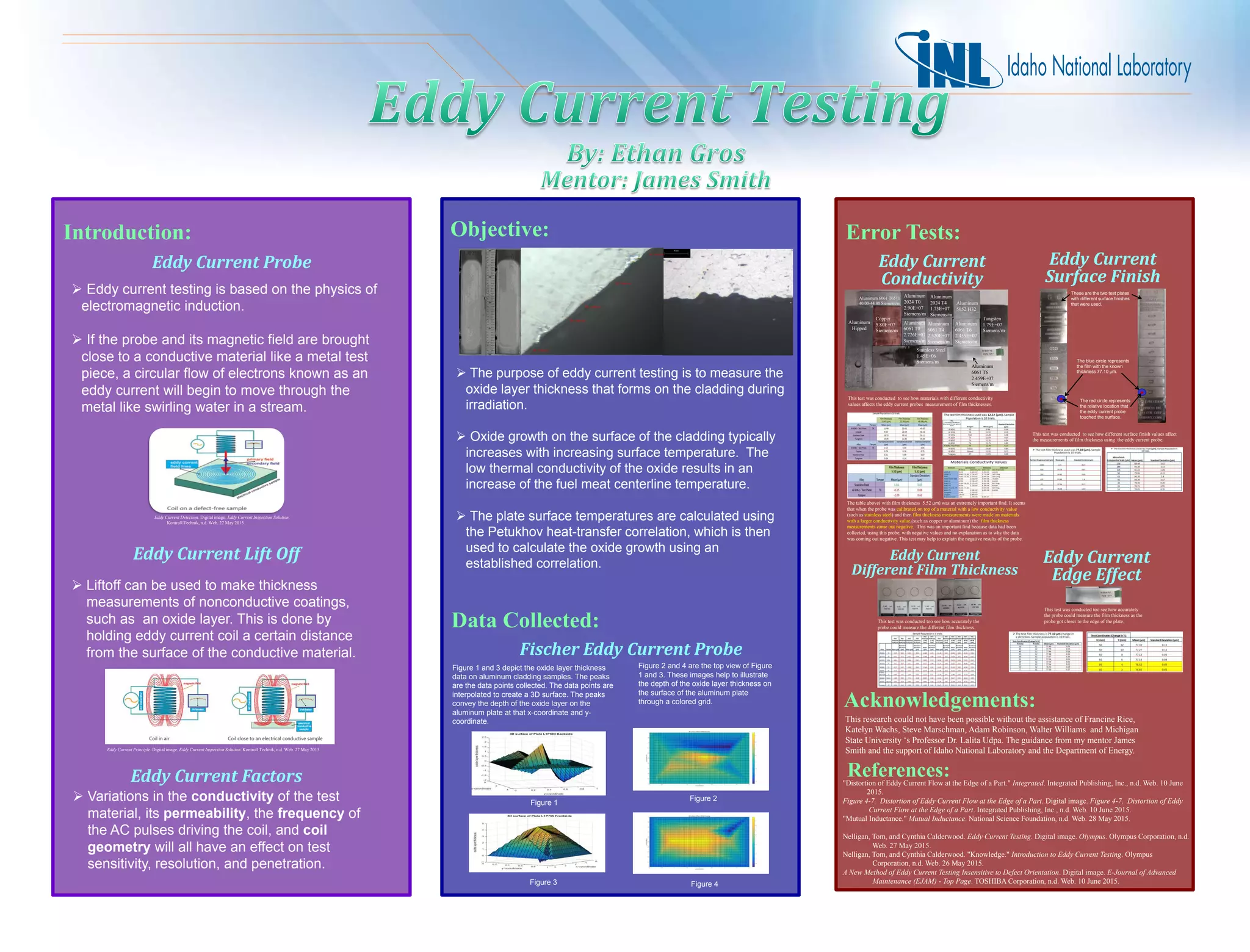

Variations in material properties like conductivity and permeability, as well as testing parameters like frequency and coil geometry, impact eddy current testing sensitivity, resolution, and penetration depth. Eddy current testing works by inducing circular eddy currents in conductive materials using a probe's magnetic field. Liftoff measurements determine thickness of nonconductive coatings on conductive substrates by holding the probe a set distance from the surface. Oxide layer growth on nuclear fuel cladding is measured via eddy current testing, with increased temperature leading to thicker oxides that raise fuel centerline temperatures.