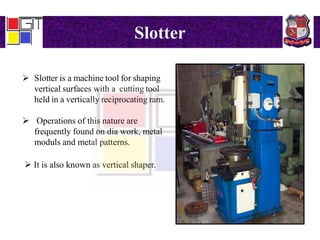

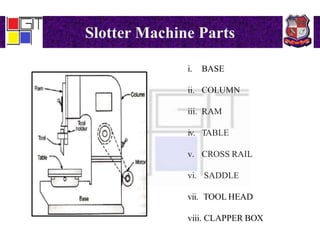

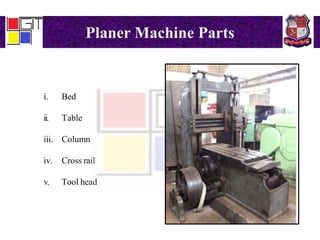

This document provides an overview of planer and slotter machines. It describes that a slotter is a machine tool that uses a vertically reciprocating ram to shape vertical surfaces with a cutting tool. It classifies slotters and describes their drive mechanisms, feed mechanisms, and main parts which include the base, column, ram, table, cross rail, and saddle. It also lists the common operations performed on a slotter like cutting internal grooves. For a planer, it similarly describes the machine, classifies types, and outlines their drive mechanisms, feed mechanisms, main parts, and operations like planing flat surfaces.