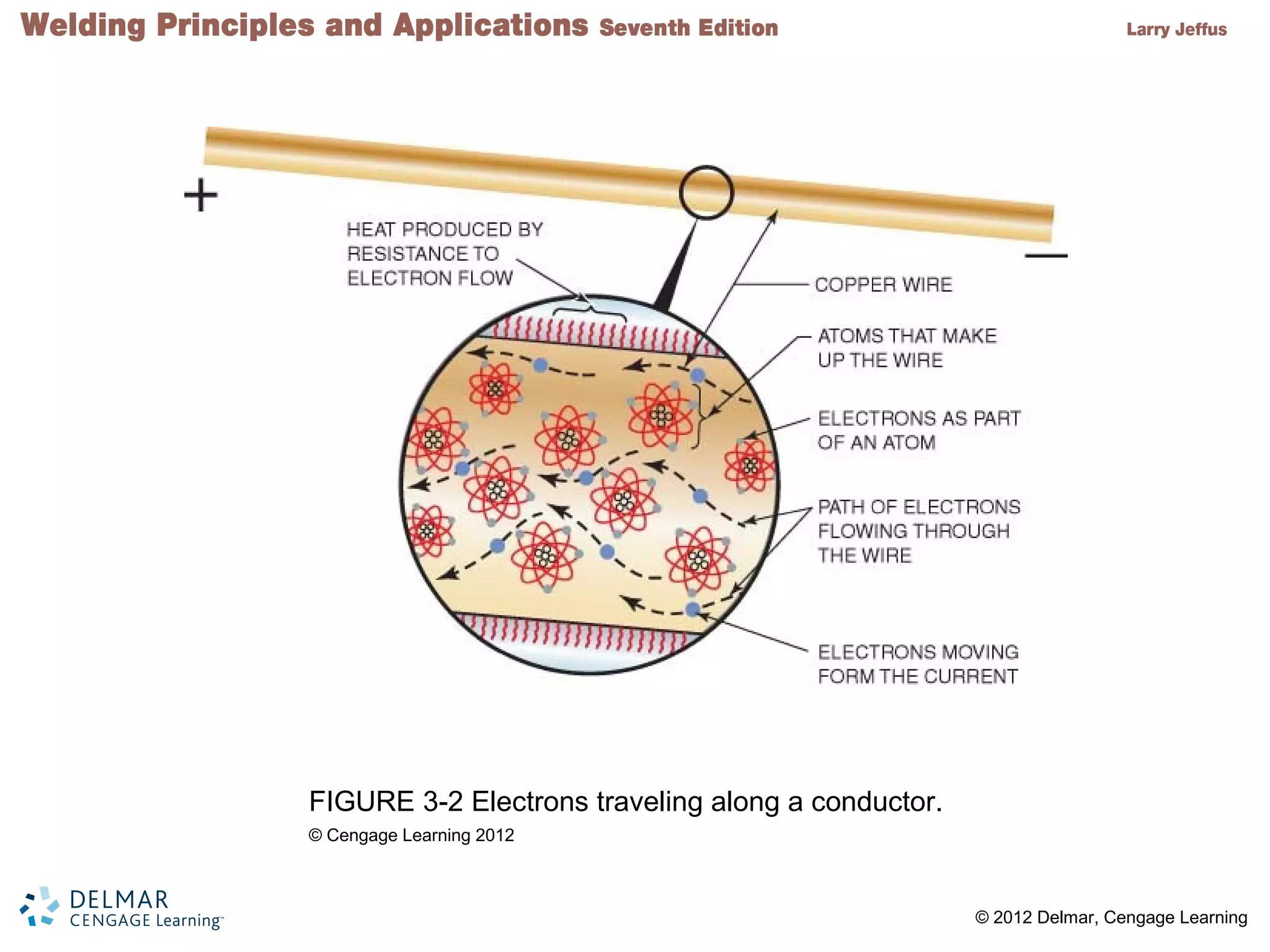

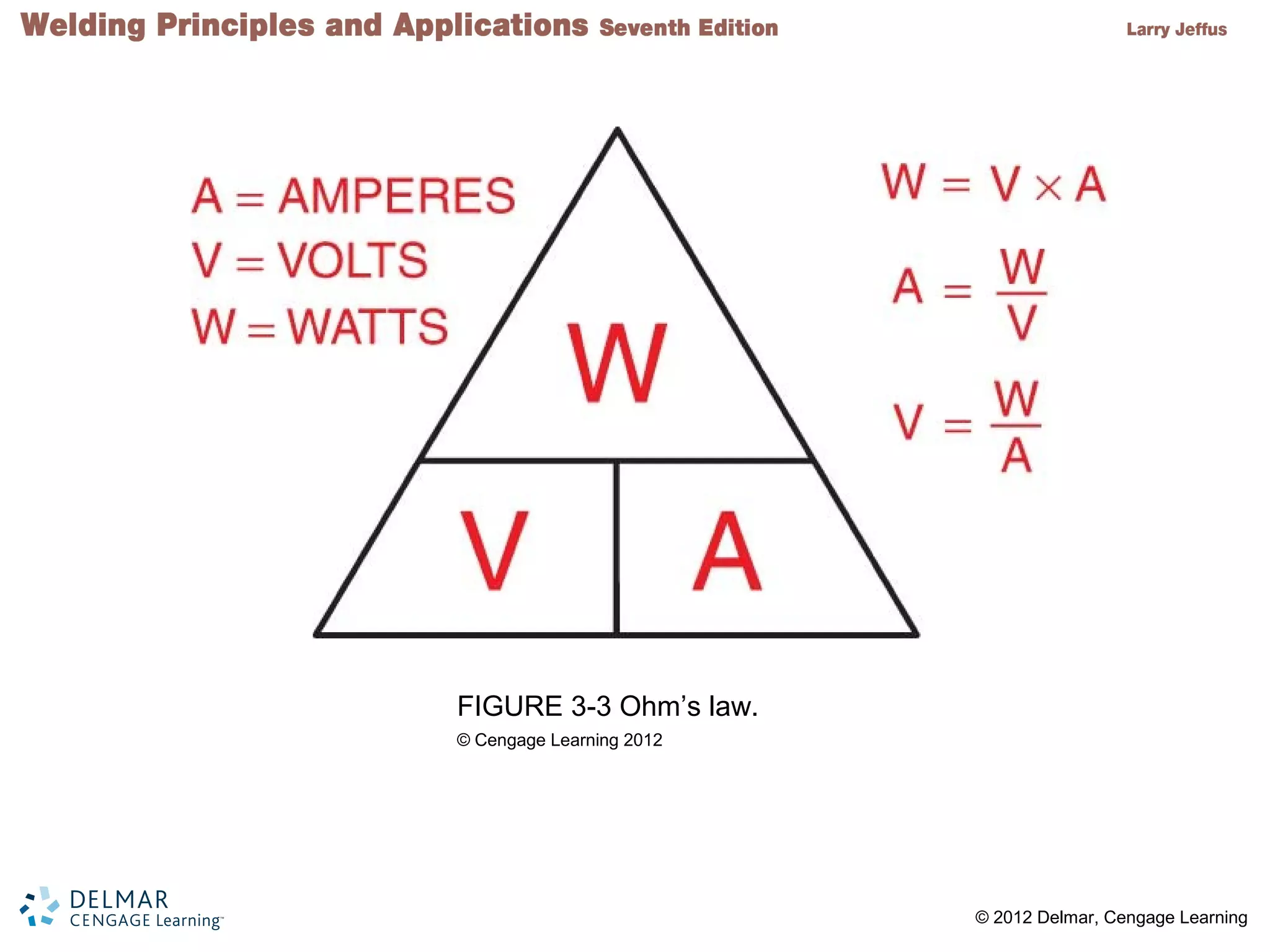

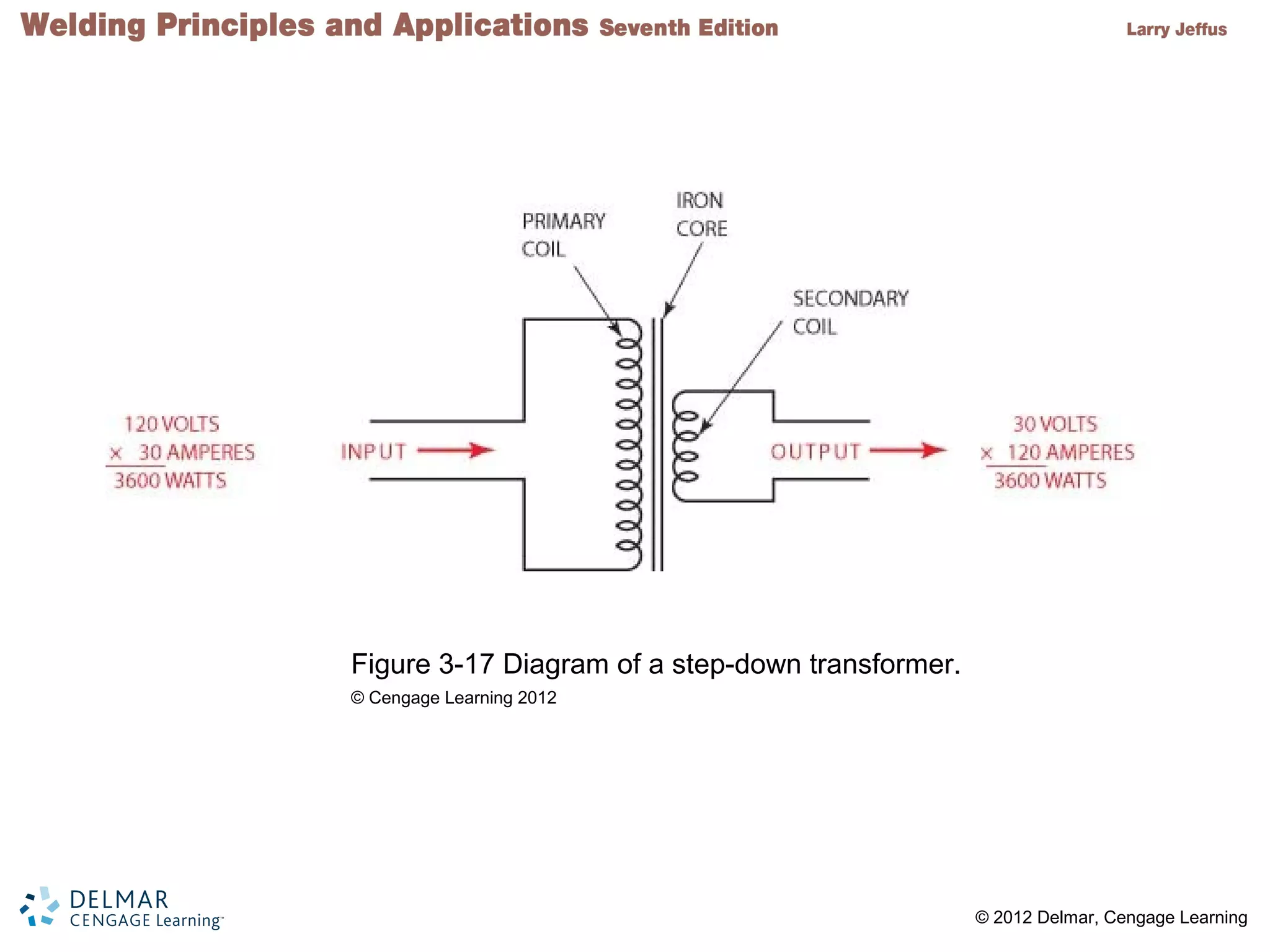

