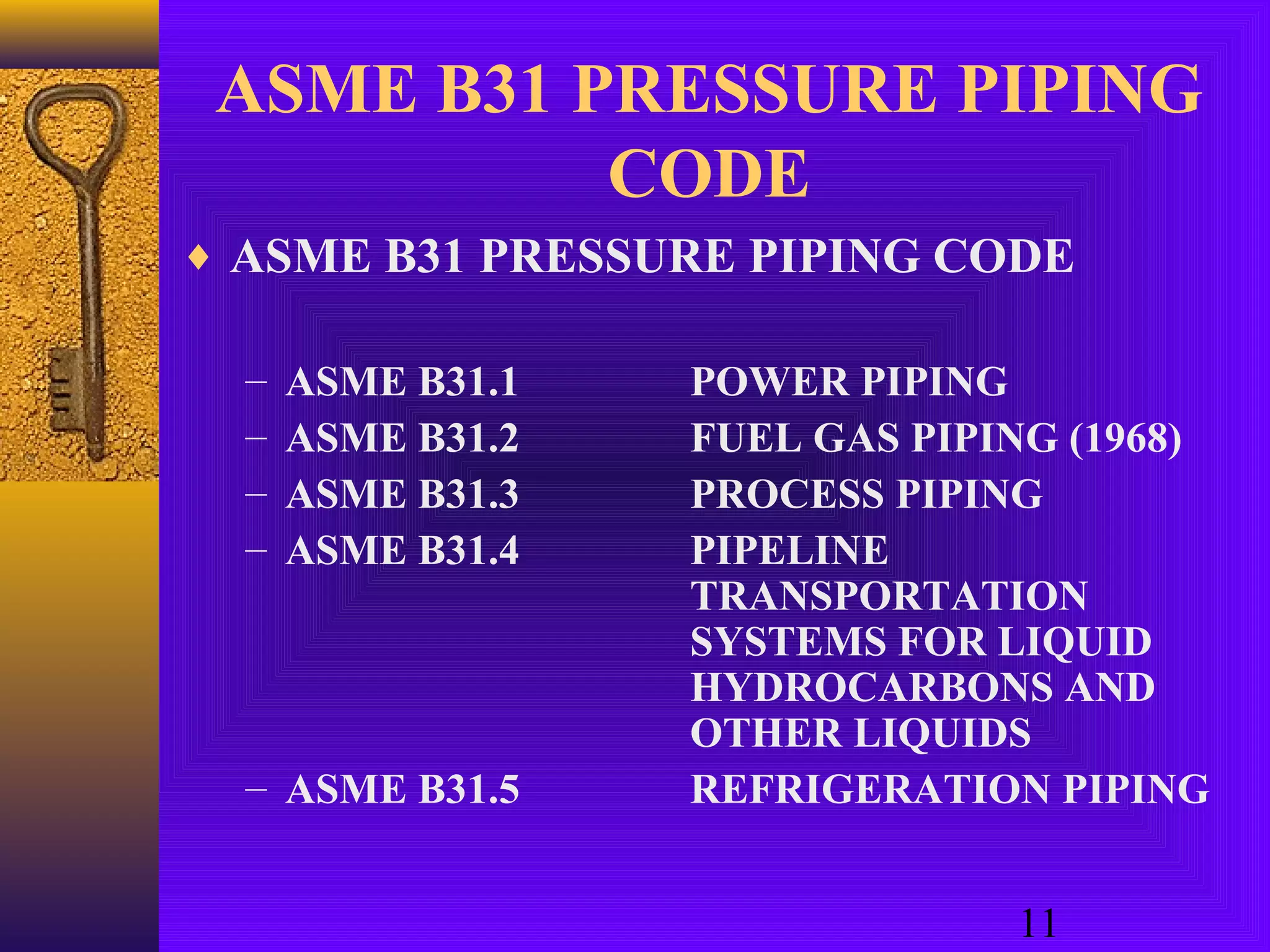

