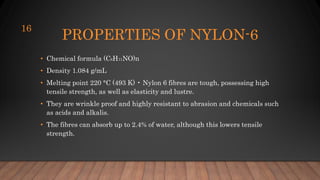

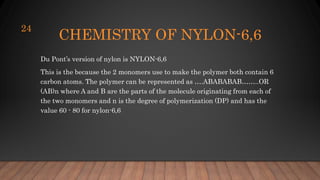

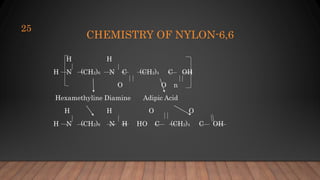

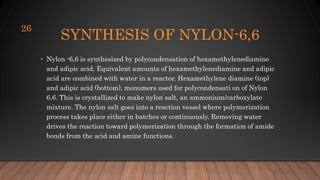

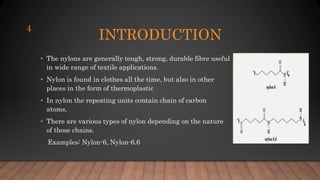

Nylon is a synthetic polymer first produced in 1935. There are various types of nylon fibers depending on their chemical structure, including nylon 6 and nylon 6,6. Nylon 6 is produced through ring-opening polymerization of caprolactam, while nylon 6,6 is synthesized through polycondensation of hexamethylenediamine and adipic acid. Both nylon 6 and nylon 6,6 fibers are strong, durable, and resistant to chemicals and abrasion. Common applications of nylon fibers include carpets, clothing like socks and lingerie, and waterproof materials.

![NAMES OF NYLON-6

IUPAC name

Poly(azepan-2-one); poly(hexano-6- lactam)

Systematic IUPAC name Poly[azanediyl(1-oxohexane-1,6-diyl)]

Other names

Polycaprolactam, polyamide 6, PA6, polyε-caproamide, Perlon, Dederon,

Capron, Ultramid, Akulon, Nylatron, Kapron, Alphalon, Tarnamid, Akromid,

Frianyl, Schulamid, Durethan, Technyl, Nyorbits ,Winmark Polymers

Identifiers CAS Number 25038

15](https://image.slidesharecdn.com/nylonfiberpresentation-210805160659/85/presentation-on-Nylon-Fiber-15-320.jpg)