UNIT-5.pptx

- 2. Definition • A gas molecule at room temperature consists of two or more atoms. • When such a gas is heated to a high temperature of order 2000˚C or so, the molecule separates out as atoms. • If the temperature is raised to 3000˚C, the electrons from some of the atoms dissociate and the gas becomes ionized consisting of ions and electrons. • This state of gas is known as “PLASMA”.

- 3. • Thus, Plasma is glowing , ionized gas that results from heating of a material to extremely high temperature. • Plasma gas is neutral. It consists of equal amount of ions and electrons. • Thus the plasma gas becomes electrically conductive as well as responsive to magnetism. • Because of such behaviour, plasma is known as a fourth state of matter.

- 4. • The temperature of plasma can be of the order 33,000˚C. • When such a high temperature source reacts with work material, the work material melts out and may even vaporize, and finally is cut into pieces. • Many materials like Al, stainless steel.. Have good thermal conductivity, large heat capacity, and good oxidation resistance. As a result they cannot be cut by conventional technique like oxy-fuel cutting. But these materials can be easily cut by Plasma Arc Cutting (PAC).

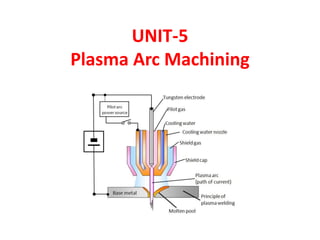

- 5. Plasma Arc Machining 2% thoriated tungsten

- 6. PAC System • PAC system uses DC power source. • PAC system operate on either 1. Non- Transferred arc mode or 2. Transferred arc mode

- 7. PAC System

- 8. Elements of PAC system • Power source • Gas supply • Cooling water system • Plasma torch.

- 9. DC power source Can deliver up to 1000A at about 200V

- 10. Gas supply system • The gases used should be inert(non- oxidising) • High thermal conductivity, to transfer more heat. • Generally used plasma gas is Nitrogen. • Shielding Gases: Carbon dioxide & Argon- Hydrogen….)

- 11. Types of Plasma torches • There are mainly two types of torches 1. Non- transferred arc torches 2. Transferred arc torches a. Turbulent mode flame torch b. Laminar mode flame torch c. High power torches

- 12. Plasma Torch

- 13. 1. Non- Transferred arc torch Useful for spraying, ceramic working & chemical synthesis

- 14. Types of Transferred arc Plasma torches 1. Transferred arc torches a. Turbulent mode flame torch b. Laminar mode flame torch

- 15. b. Laminar mode flame has low velocity, lengths as long as 1m flame is emitted It is used for spheroidizing & melting ceramics. High carbon steels Types of Transferred arc Plasma torches

- 16. Types of Transferred arc Plasma torches a. Cutting torches b. Welding torches c. Micro torches or needle torches

- 17. 2. Transferred arc torch a. Cutting torches i. Air plasma flow torch ii. Oxygen injected torch iii. Dual flow torch iv. Multiport nozzle torch v. Water injected torch

- 18. Air plasma flow torch •Tapered machined surface •Double arcing. •Zirconium electrode life 2hr ( resistance to oxidation)

- 19. Dual flow torch •Plasma gas: nitrogen •Shielding gas: oxygen, co2,argon – hydrogen etc. •Sharp corners on the top side of cutting edges

- 20. Oxygen injected torch • To avoid oxidation of electrode or life of the electrode. • Nitrogen is the plasma gas. oxygen is injected down stream of the electrode. • MRR • Poor squareness of the cut edges.

- 21. Multiport torch

- 22. Water injected torch •Water pressure 1.2MPa •Plasma gas Nitrogen at 1MPa •To avoid double arcing •Swirl motion of the water results in one edge being cut is straight

- 24. General considerations • Large current requires large orifice diameter cathode, orifice length & electrode gap. • For larger arc voltage increase the angle of taper at the cathode tip. • For avoiding turbulence the edges of construction are rounded off & smaller cathode diameters are used. • Non- transferred arc modes use long throat lengths, while for transferred arc mode , the minimum arc lengths are used. • High quality Insulation is used & the insulator portion should be away from the arc zone.

- 25. Accuracy and surface finish

- 26. Effect of cutting voltage

- 27. Accuracy and surface finish • If the speed is the upper edge of the cut reaches too far. i.e., the kerf is too wide forming a V- shaped c/s. • speed also results in kerf. • The optimum cutting speed is achieved by advancing the torch at a rate of distribution of heat flow from plasma in to material is uniform throughout the thickness of the material.

- 28. Accuracy and surface finish • For example kerf width on a plasma cut in 25mm stainless steel is about 5mm. • A plasma cut in 175mm thick stainless steel produces 30mm kerf width. • Thickness of plate kerf width • Plasma arc cuts are dross free if proper cutting conditions and the appropriate cutting gases are used.

- 29. Accuracy and surface finish “Dross “ is the name given to metal that melts During cutting but adheres to the bottom edge of the cue face.

- 30. Applications • Plasma arc welding • Plasma arc cutting • Plasma arc surfacing • Plasma arc spraying