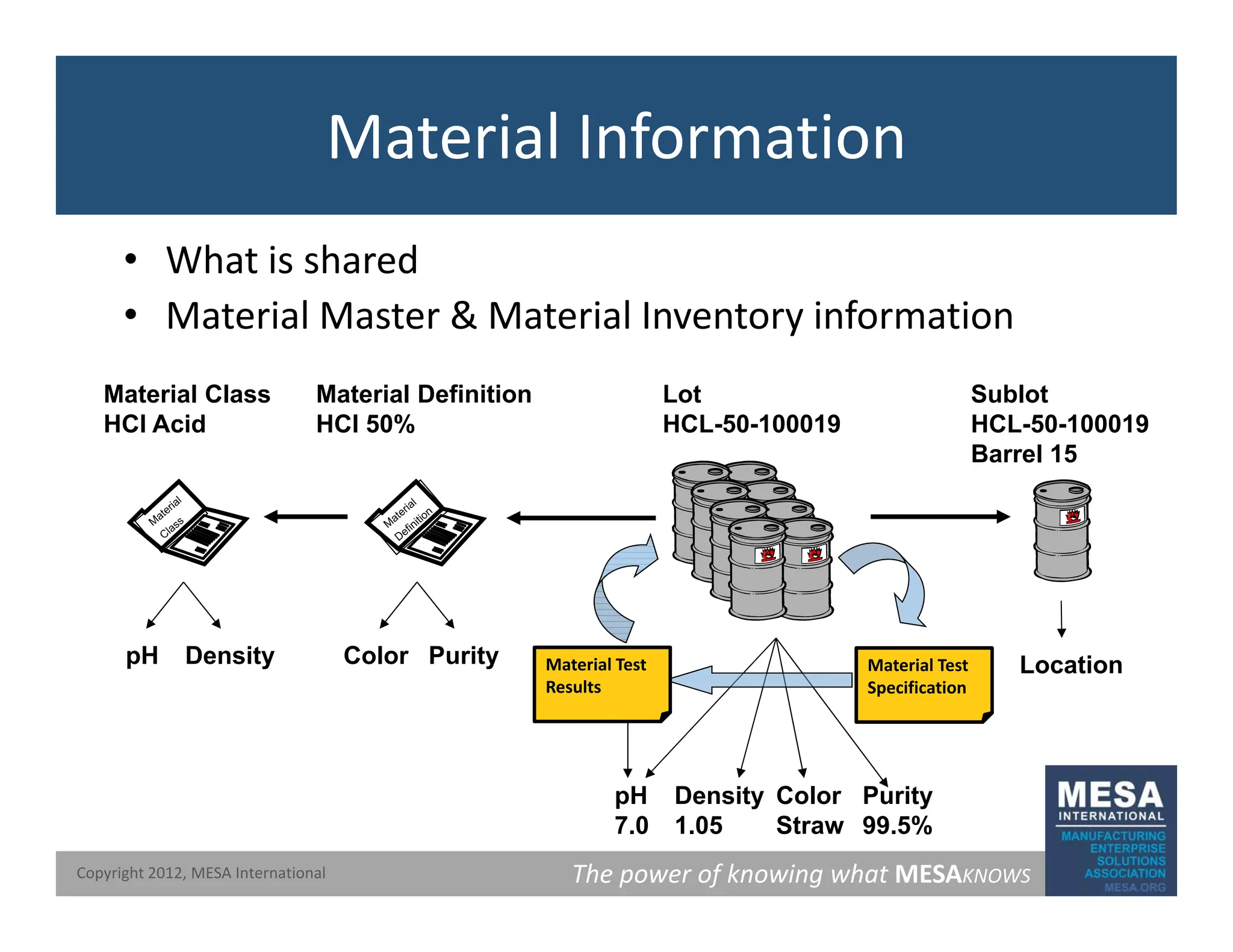

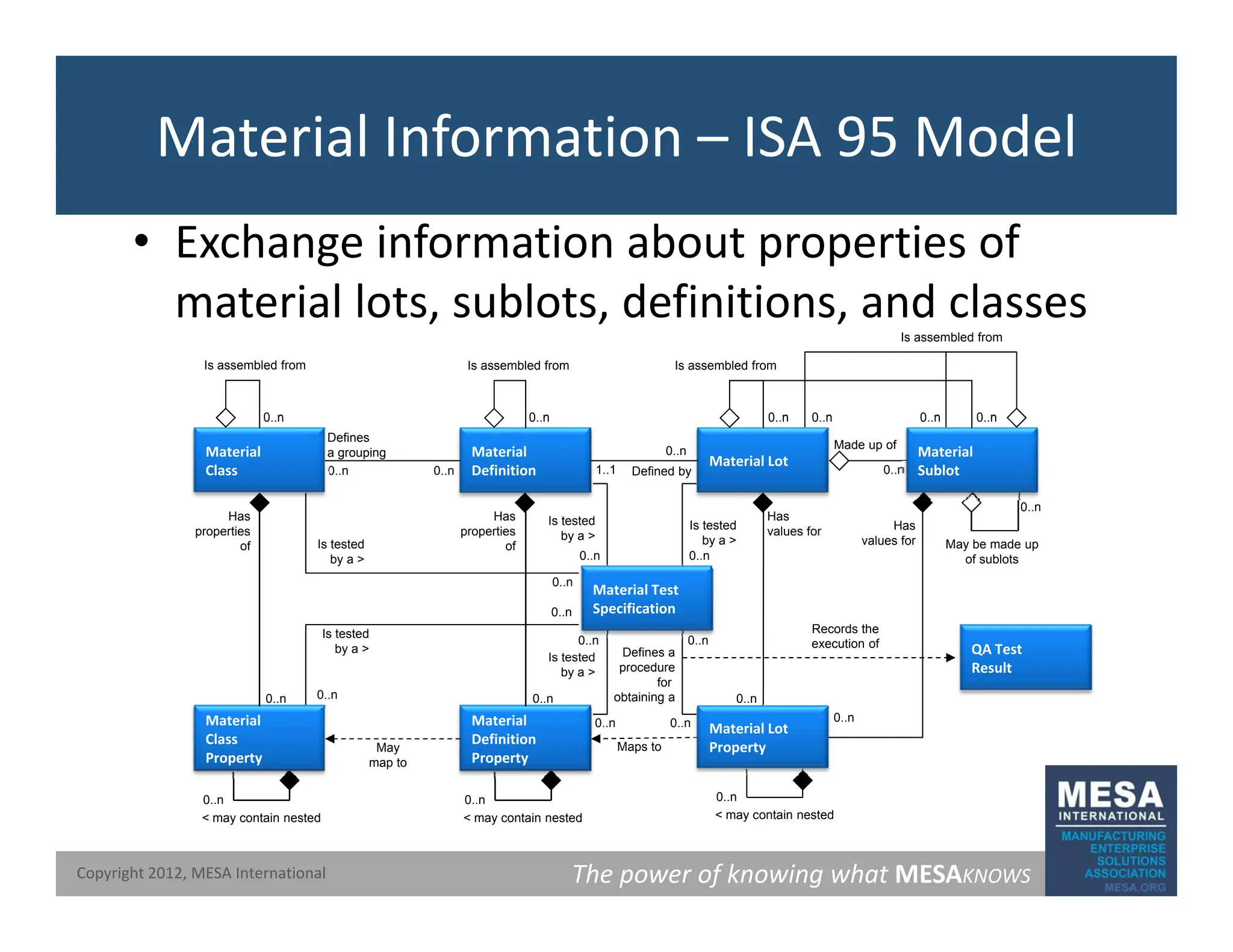

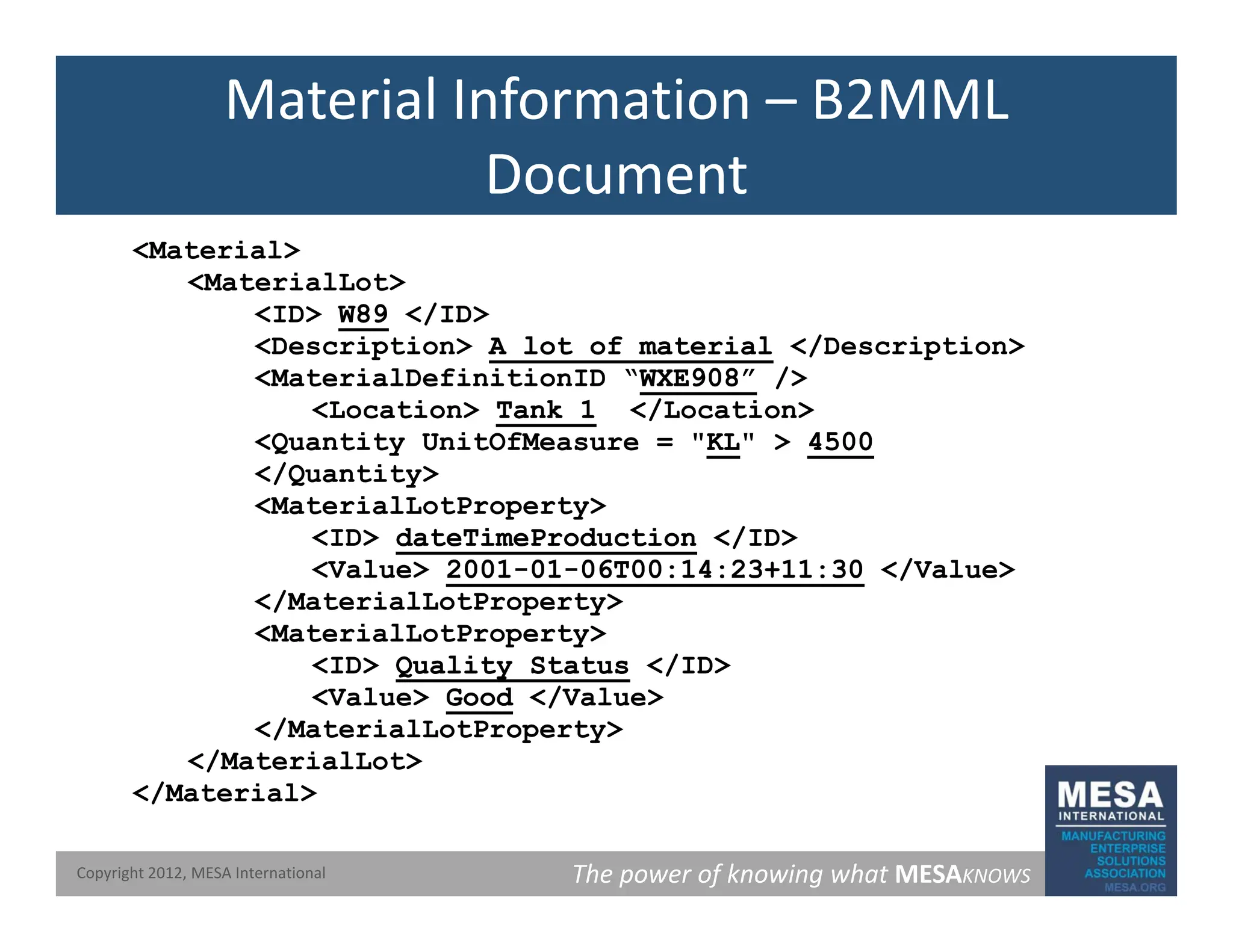

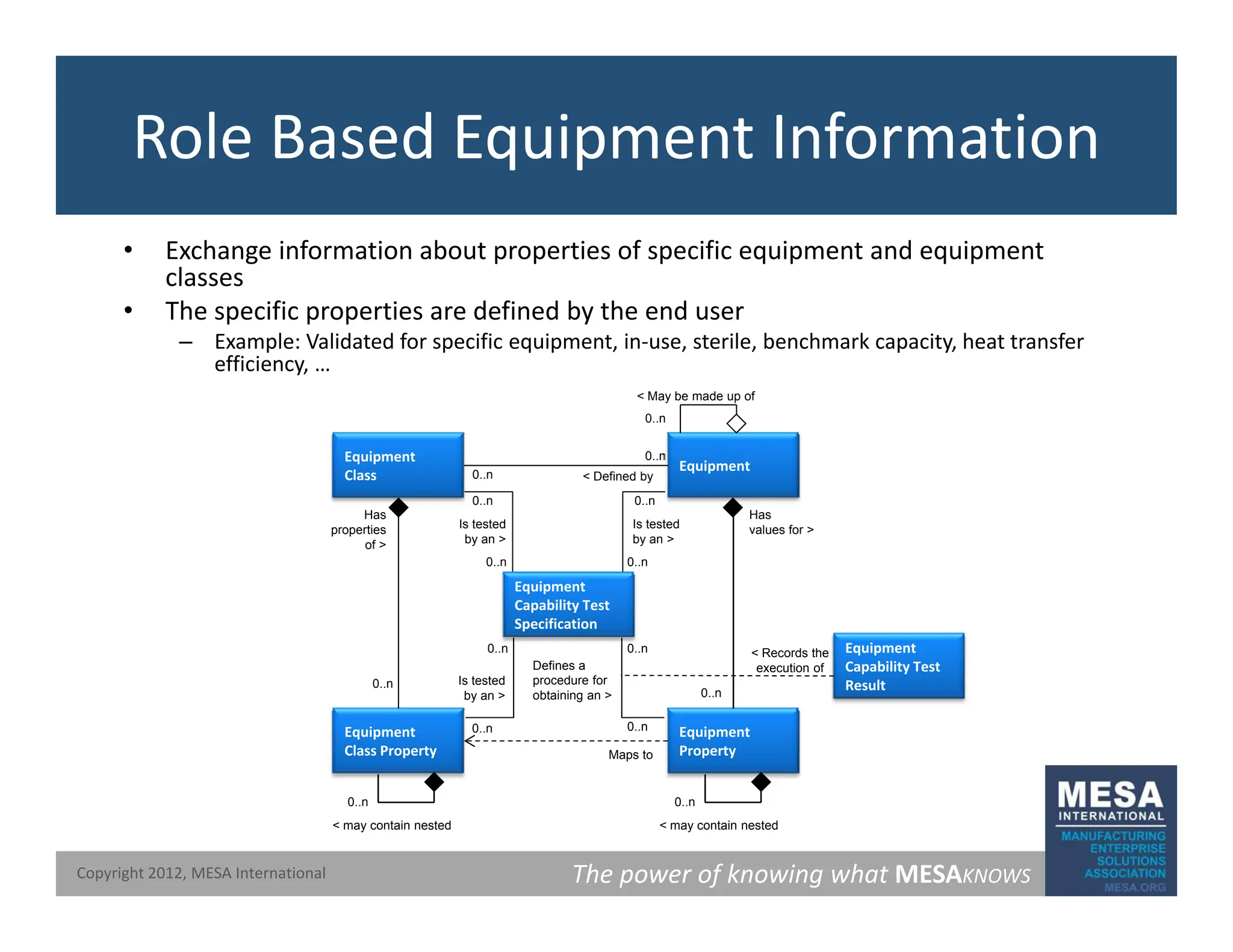

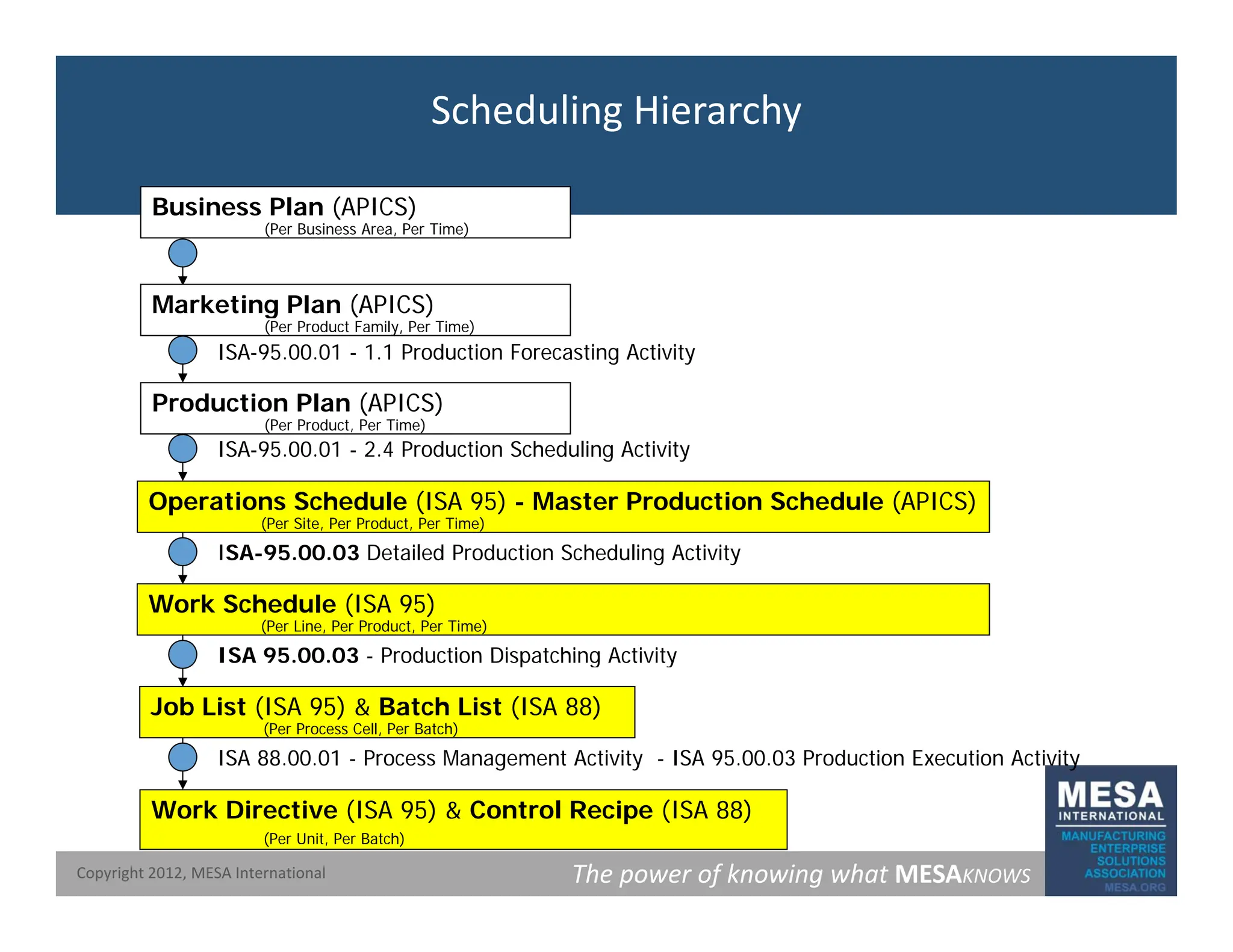

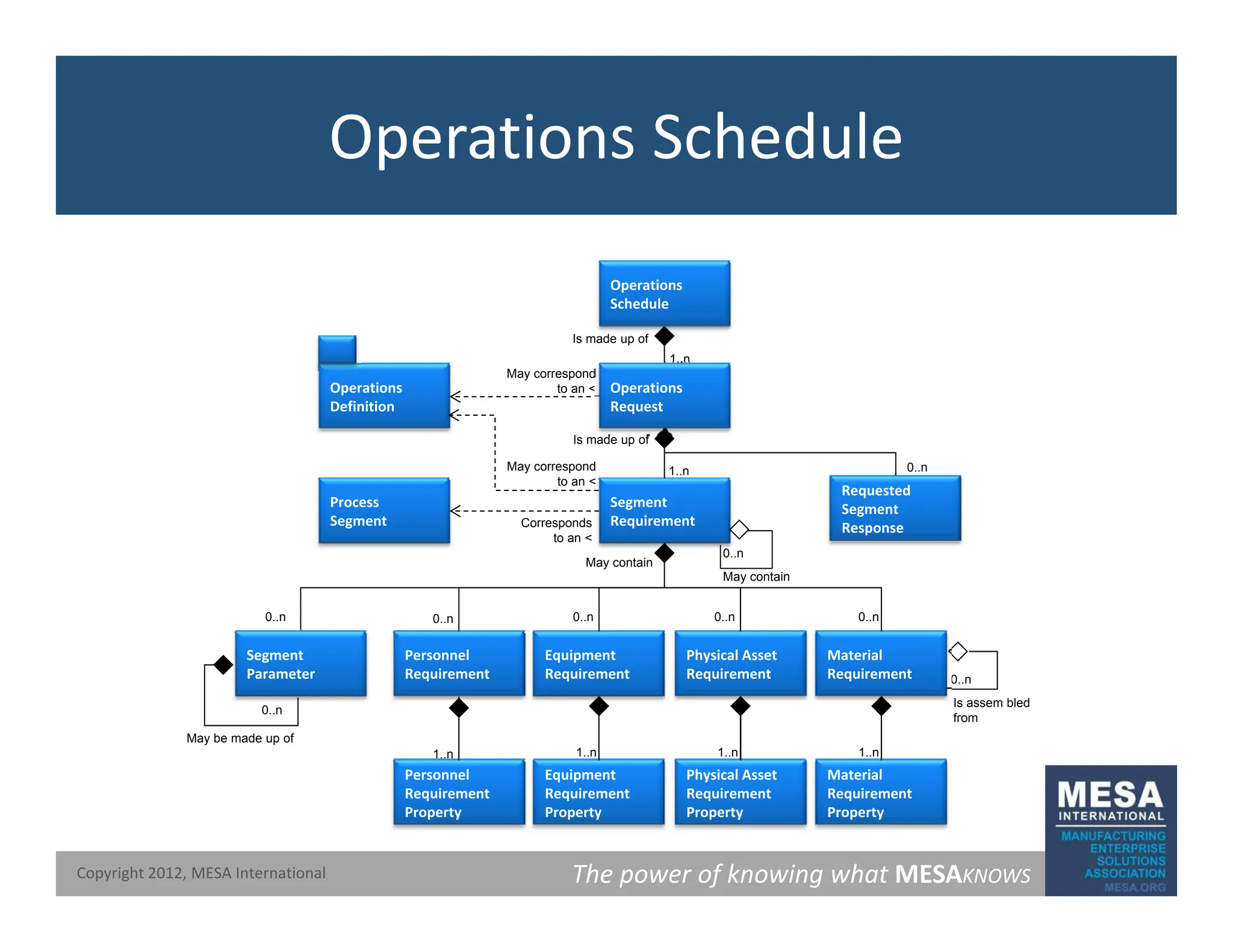

