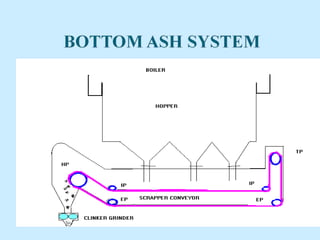

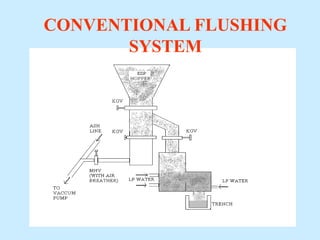

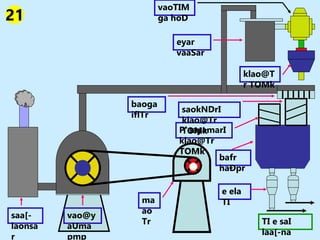

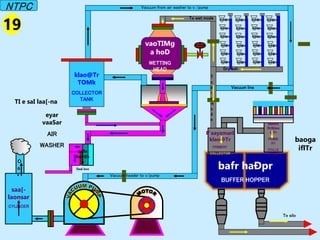

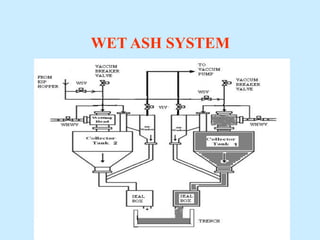

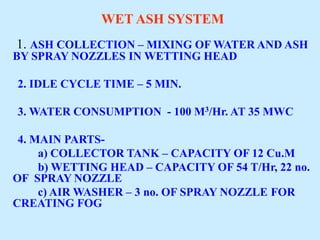

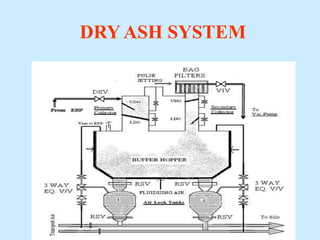

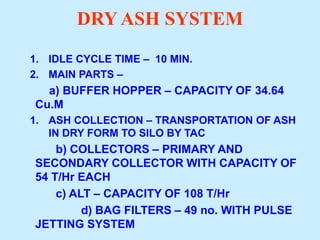

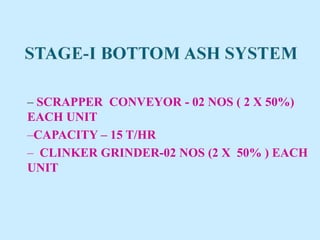

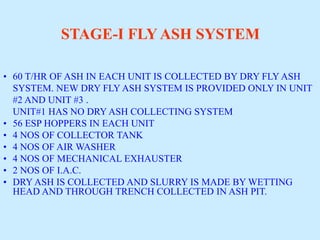

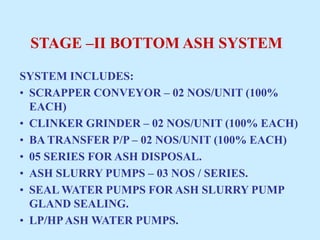

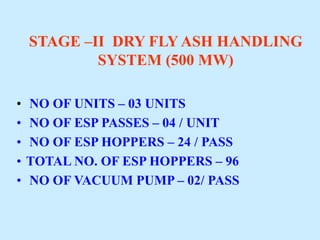

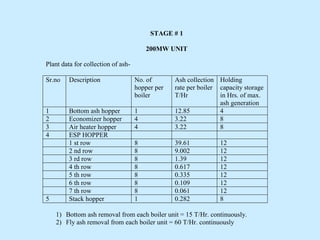

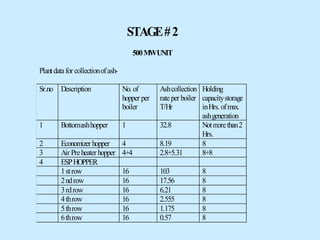

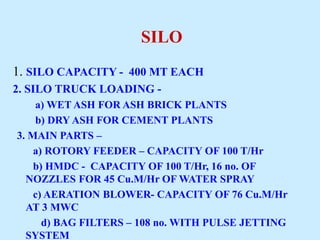

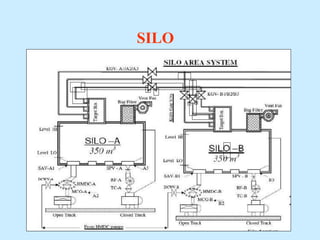

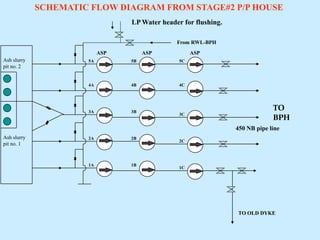

The document describes the ash handling system of a power plant. It collects ash through bottom ash, fly ash, and wet ash systems. Ash is then transported through slurry pipelines and disposed of. The system includes wetting heads, collectors, pumps, and silos for storage. Challenges include equipment corrosion, vacuum leaks, and limited ash utilization.