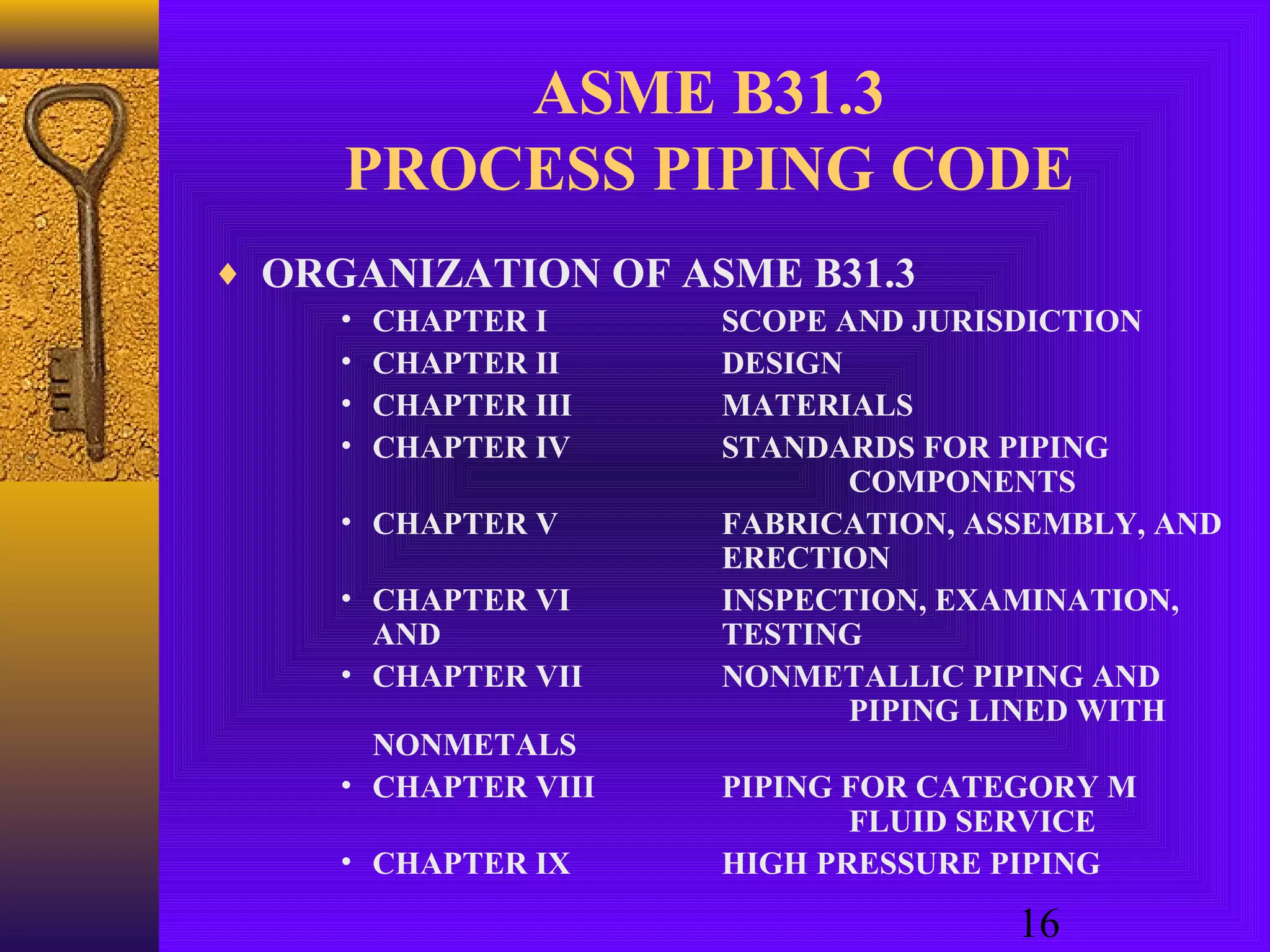