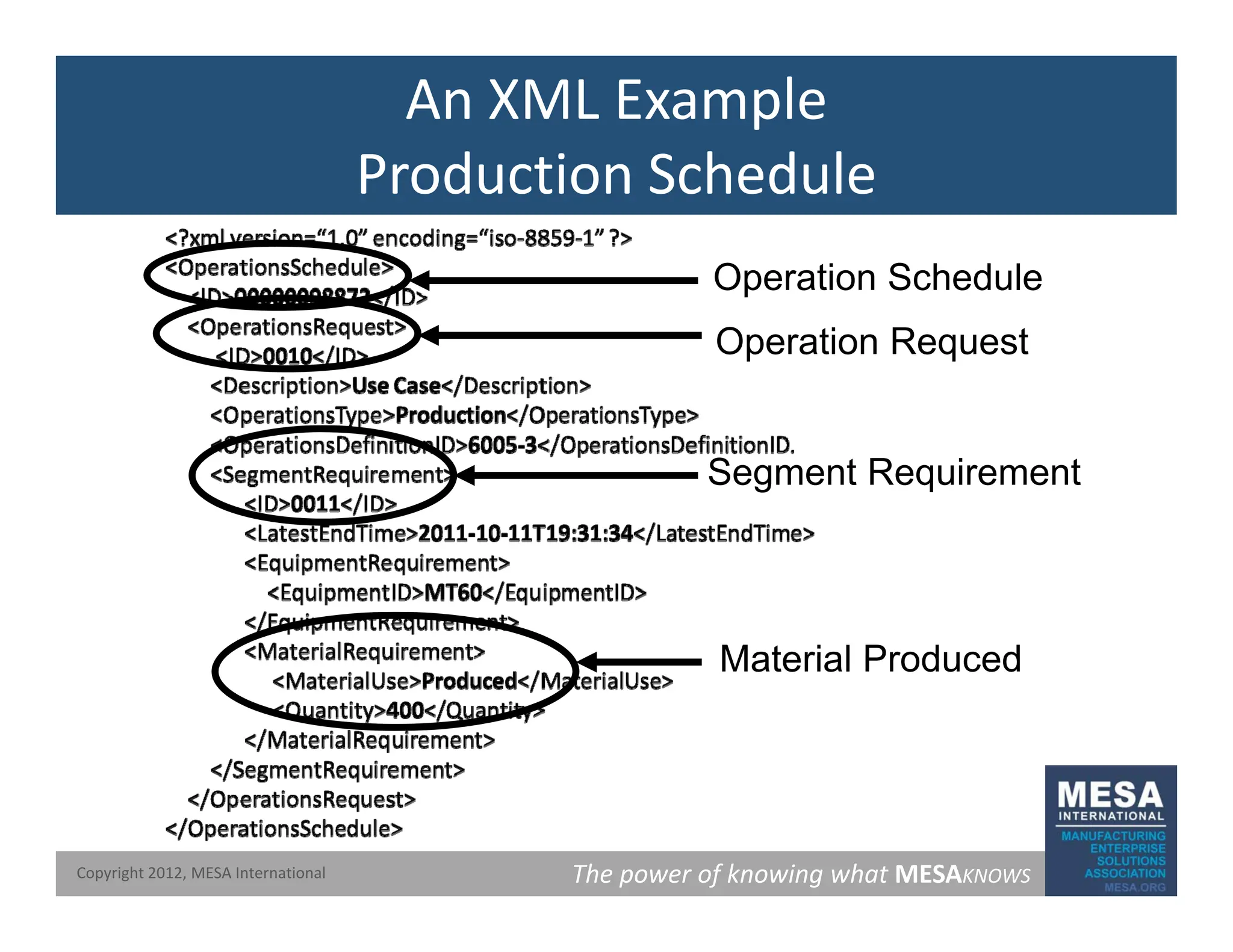

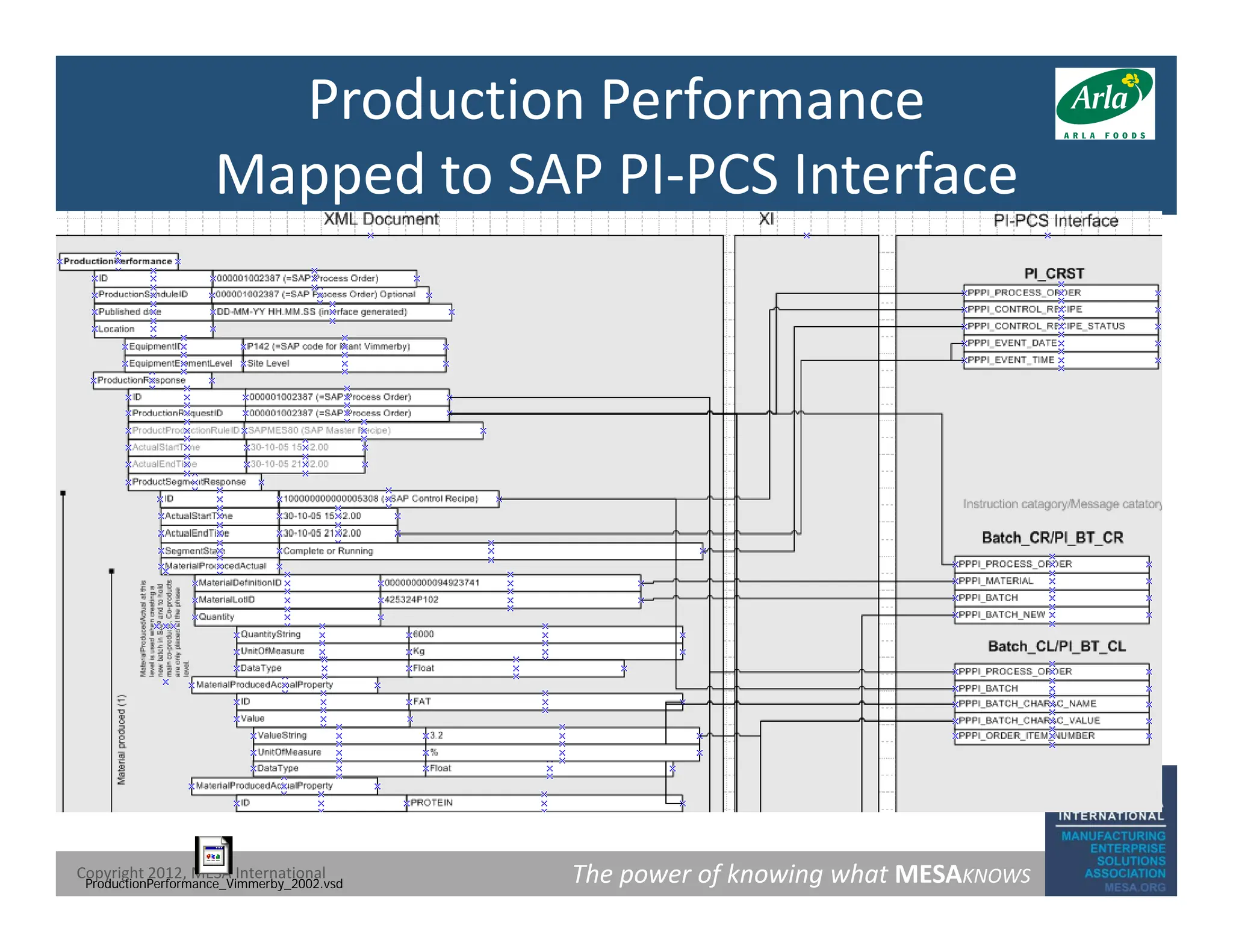

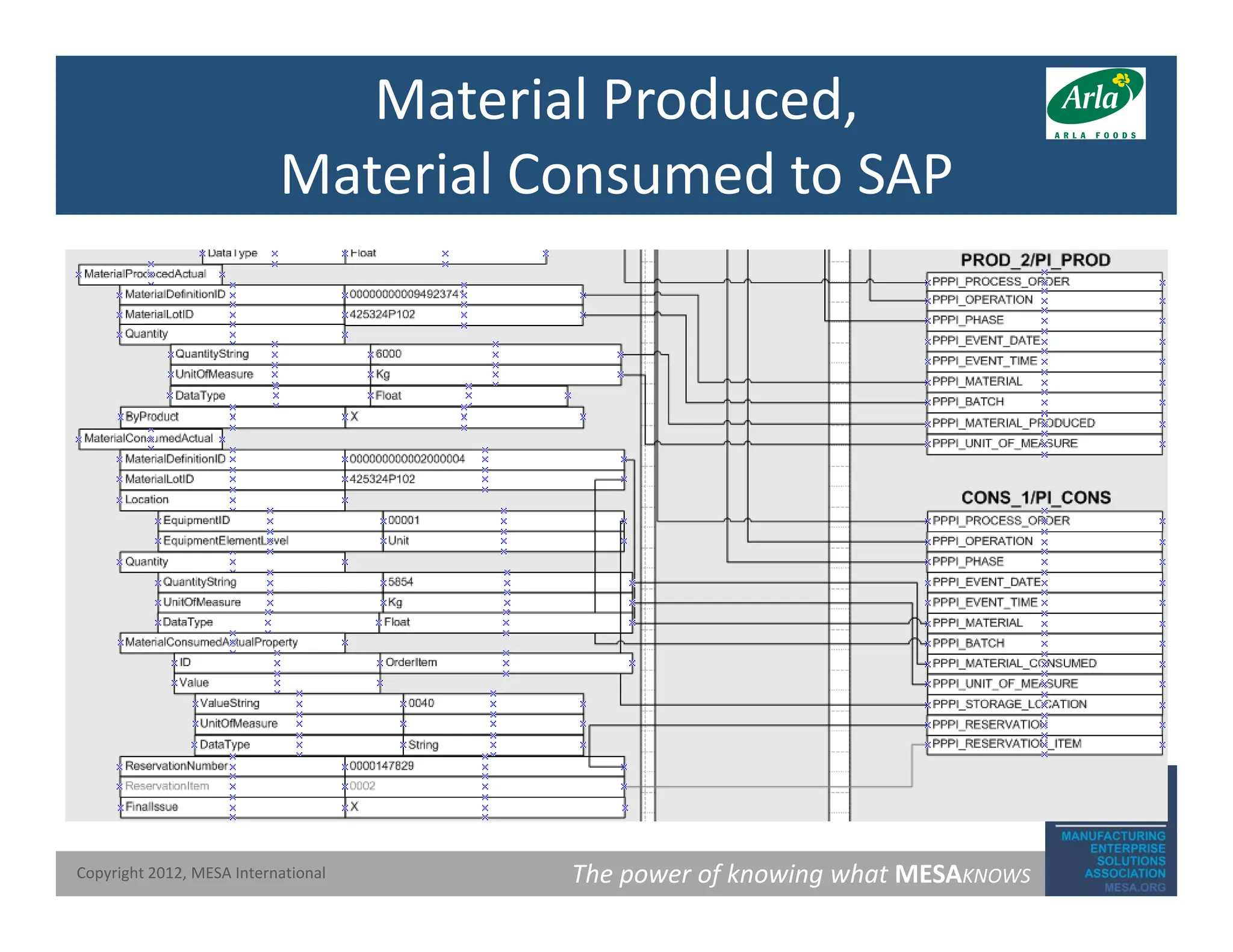

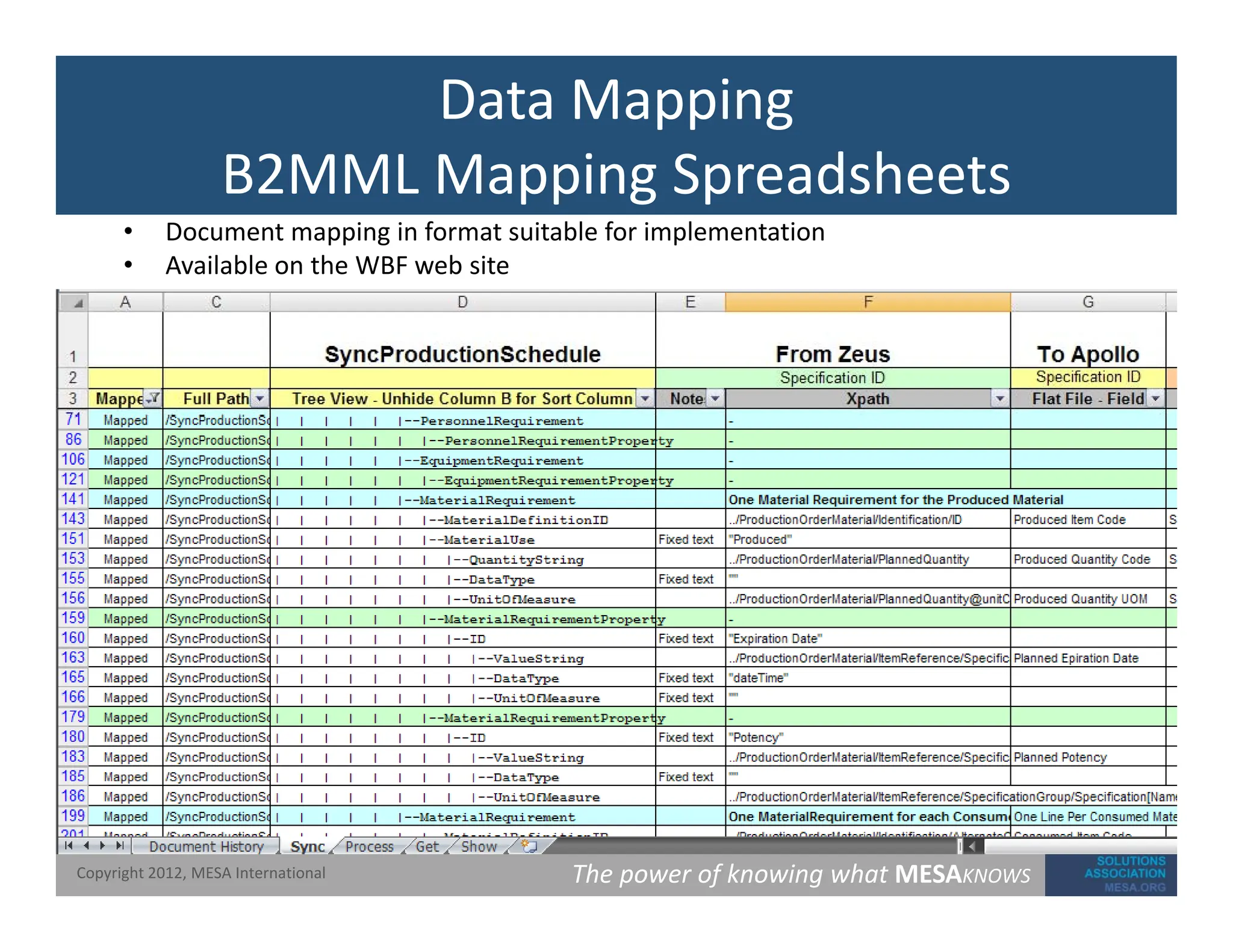

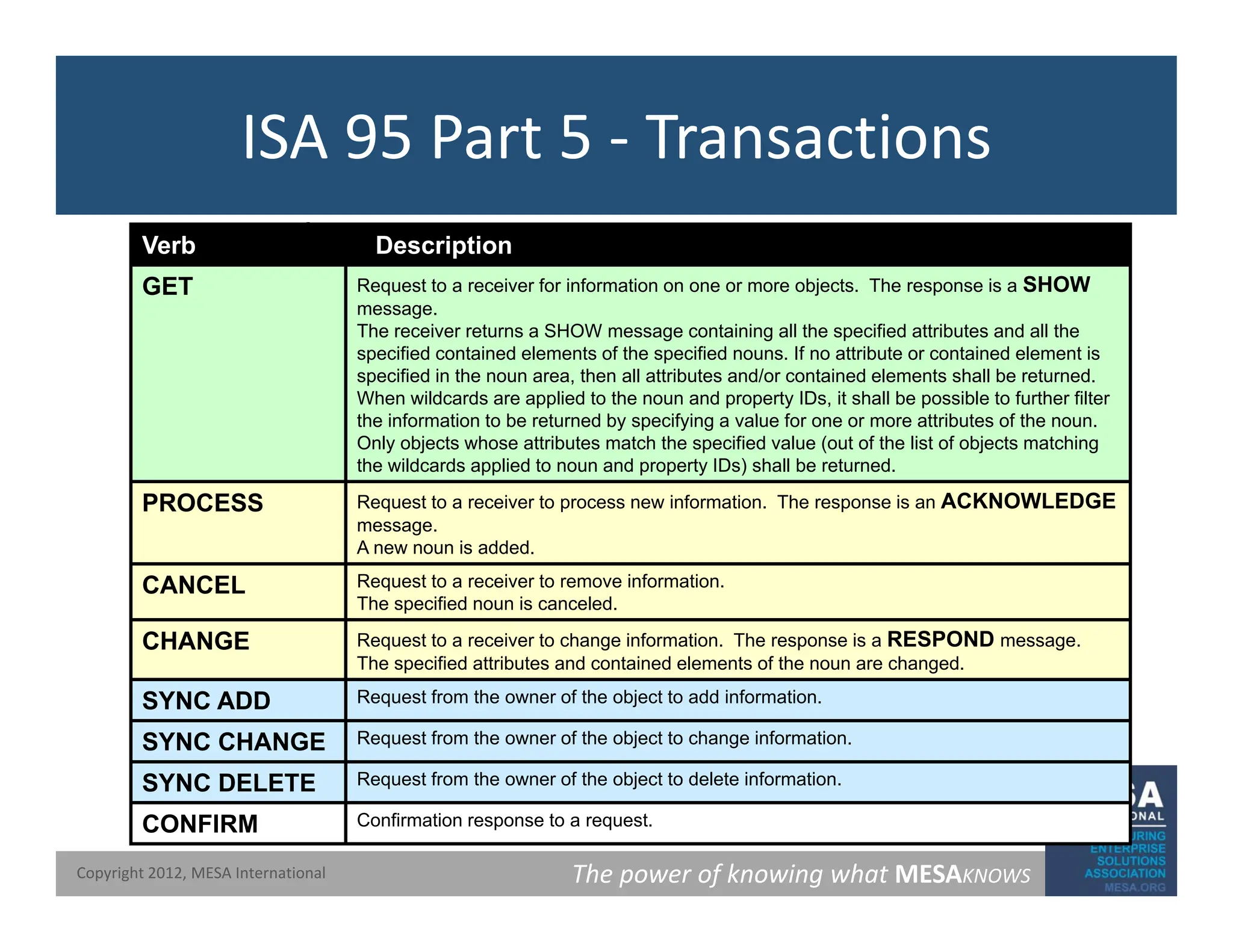

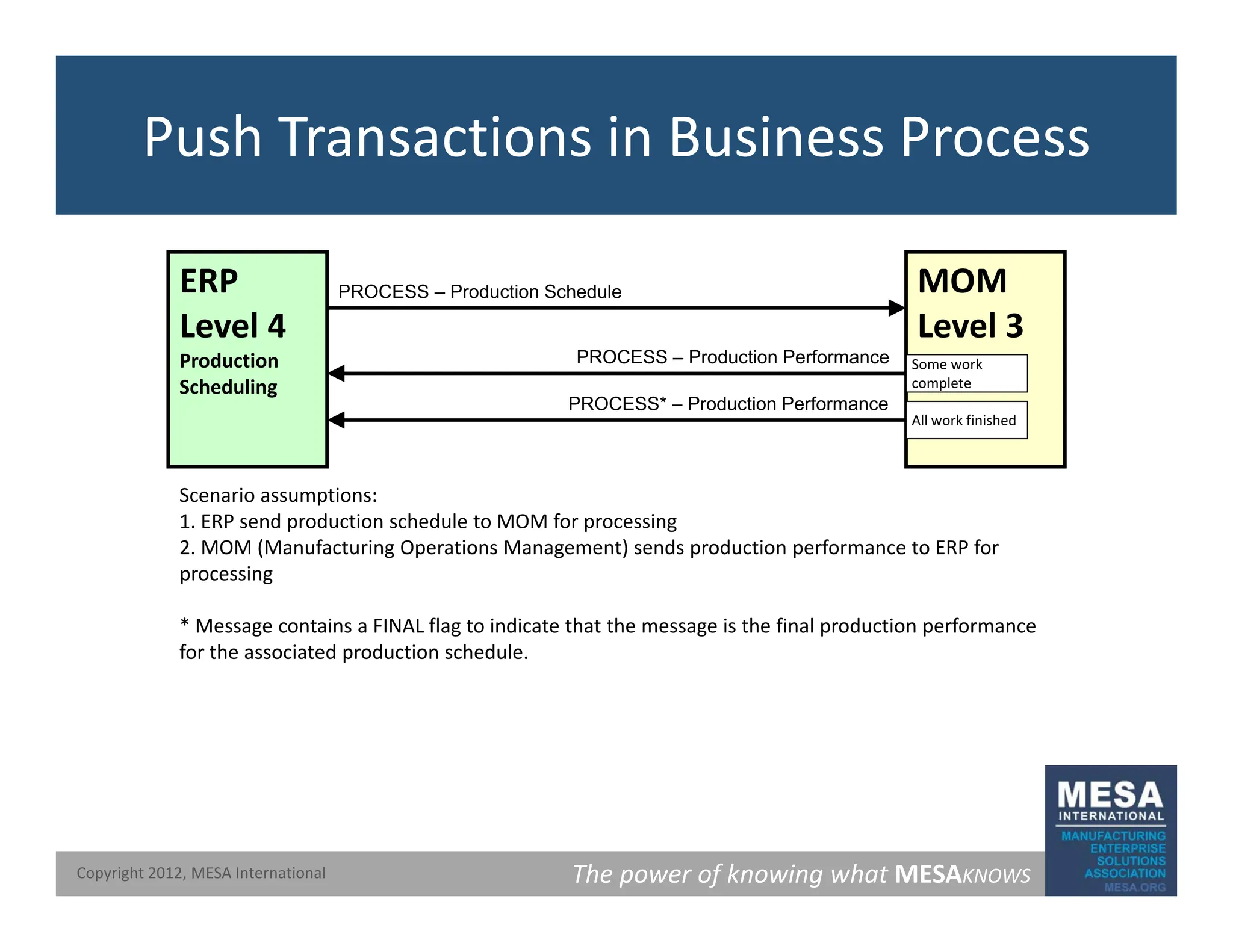

