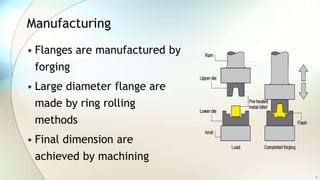

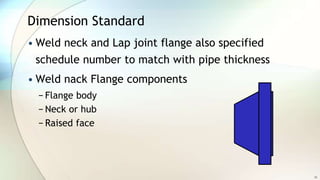

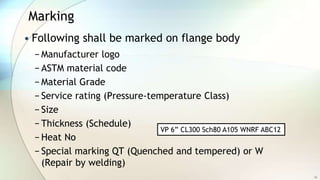

The document outlines the manufacturing processes and quality standards for flanges, including forging, heat treatment, testing methods, and inspection criteria. It specifies the dimensional standards as per ASME codes, categorization by pressure ratings, and necessary markings on the flanges. Additionally, it emphasizes the importance of visual inspection and testing to ensure product quality.