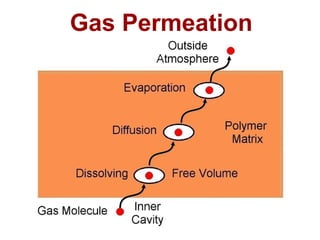

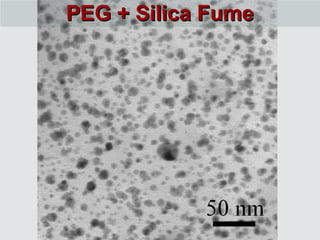

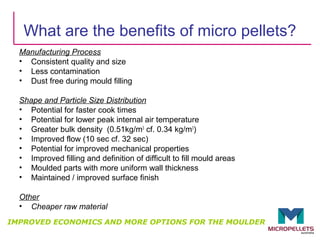

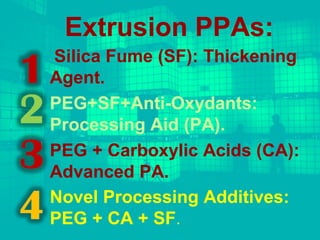

The document discusses using silica fume and polyethylene glycol (PEG) to enhance the sintering of linear low-density polyethylene (LLDPE) powders in the rotomolding process. It presents experimental results showing that adding silica fume and PEG improves the free-flow properties of LLDPE powders and reduces bubbles in molded parts. The additions help dissolve bubbles by increasing the gas permeability of the polymer melt. The document concludes that silica fume acts as a free-flow agent while PEG combined with silica fume acts as a densification and processing aid for rotomolding LLDPE powders.