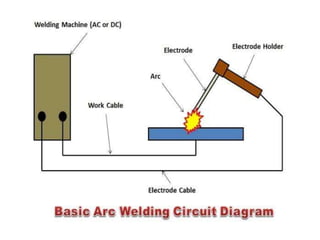

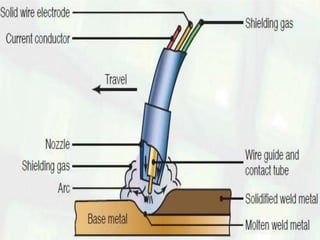

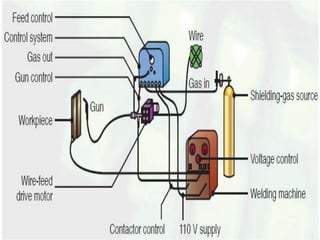

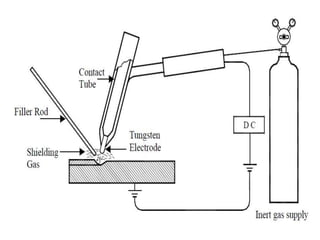

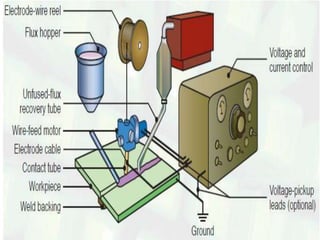

Arc welding is a popular welding method that uses an electric arc to fuse metals, employing various techniques such as Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), and Submerged Arc Welding (SAW). Each type has distinct advantages; for instance, GMAW is economical and easy to automate, while SAW allows for deeper heat penetration and higher productivity. The document outlines specific characteristics, applications, and benefits of each welding technique.