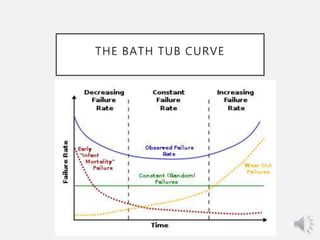

Maintenance management involves planning and coordinating resources to ensure industrial equipment operates effectively at specified availability levels. It aims to minimize downtime and production losses through planned repair and preventative maintenance. There are different types of maintenance systems like corrective, preventative, and predictive maintenance. The bathtub curve model describes failure rates over equipment lifespan from initial high failure through useful life of constant rate to increasing wear out failures. Key activities involve scheduling maintenance, repairs, inspections, budgeting, and developing maintenance procedures, records, and staff training.