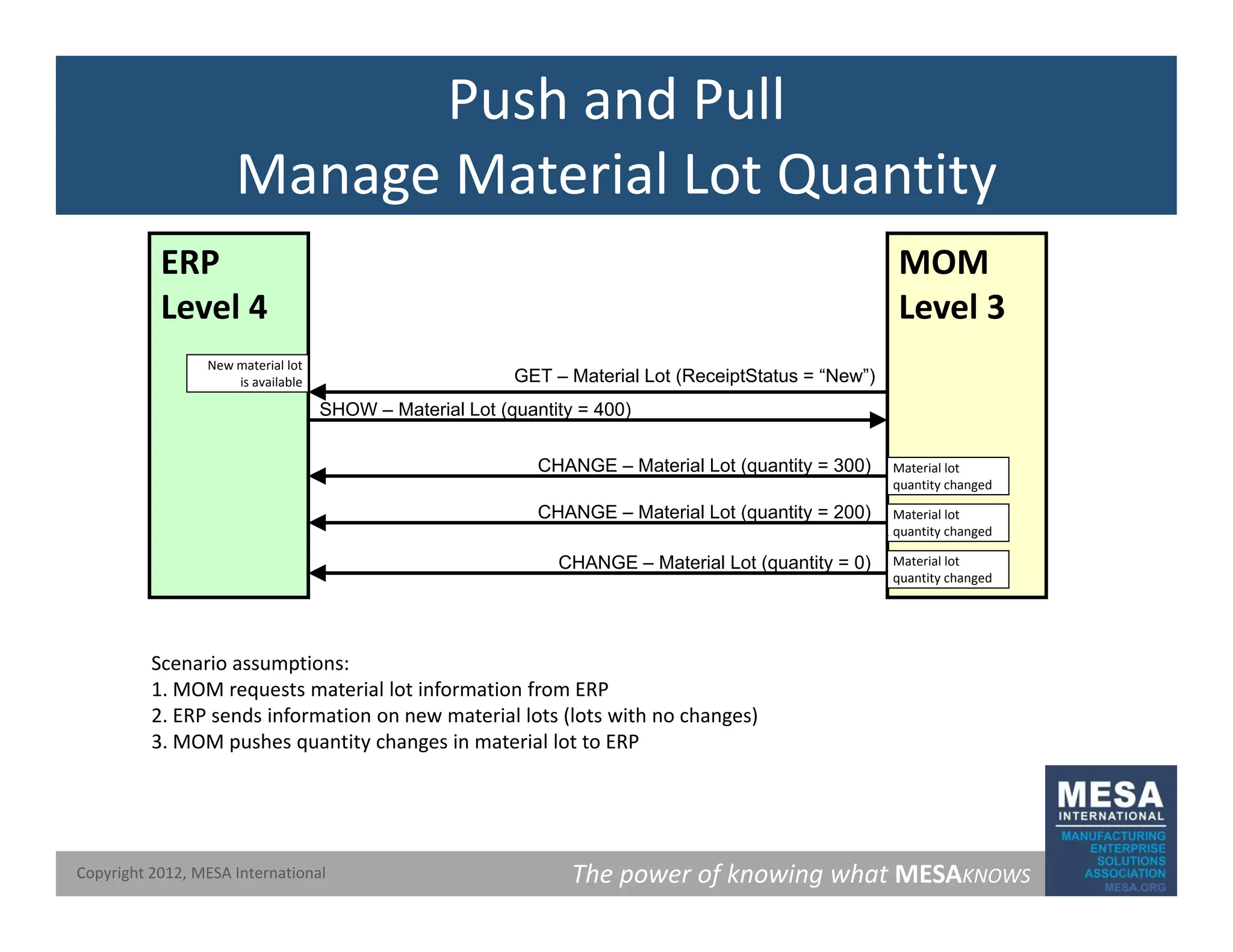

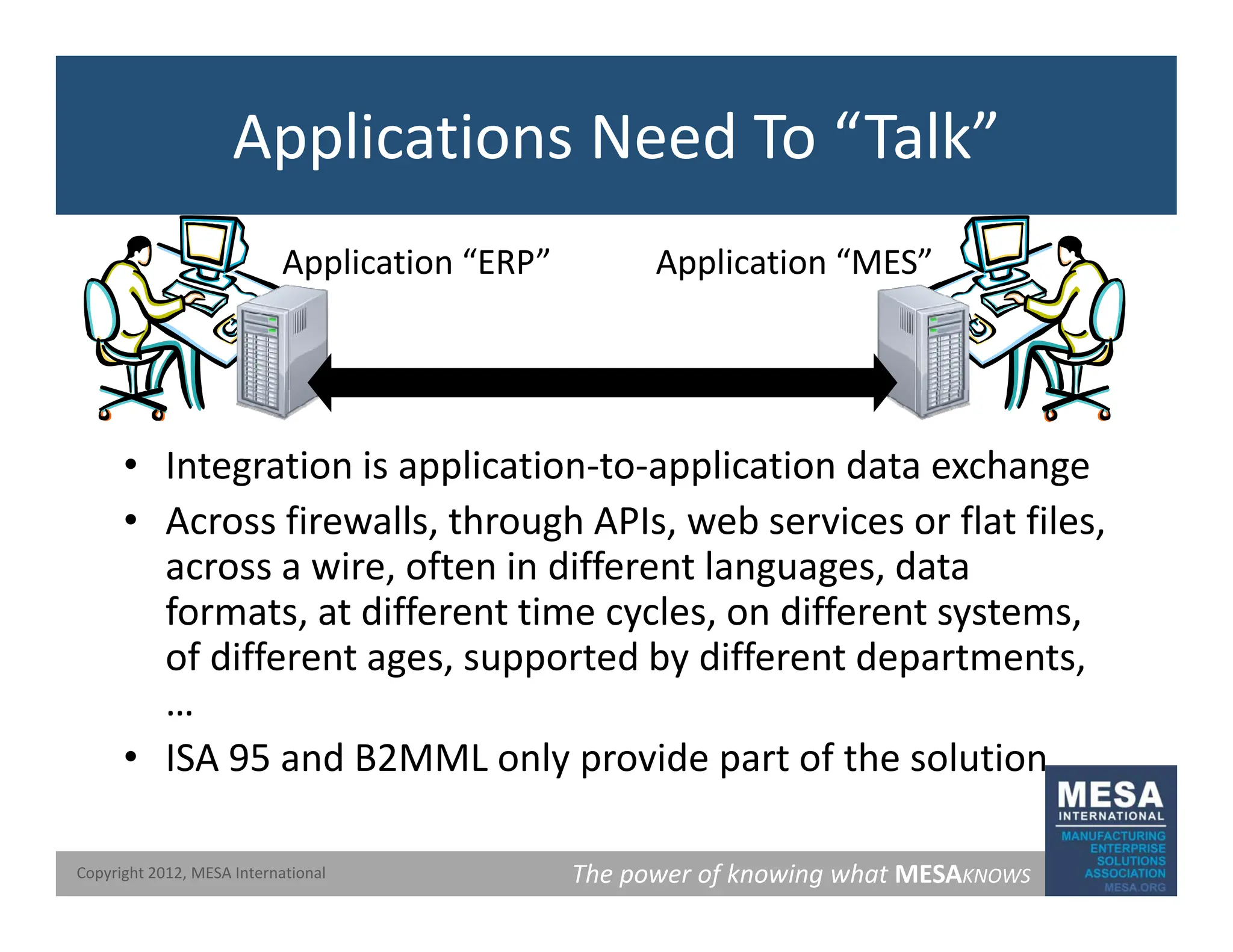

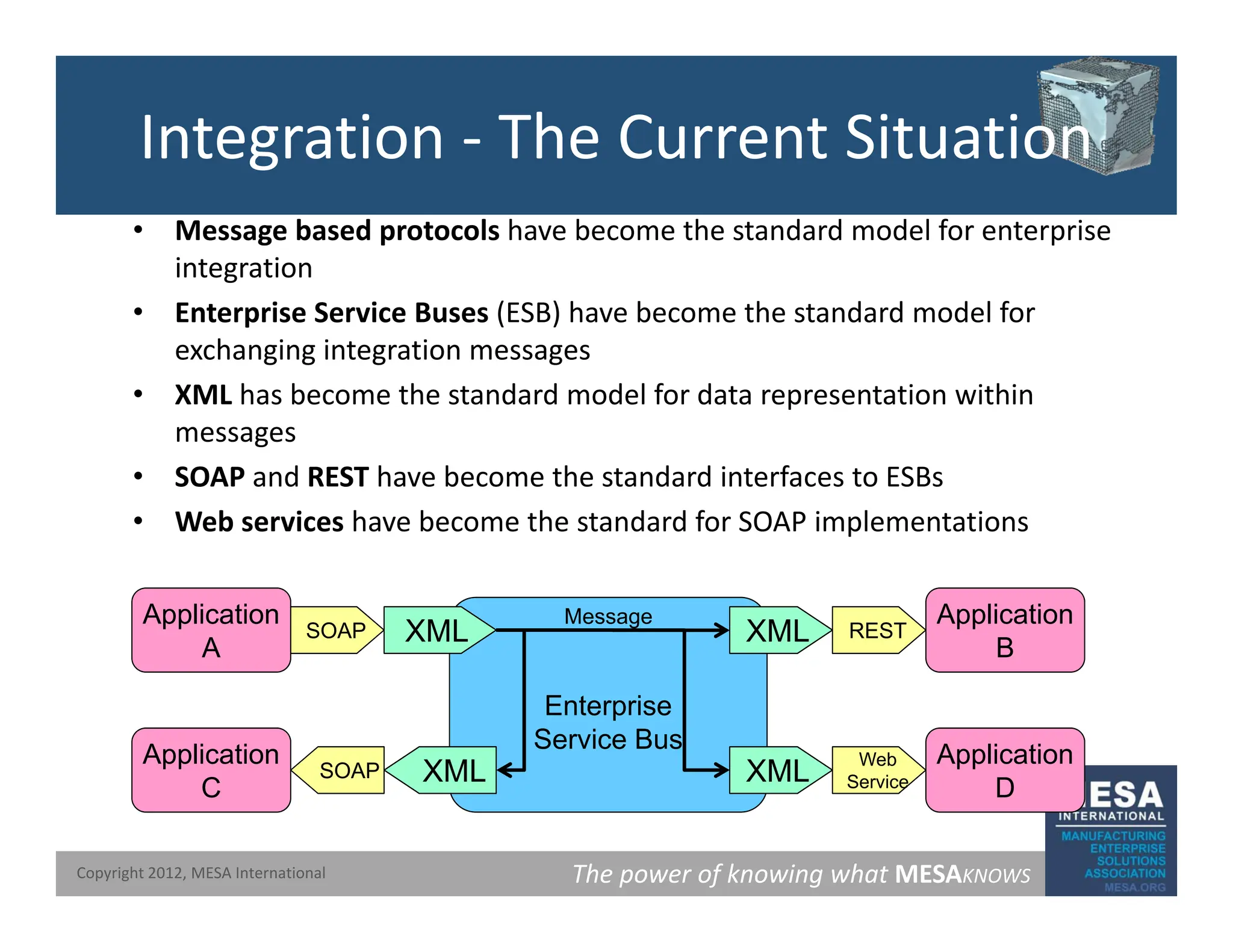

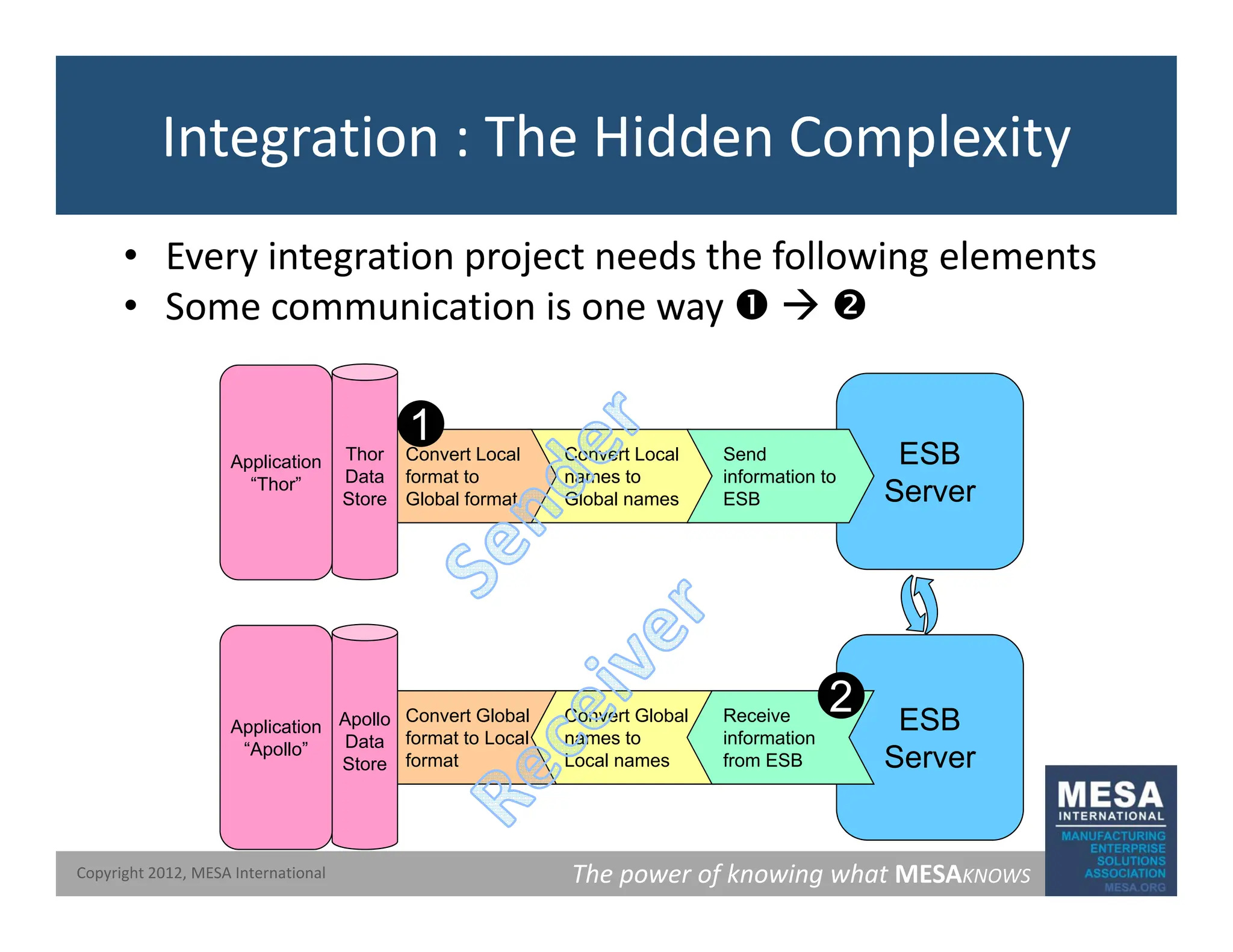

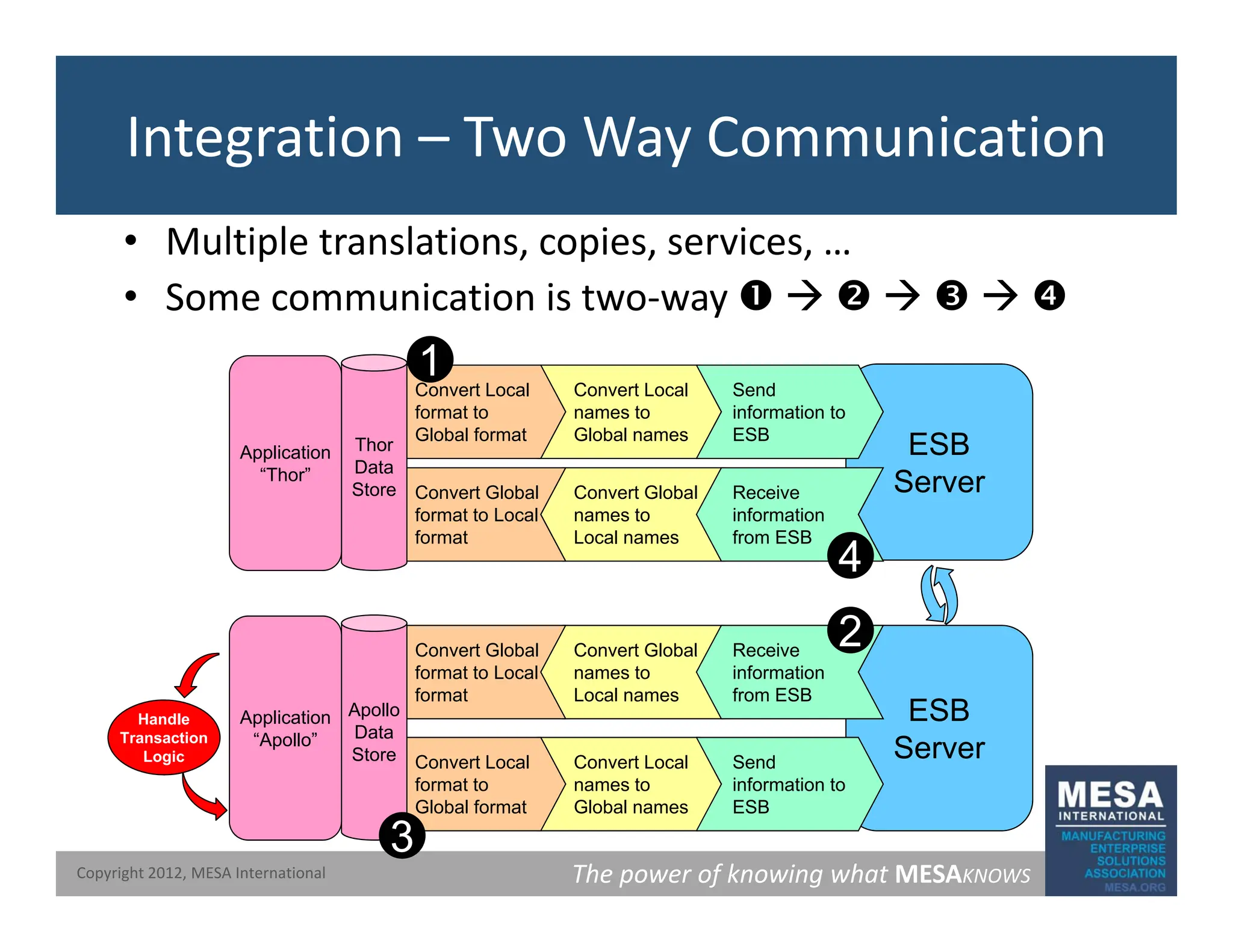

