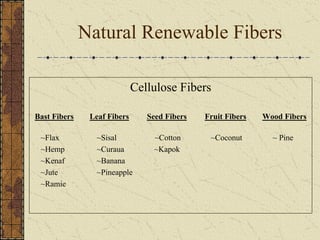

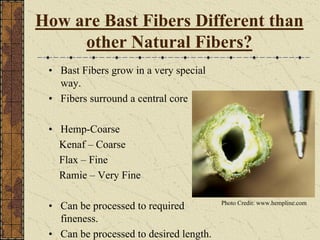

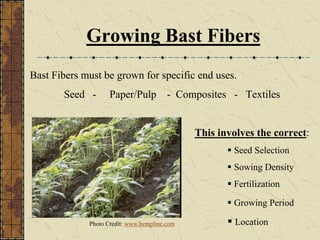

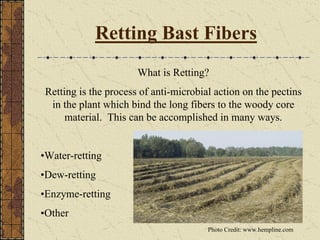

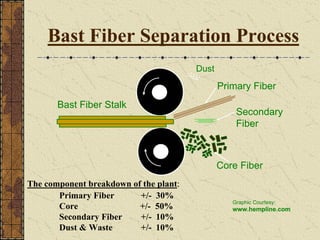

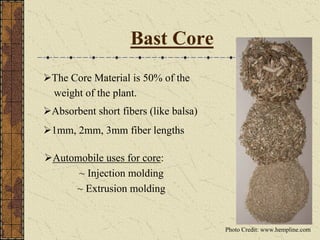

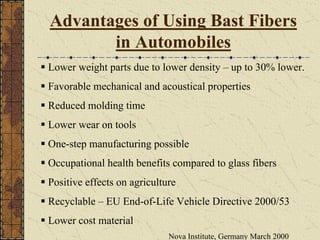

This document discusses natural bast fibers which can be used as an alternative to petrochemical fibers in automotive composites. Bast fibers include flax, hemp, kenaf, and ramie, which are renewable crops that provide long, strong fibers. The document outlines the growing, harvesting, and processing steps to separate the bast fibers from the plant core. It highlights advantages of bast fibers such as lower cost, weight reduction, and environmental benefits compared to fibers like fiberglass. While bast fibers have potential, investment is needed in domestic farming and processing facilities to ensure an adequate supply for the automotive industry.