Embed presentation

Downloaded 178 times

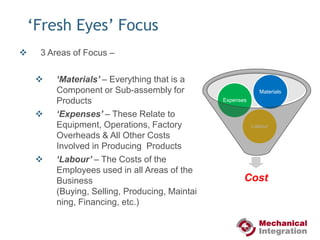

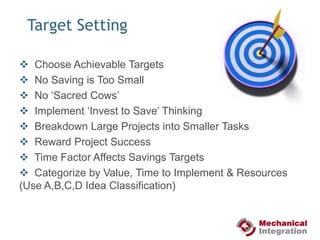

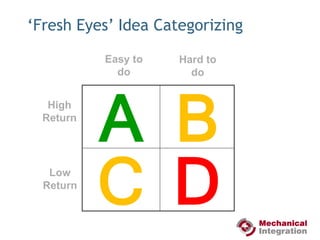

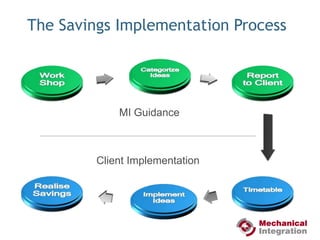

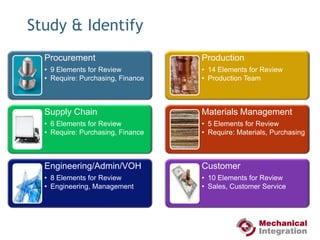

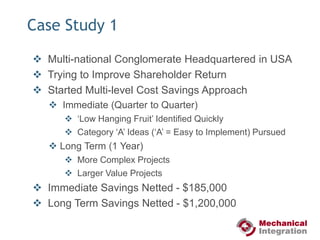

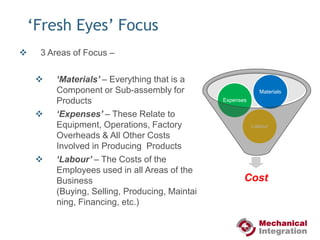

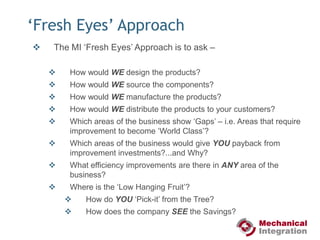

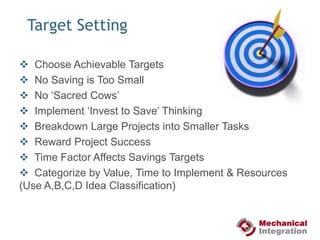

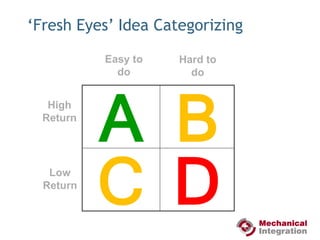

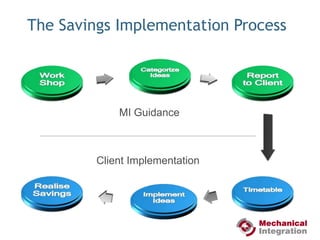

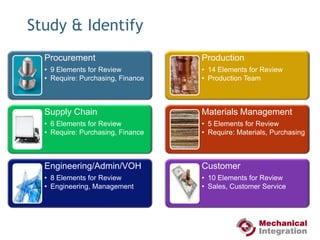

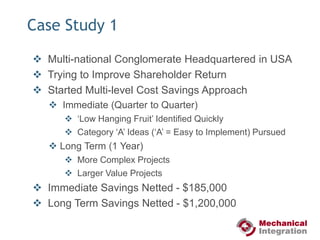

This document discusses cost savings services provided by Mechanical Integration. It was established in 2008 in the US and expanded to the UK and France in 2010. It helps companies eliminate waste, improve efficiency, and create a "savings culture" to prepare for the future. MI takes a "fresh eyes" approach, examining how a company designs, sources, manufactures, and distributes products. It focuses on materials, expenses, and labor costs. MI works with clients to set achievable savings targets, categorize ideas, implement solutions, and realize ongoing savings. Case studies show clients achieving immediate savings of $185,000 and $1.2 million, as well as long term savings of €703,150 and €48,103