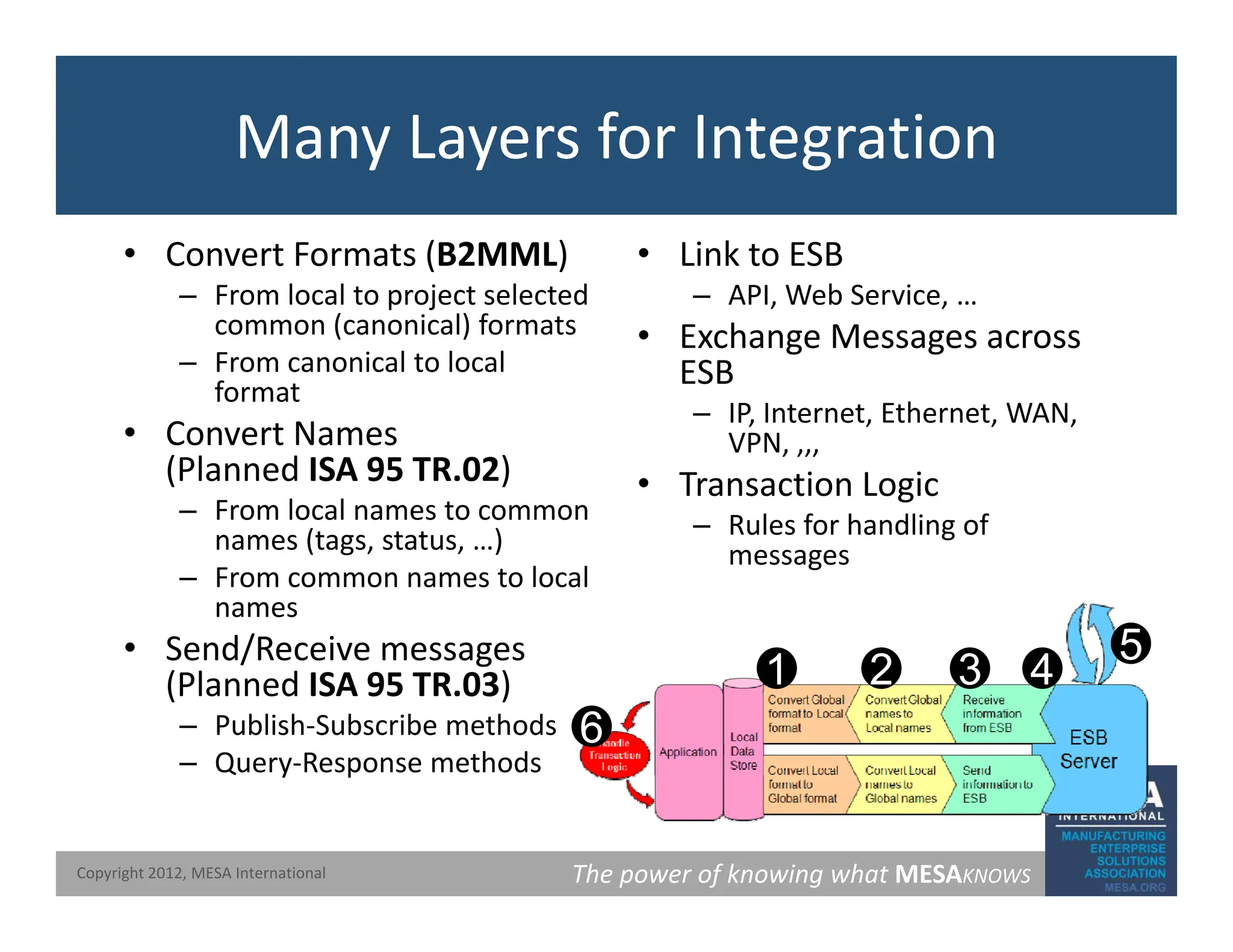

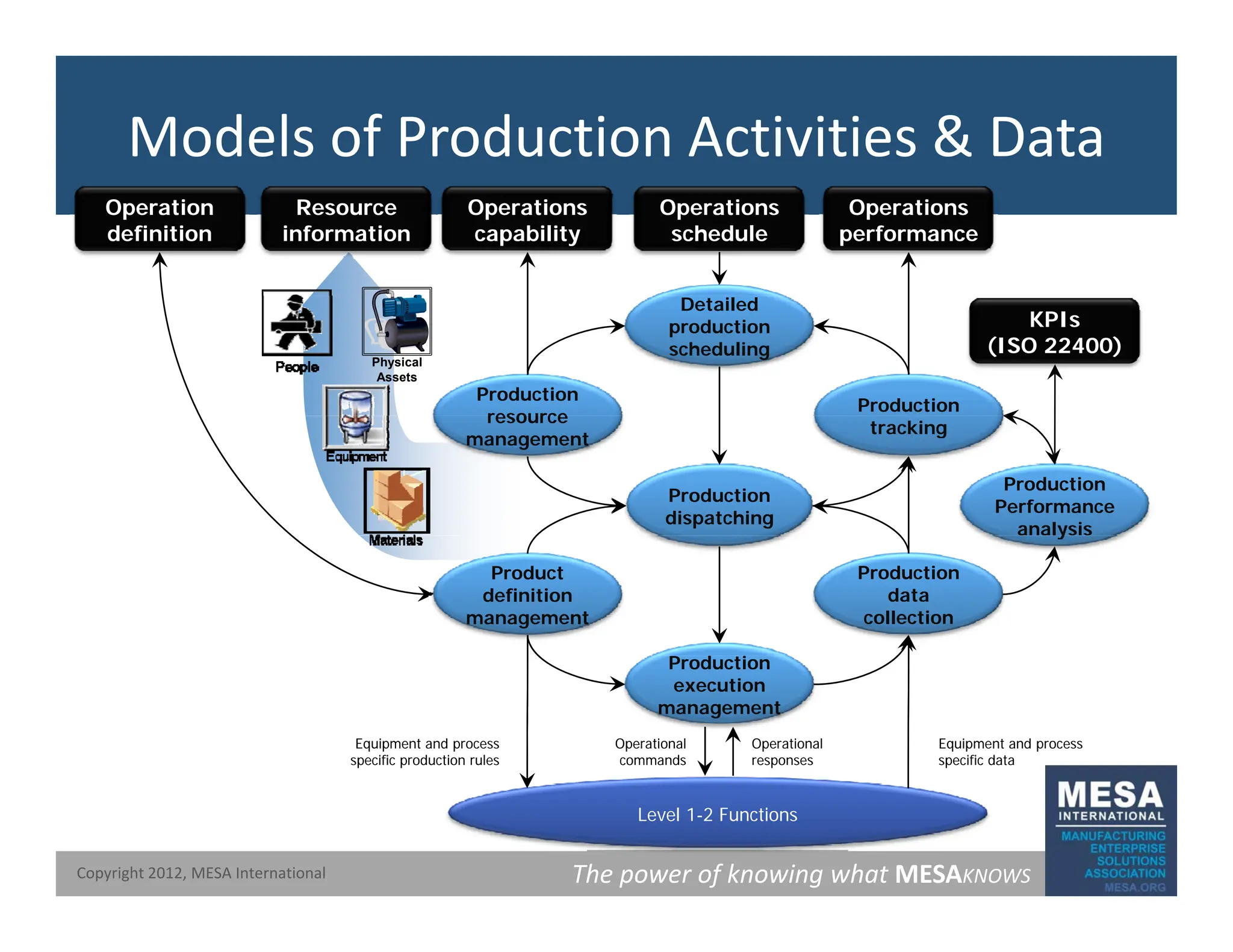

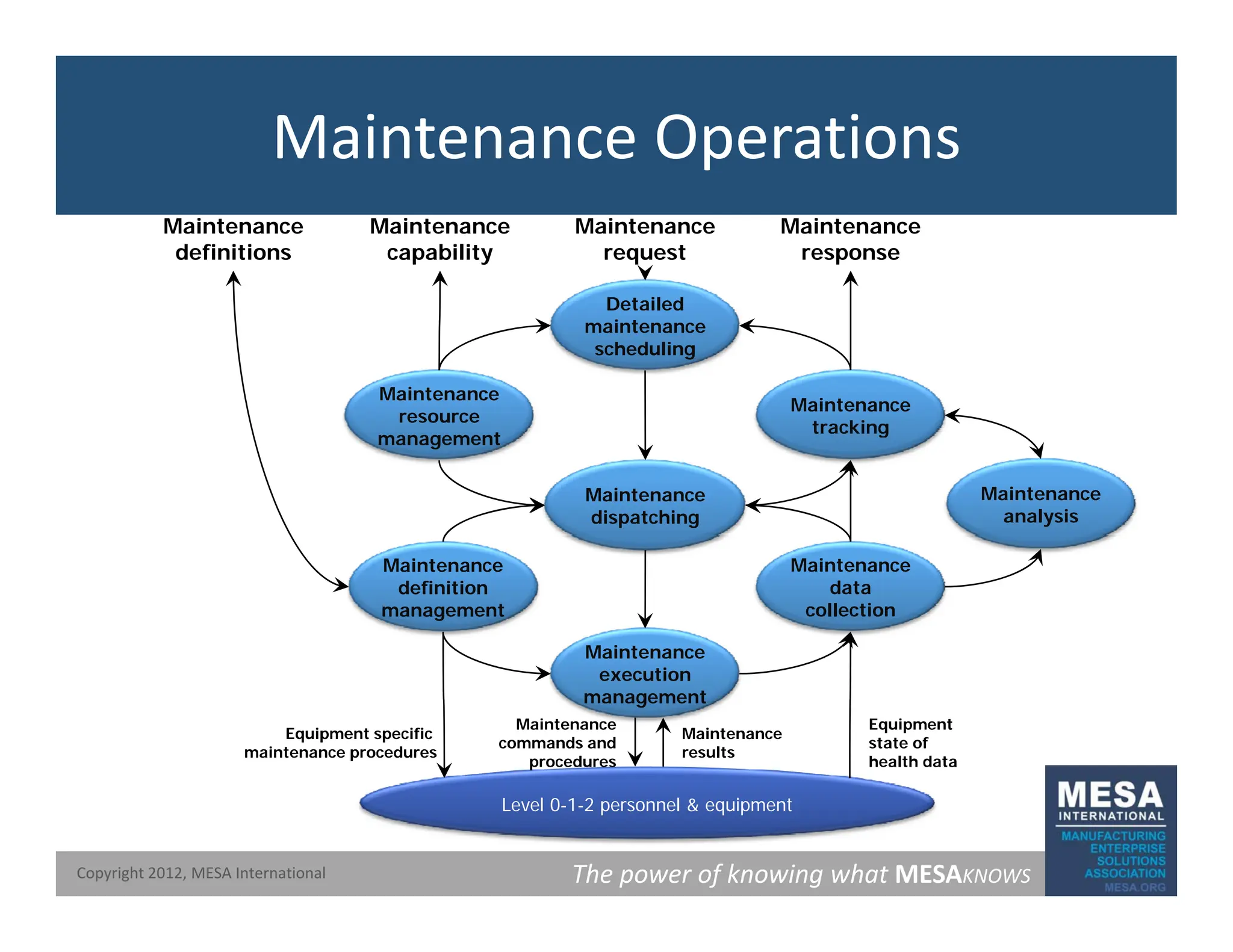

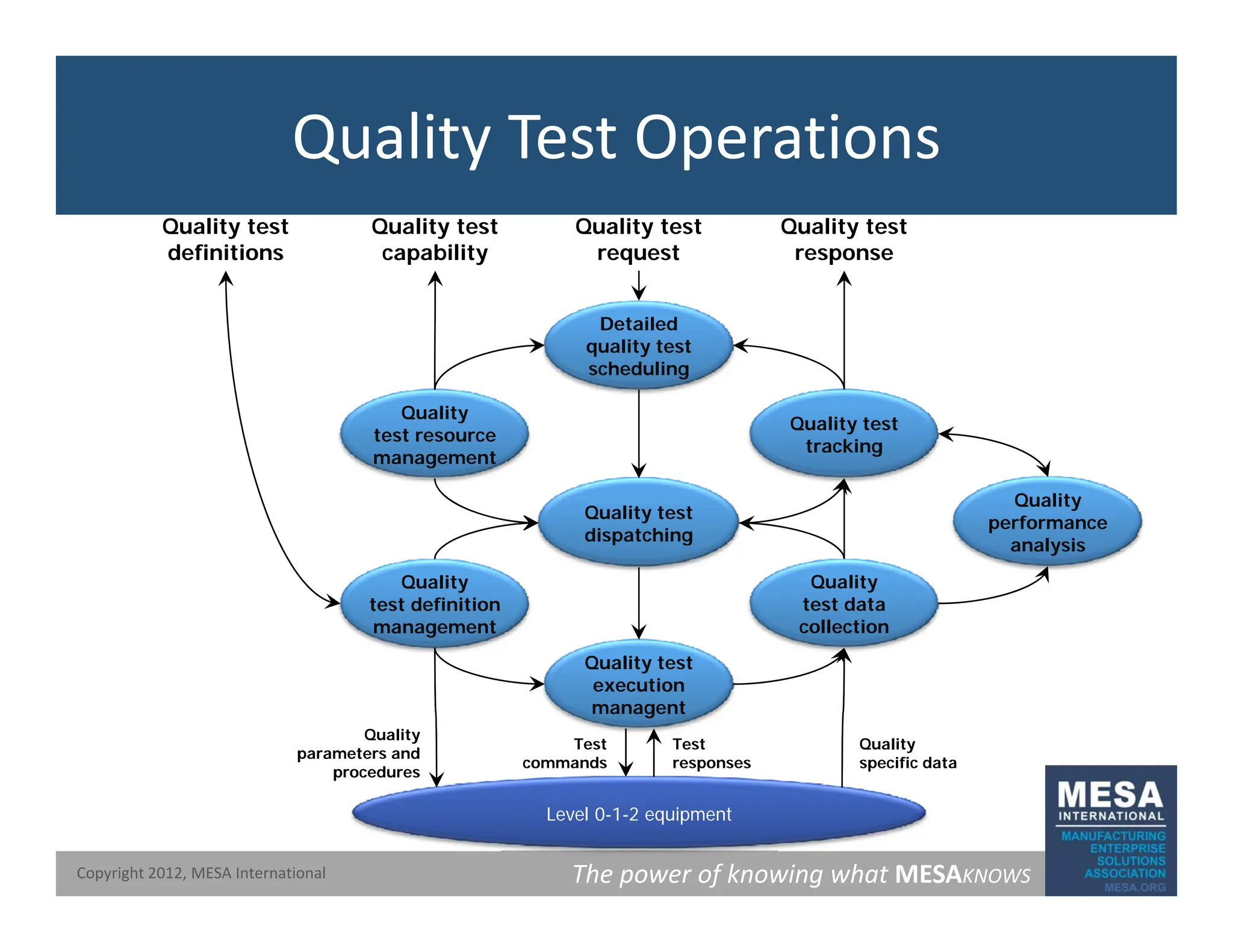

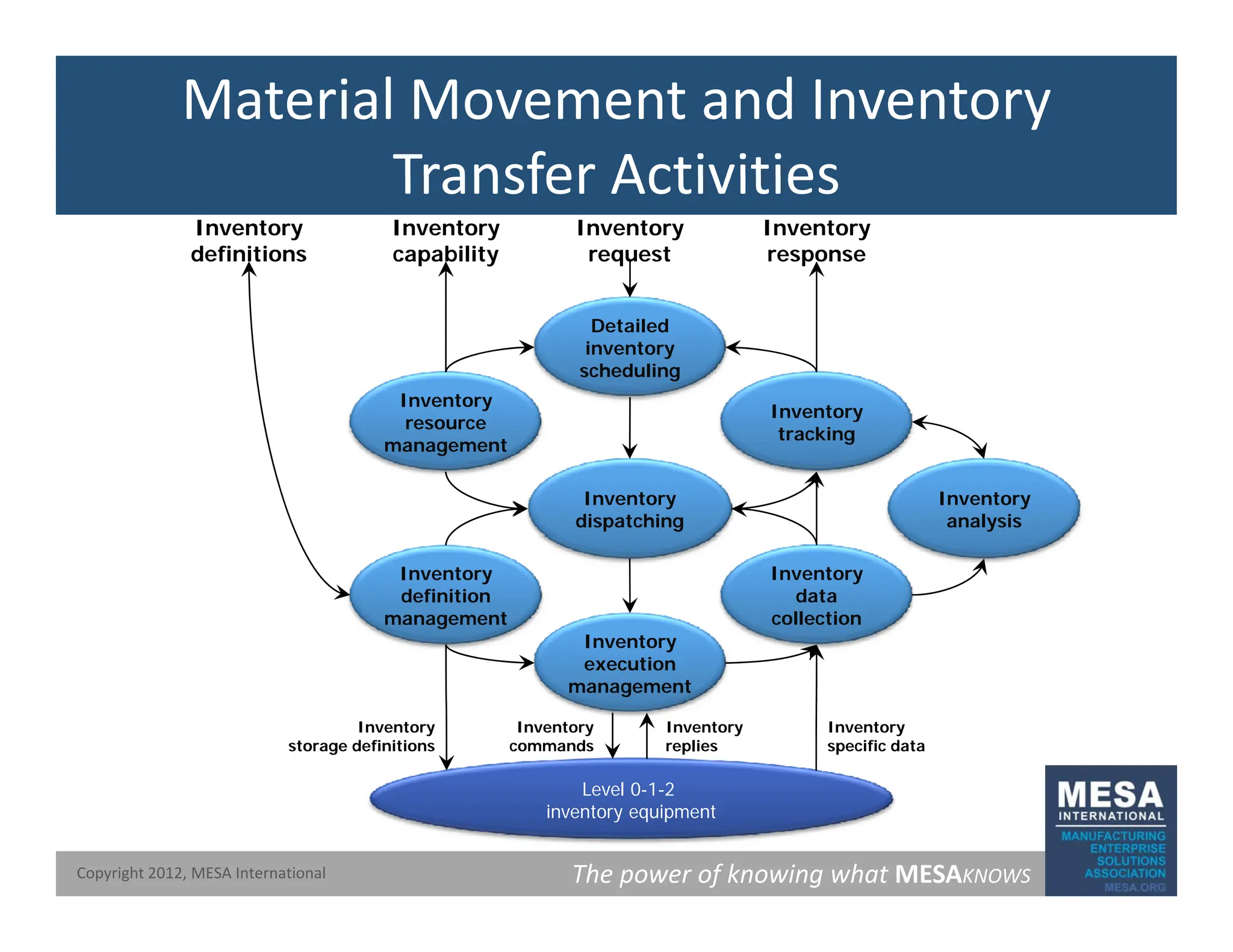

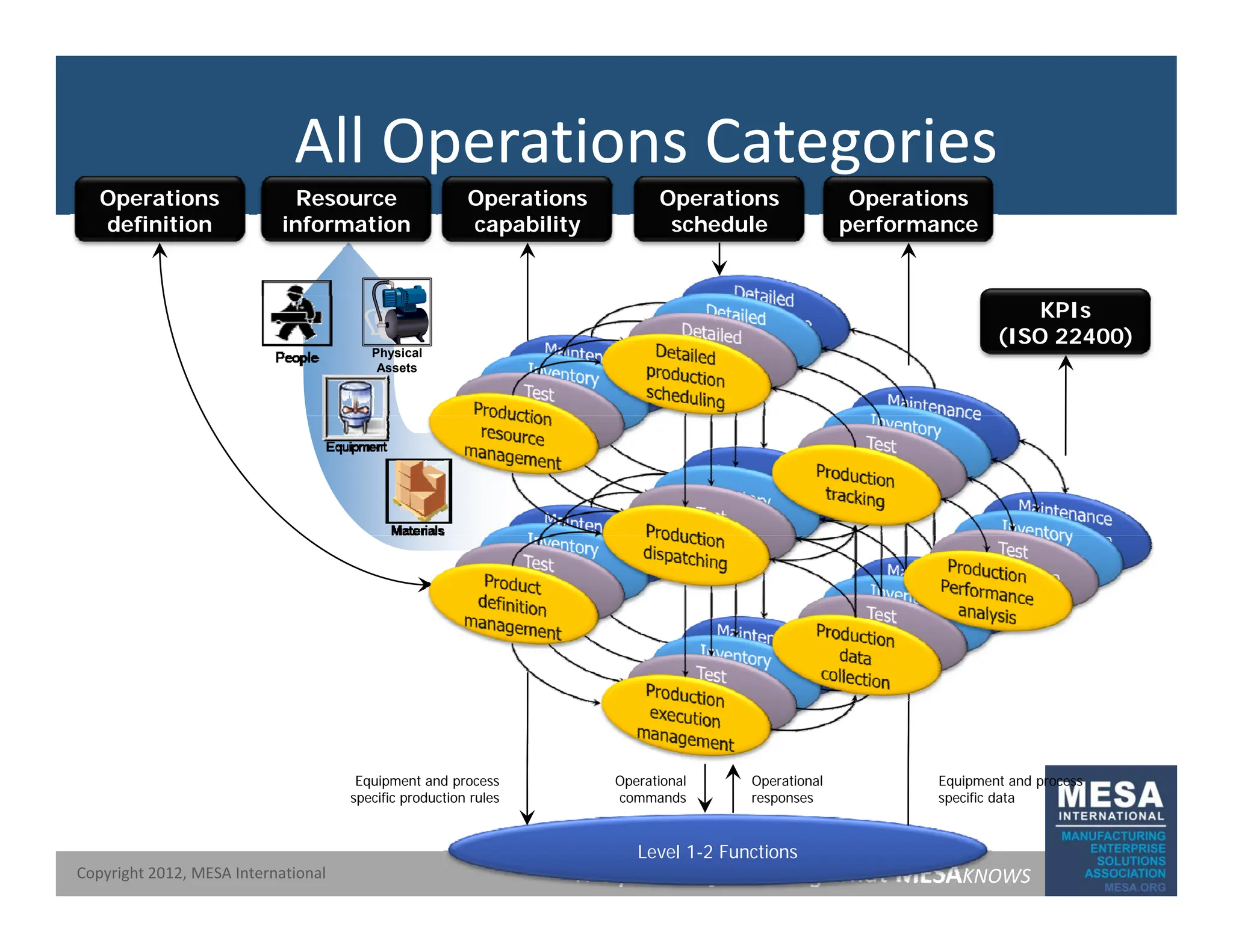

