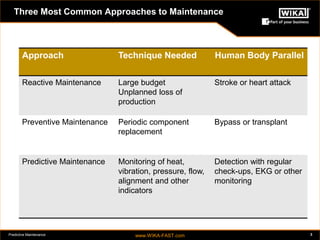

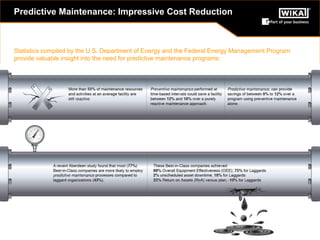

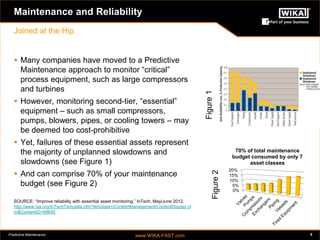

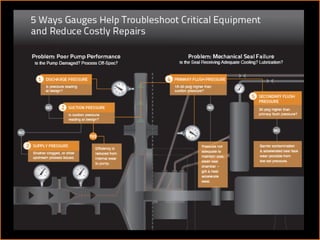

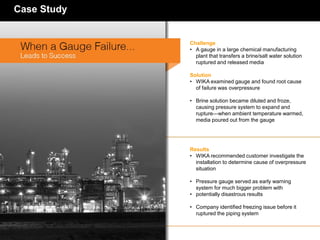

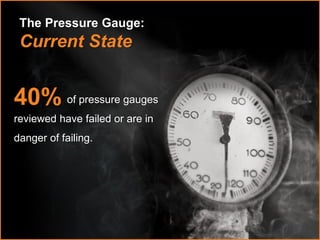

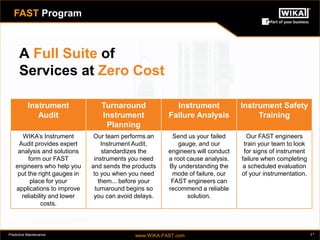

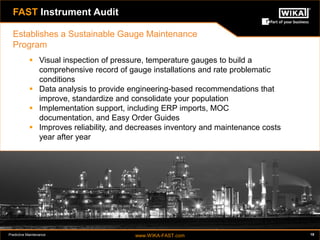

Predictive maintenance is crucial for maintaining a company's essential assets, helping to reduce unplanned downtime and associated costs. Implementing early warning systems through monitoring techniques and the use of low-cost gauges can identify potential issues before they escalate into significant problems. WIKA offers comprehensive audit services to optimize instrumentation, improve reliability, and lower maintenance costs.