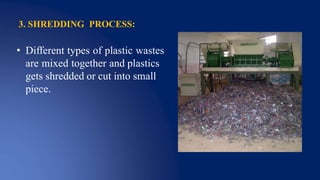

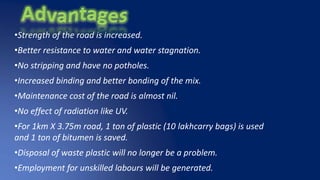

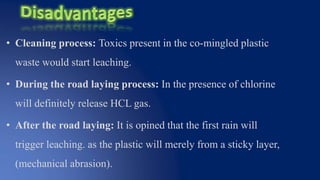

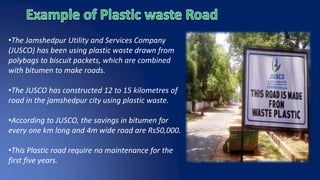

The document discusses the construction of plastic roads, which utilize shredded waste plastic mixed with bitumen to enhance road durability and performance. It outlines the benefits of using waste plastics for road construction, such as reducing environmental pollution and eliminating disposal issues, while detailing the construction process. The initiative not only strengthens the road infrastructure but also has potential economic benefits through job creation and cost savings in materials.