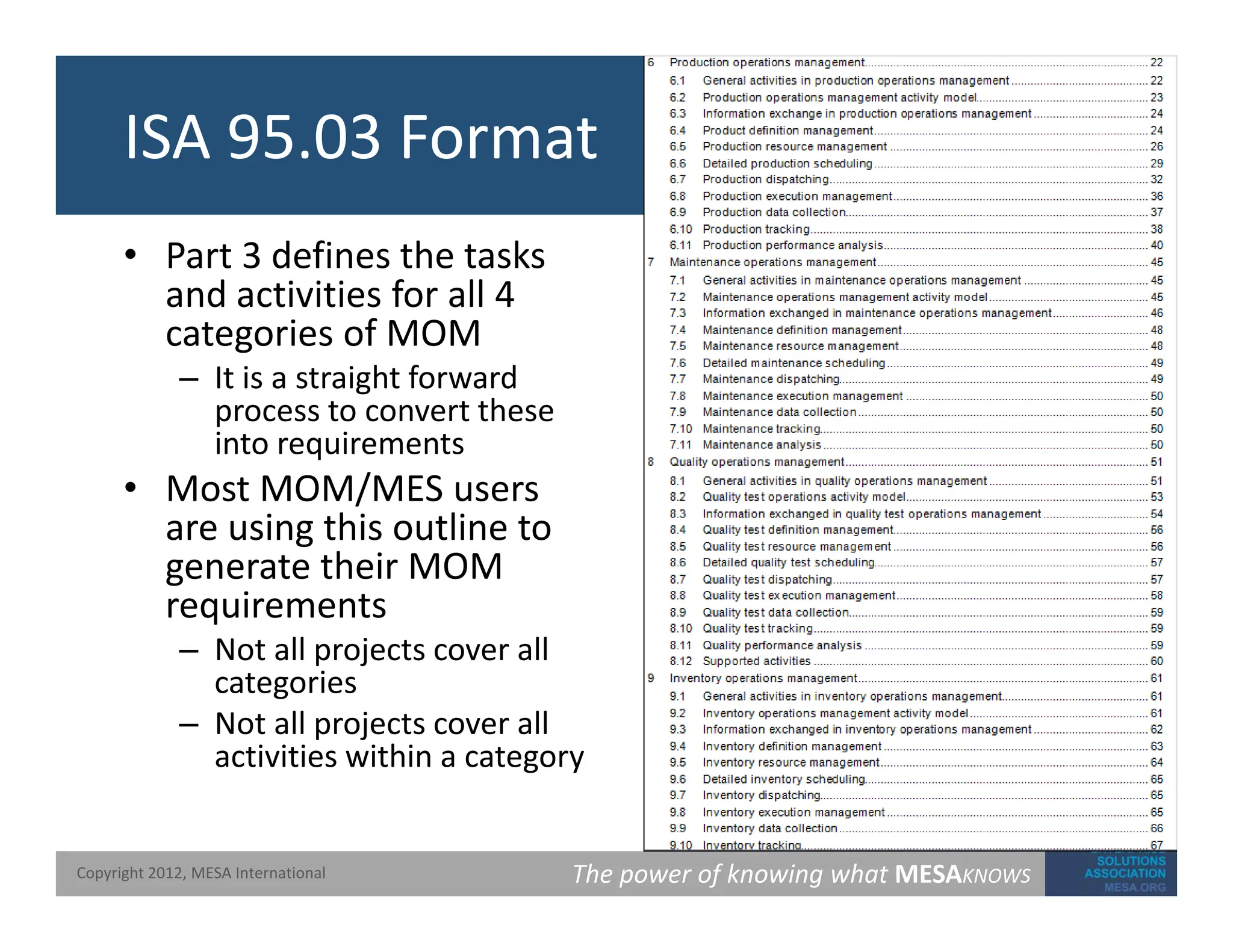

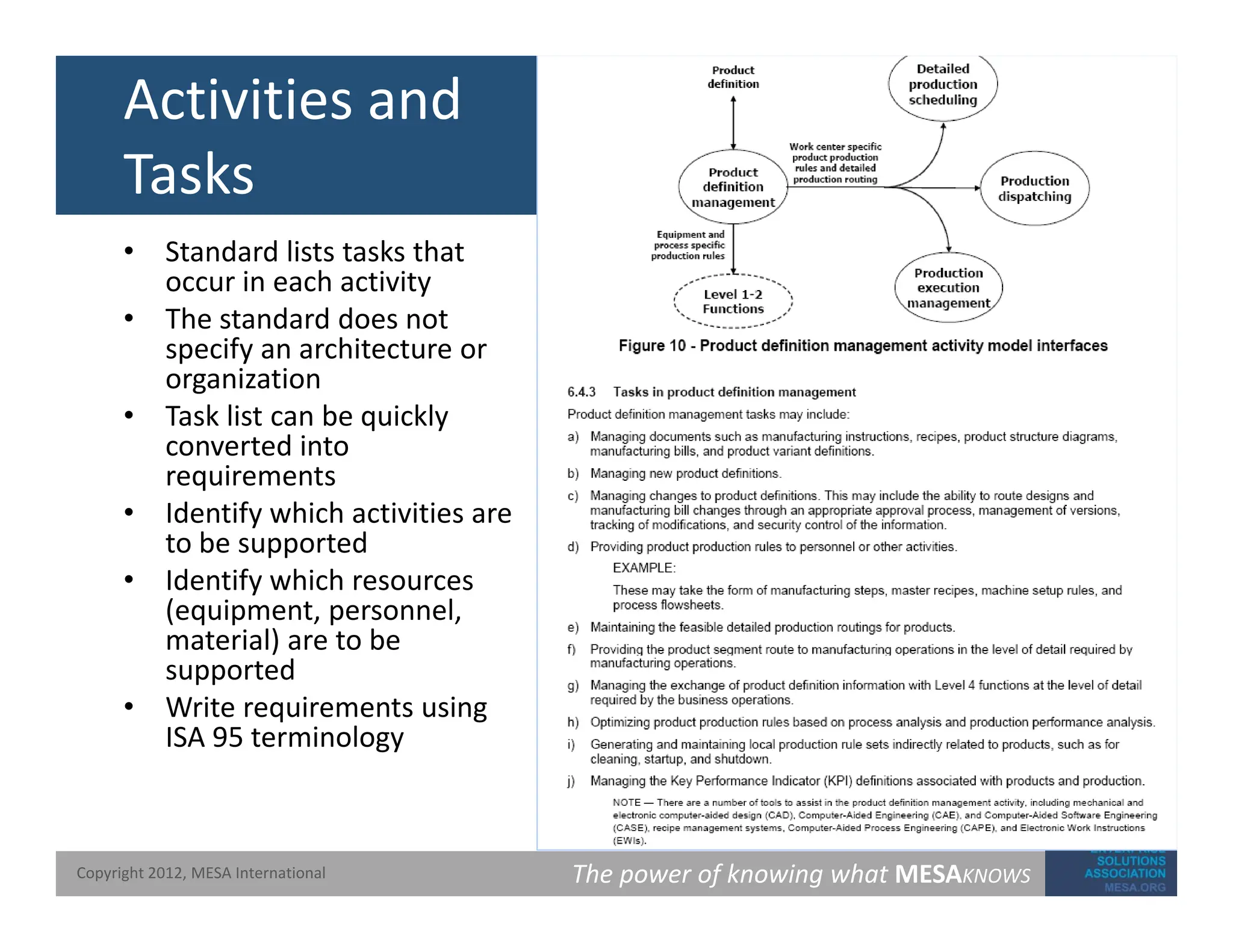

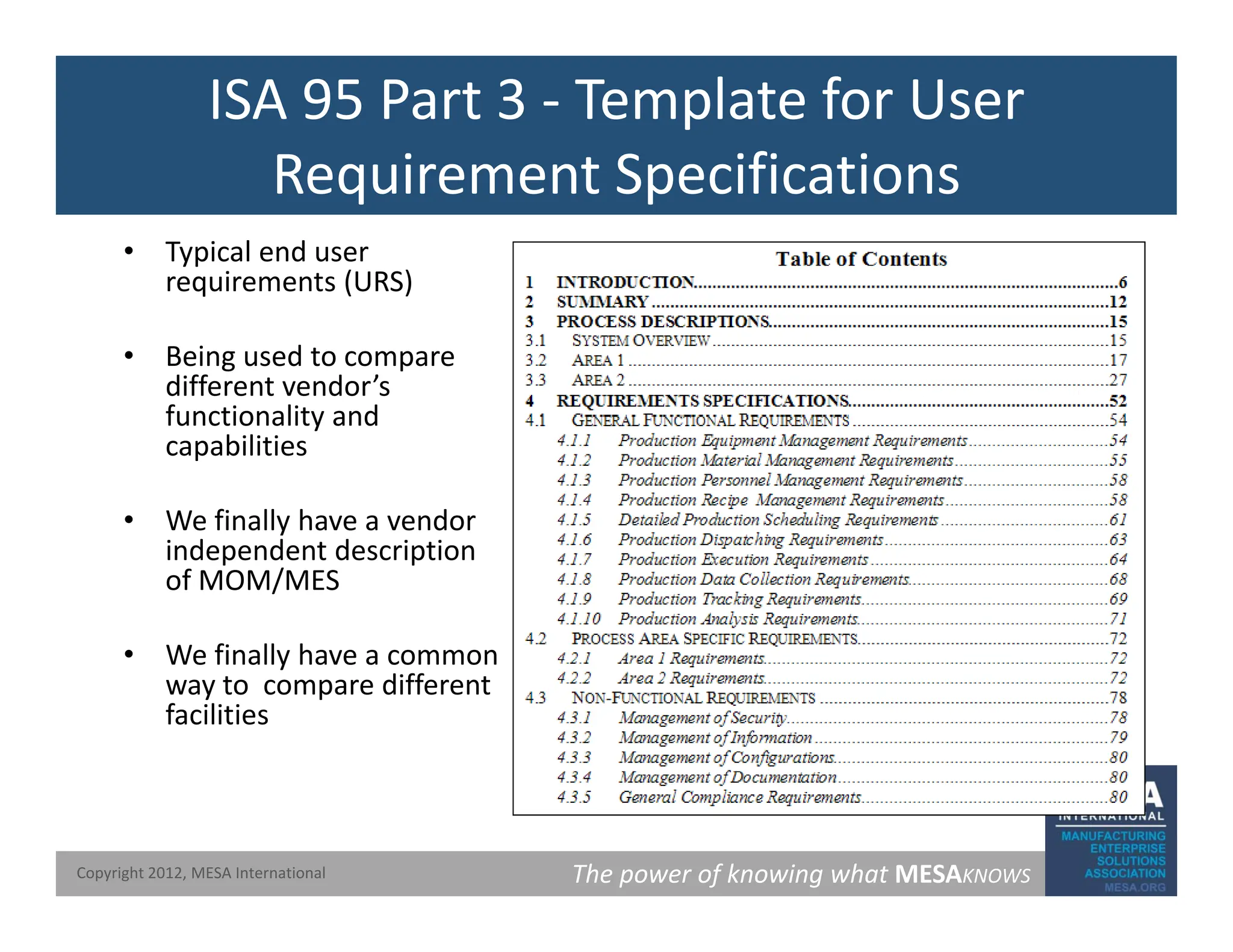

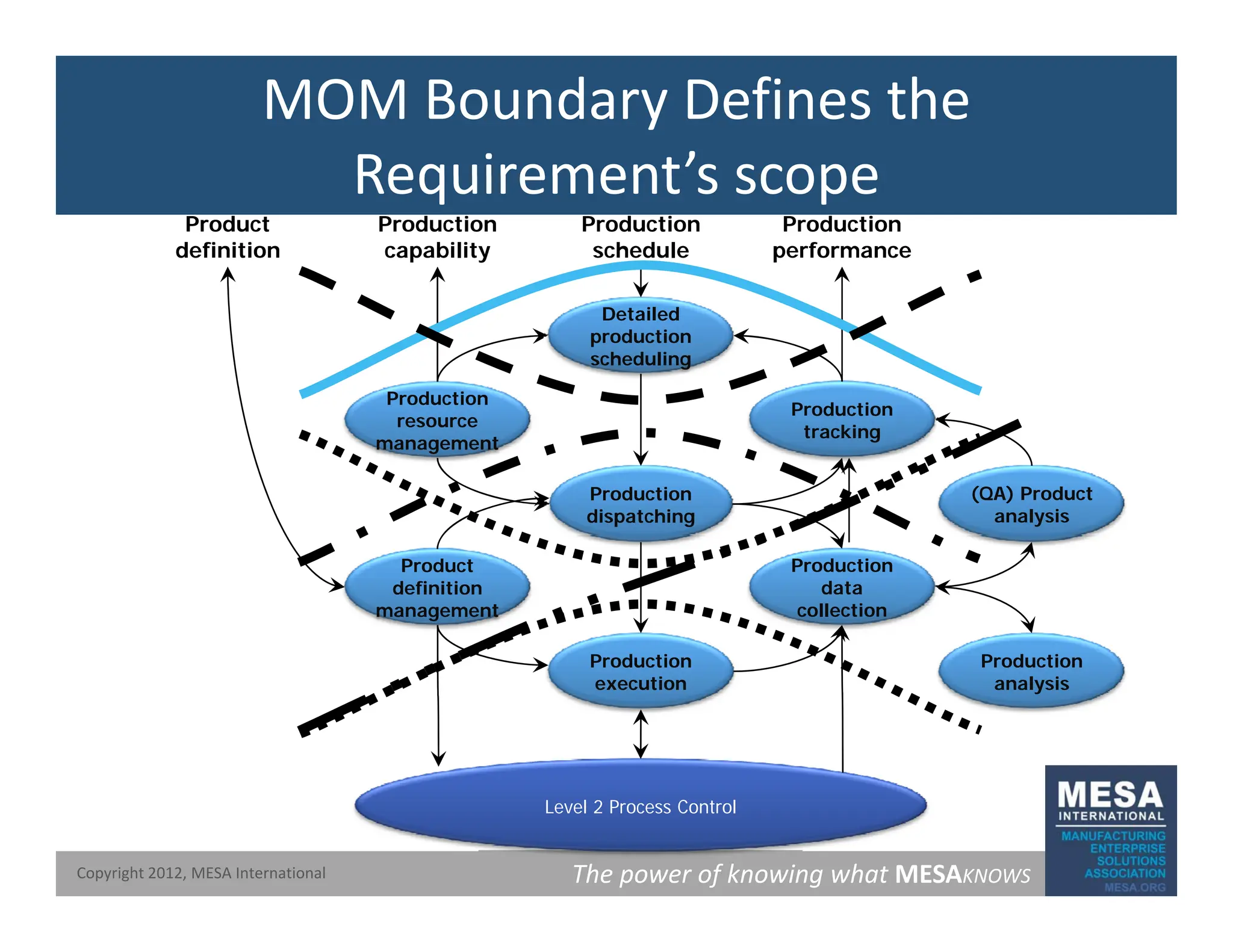

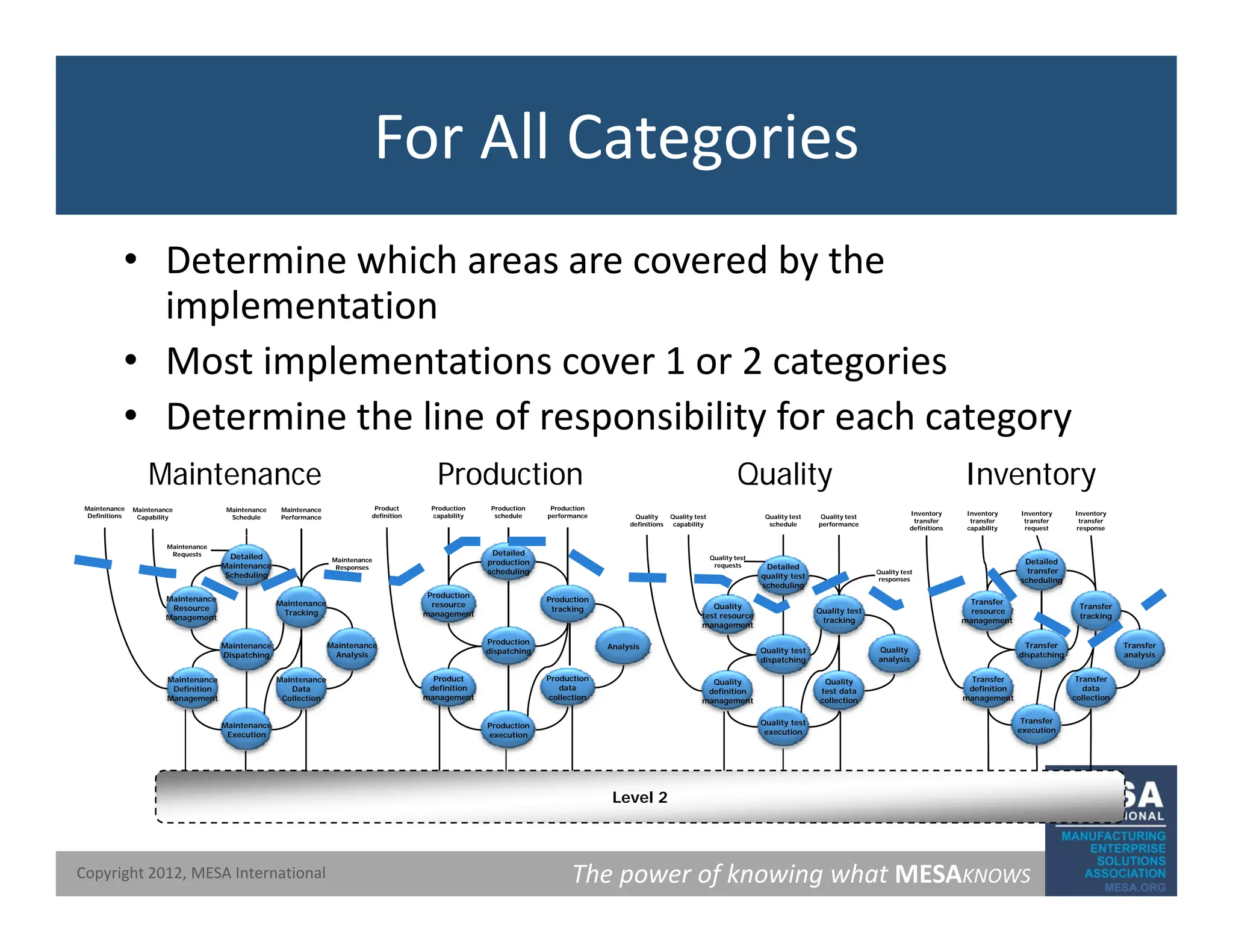

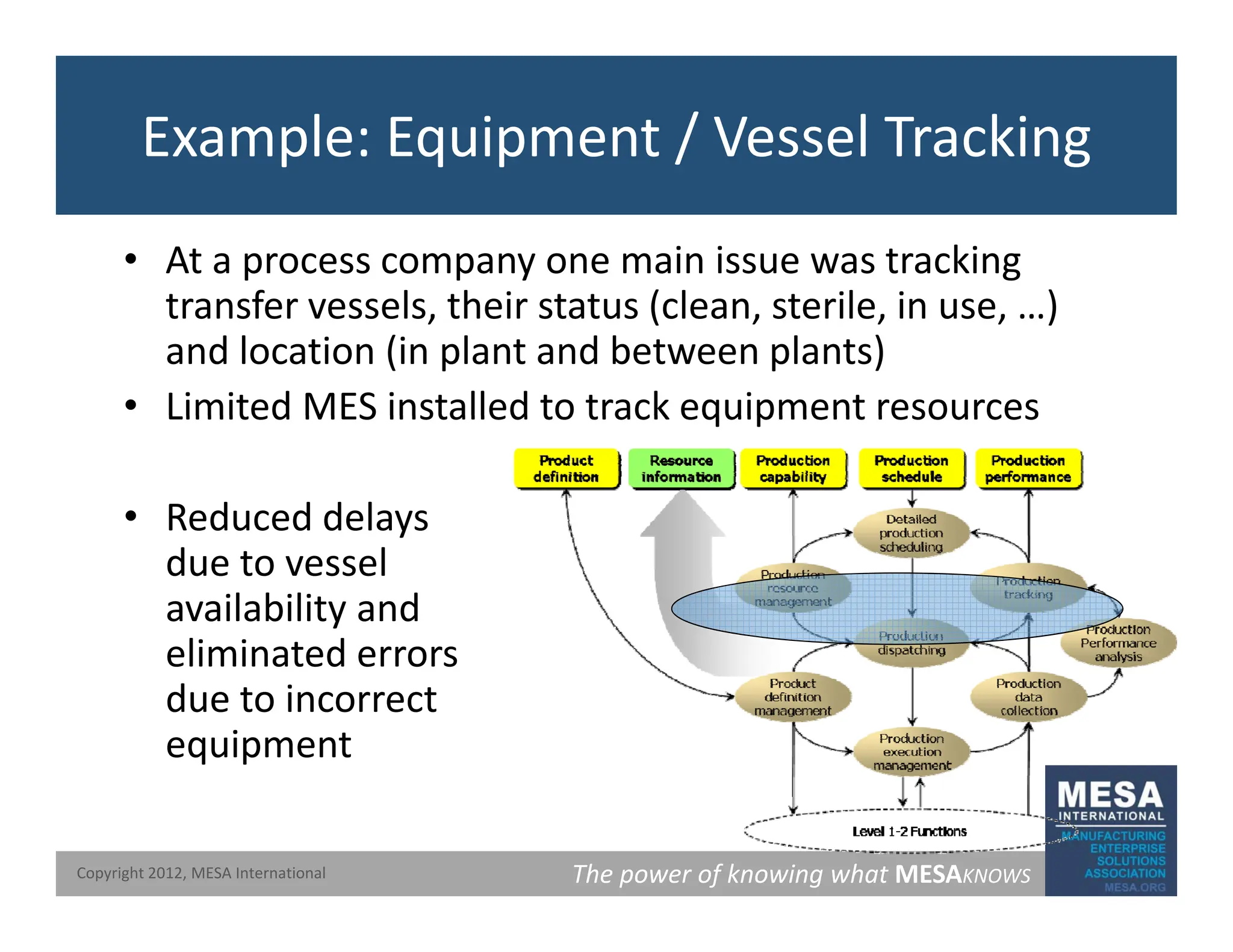

