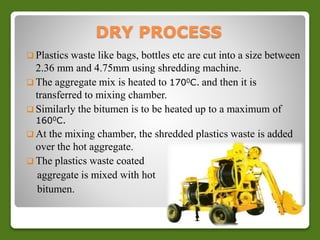

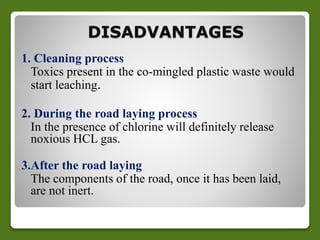

The document discusses the use of waste plastics in road pavement construction to address issues related to plastic waste disposal and road quality. It outlines the methods of mixing plastic waste with bitumen, advantages such as increased durability and reduced maintenance costs, and possible disadvantages including toxic emissions during the laying process. Successful implementations in Bangalore highlight the potential of this innovative technology to improve road conditions while benefiting the environment.