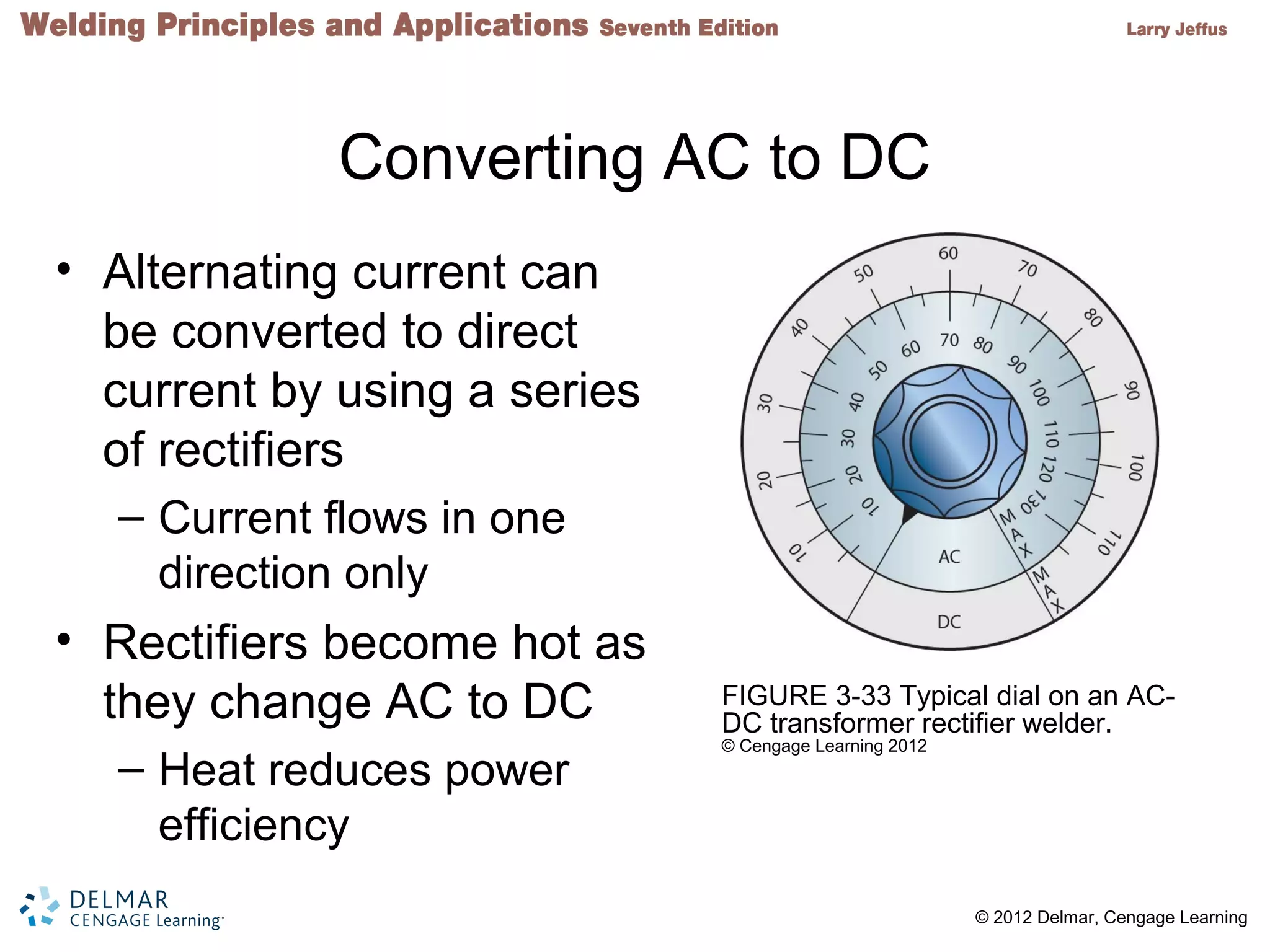

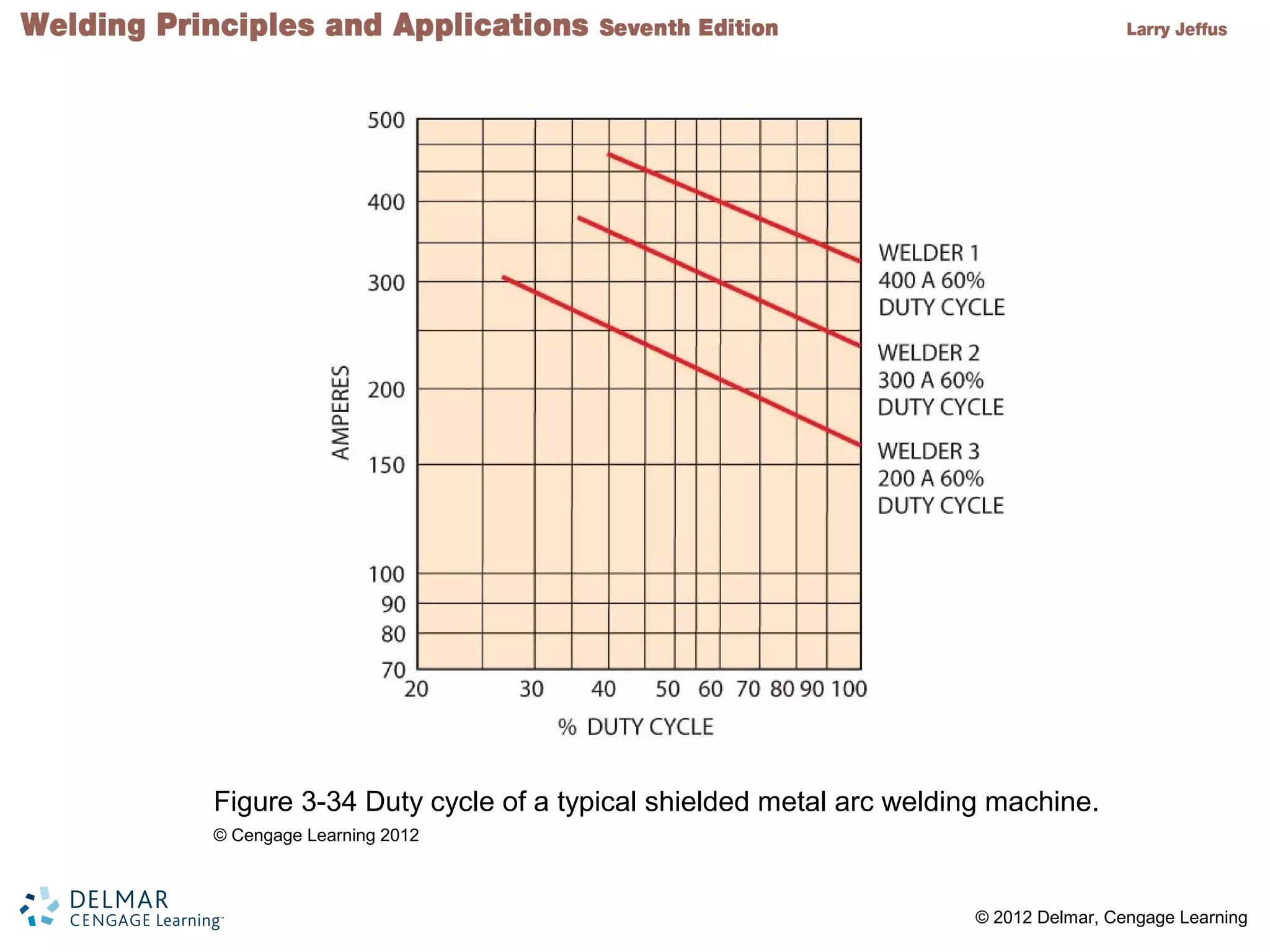

This document outlines the objectives and content covered in a chapter about shielded metal arc welding setup and operation. The key topics covered include: describing the SMAW process and the units used to measure welding current; explaining the types of welding currents and power sources; demonstrating how to determine proper welding cable size and service electrode holders; and discussing important safety considerations for equipment setup and preventing accidents.