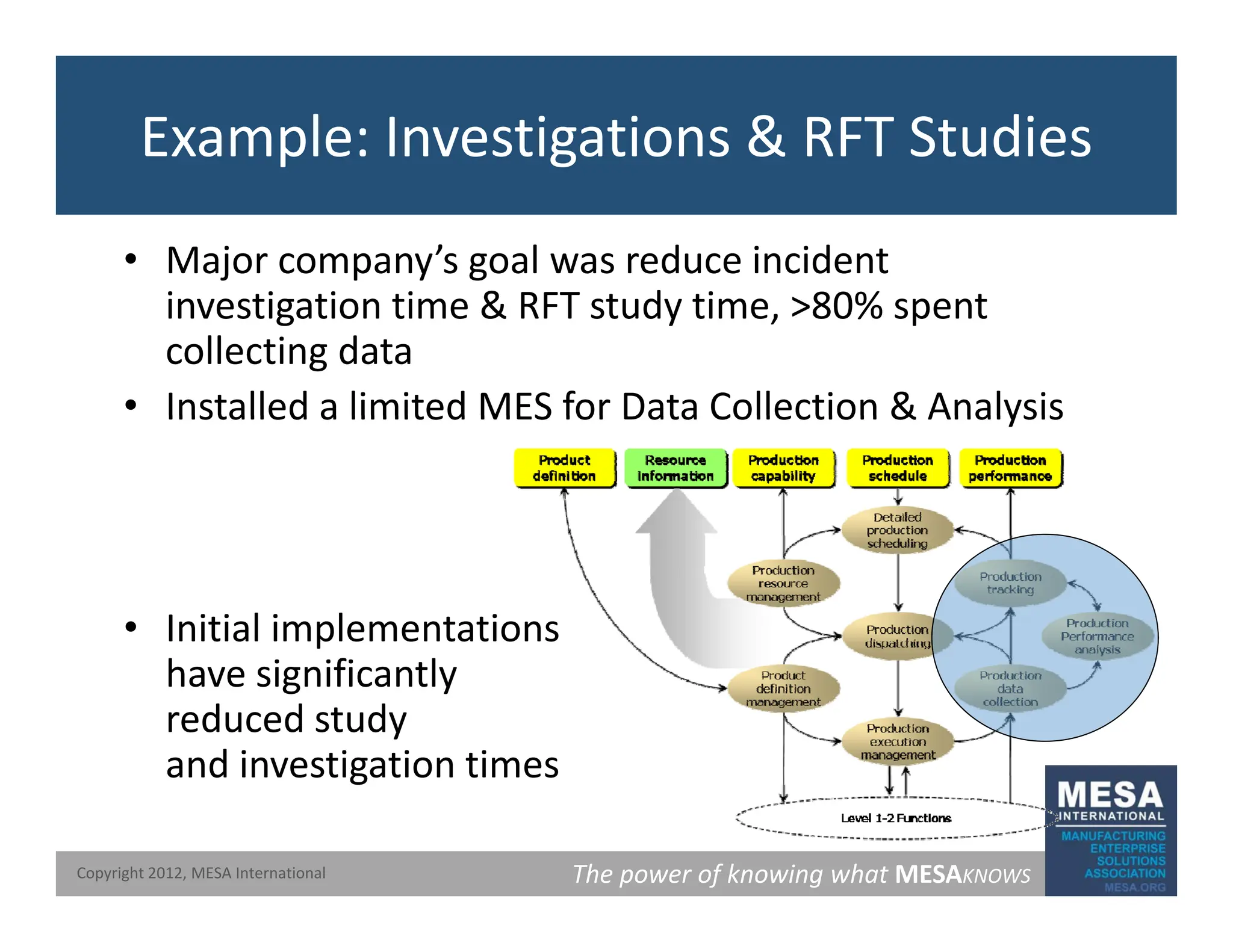

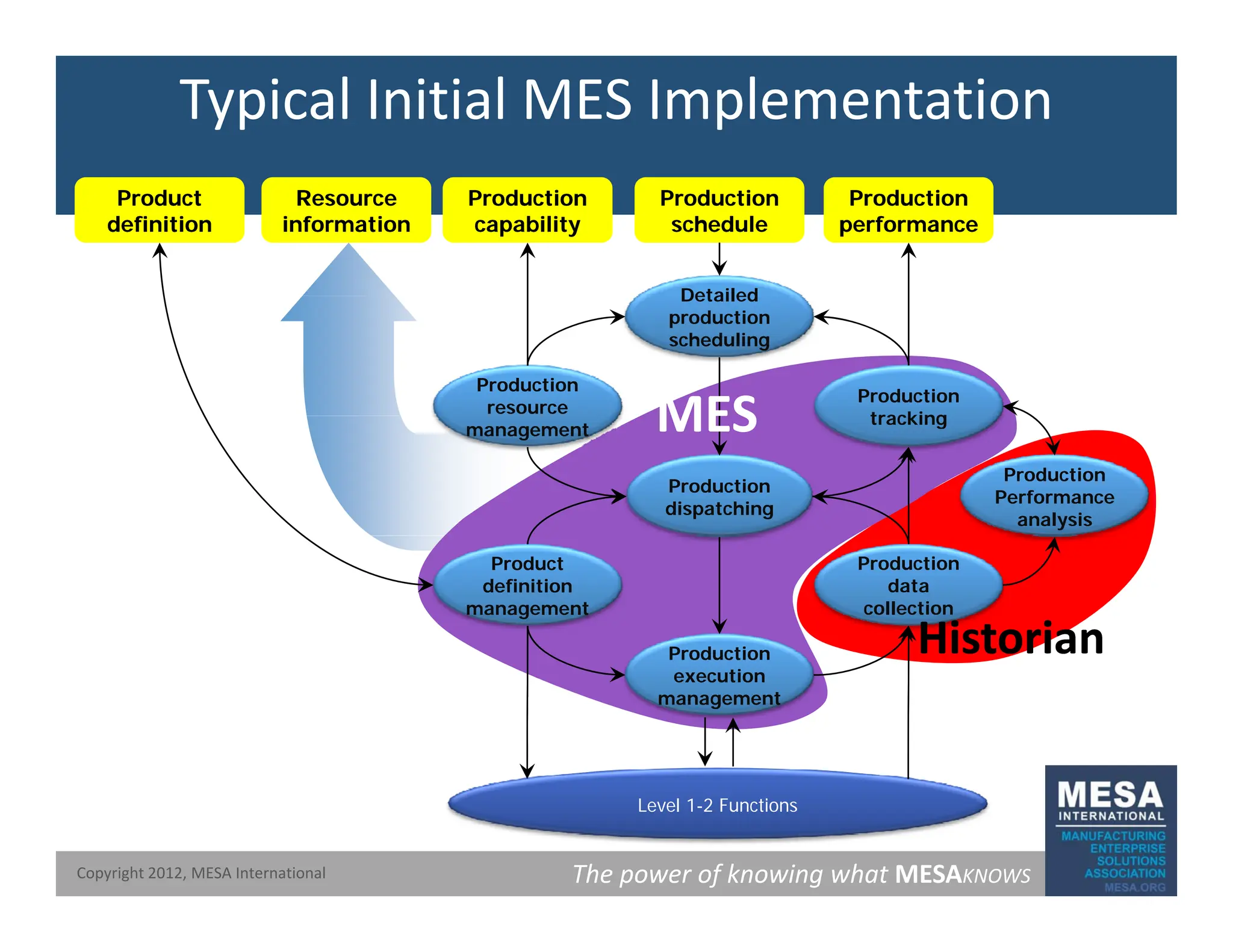

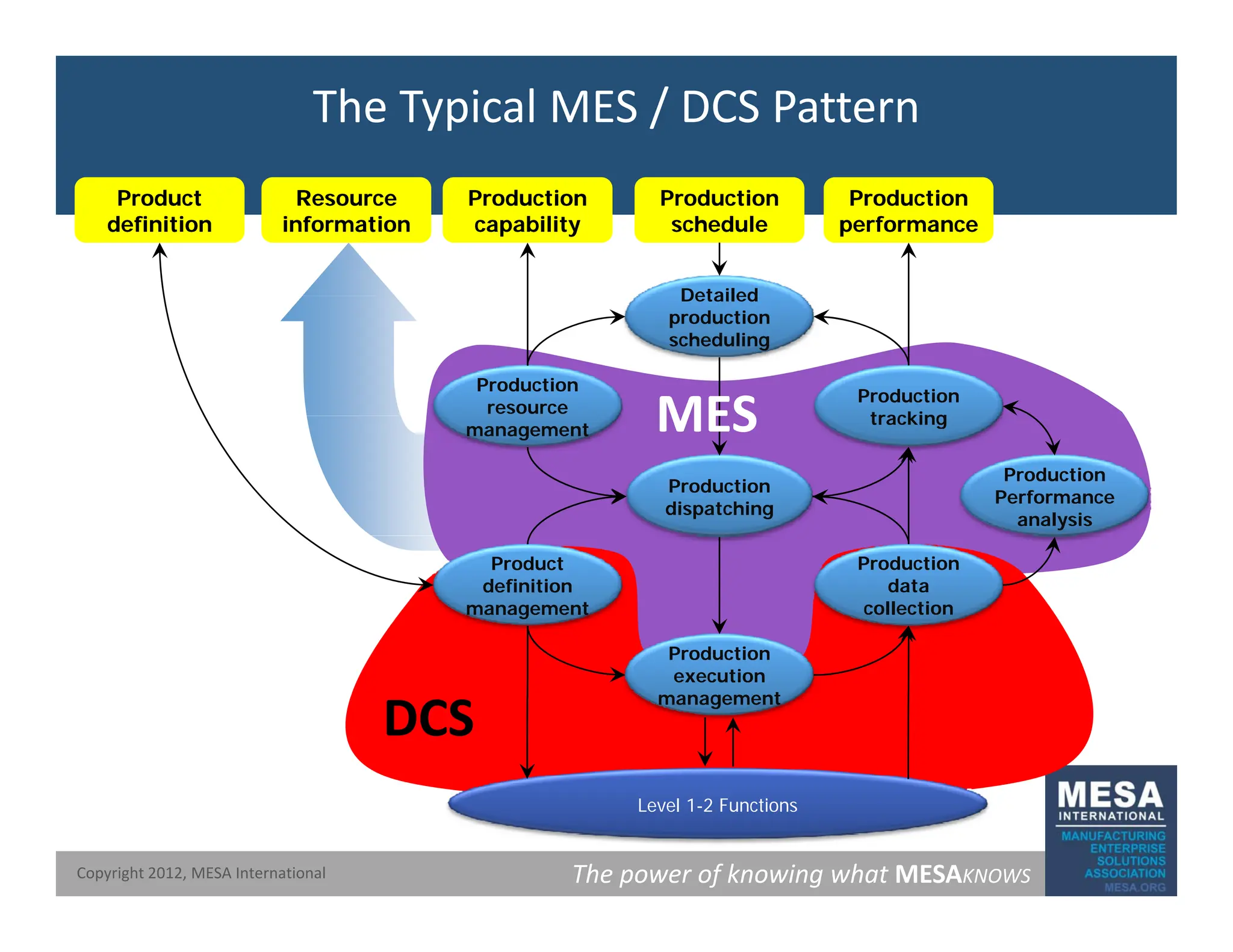

The document outlines the ISA 95 standard for enterprise-control system integration, emphasizing its benefits in defining manufacturing operations and improving communication between business and manufacturing systems. It also discusses the evolution of manufacturing execution systems (MES) into manufacturing operations management (MOM) post-ISA 95 adoption, leading to more successful project implementations and industry-wide solutions. Practical applications and examples demonstrate the significant efficiencies and cost reductions realized through the standardized framework provided by ISA 95.