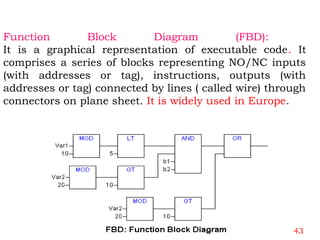

The document provides an overview of Programmable Logic Controllers (PLCs), detailing their definitions, advantages, and components. It emphasizes the shift from traditional relay systems to PLCs, highlighting benefits such as reduced wiring, faster processing times, and enhanced flexibility and reliability. Additionally, it outlines various types of PLCs, programming languages used, and challenges faced in their implementation.