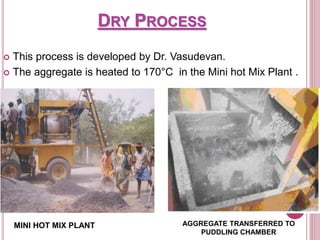

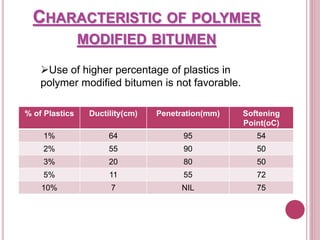

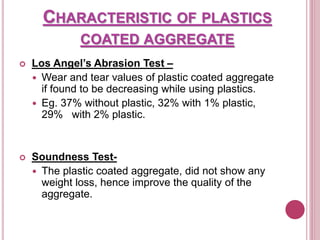

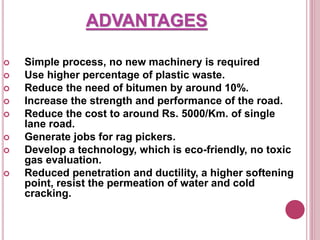

The document discusses the utilization of waste plastic in road construction. It describes how plastic waste like carry bags and bottles can be collected, cleaned, shredded and mixed with hot bitumen to form a coating over aggregates. This coated mixture is then laid on the road like a normal tar road. The dry process involves heating aggregates to 170°C and mixing shredded plastic waste before adding hot bitumen. Using plastic waste in roads can increase strength, reduce costs, and help dispose of plastic waste in an environmentally friendly manner. However, there are also disadvantages like toxic chemicals leaching during the cleaning and road laying processes.