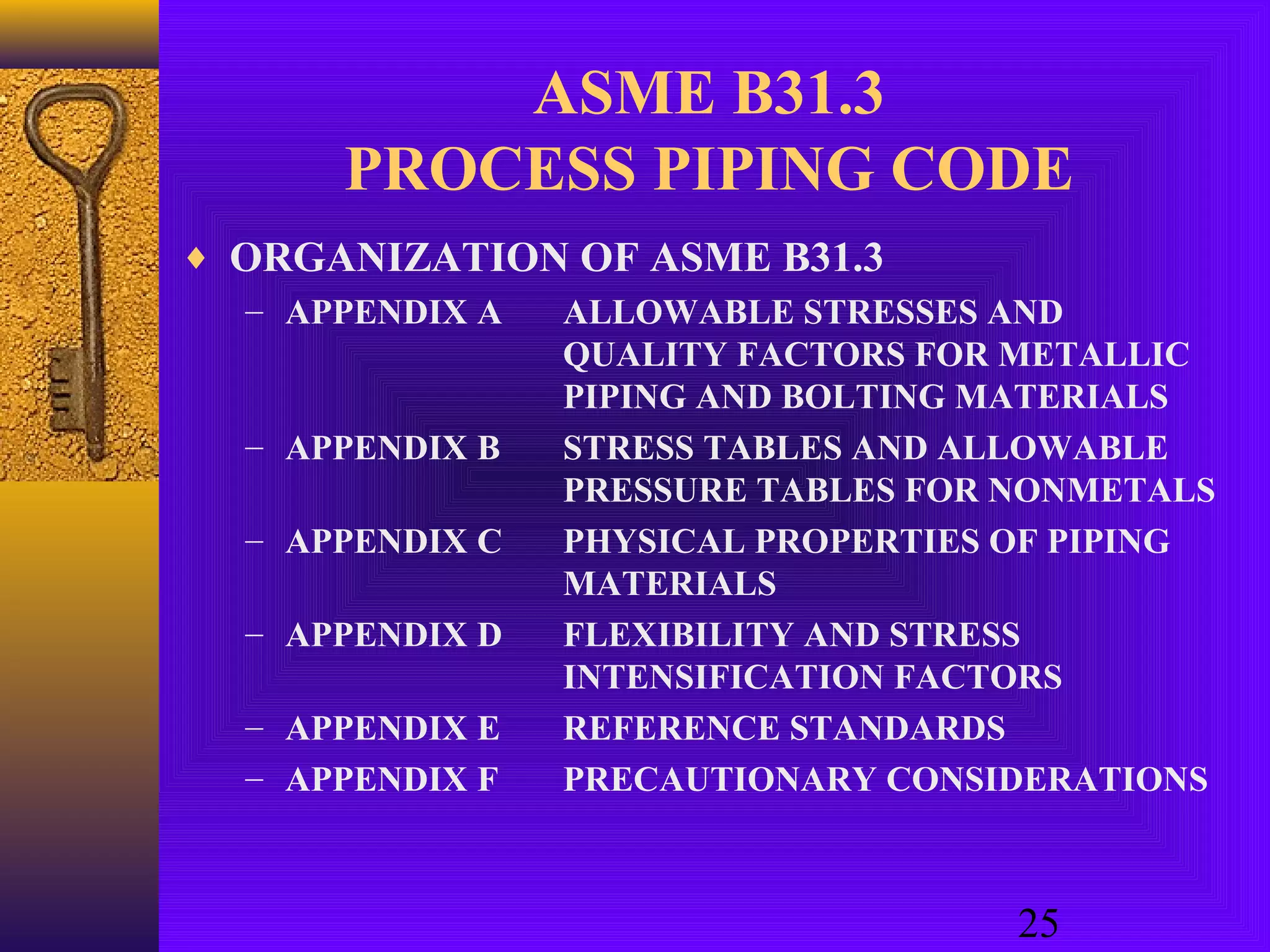

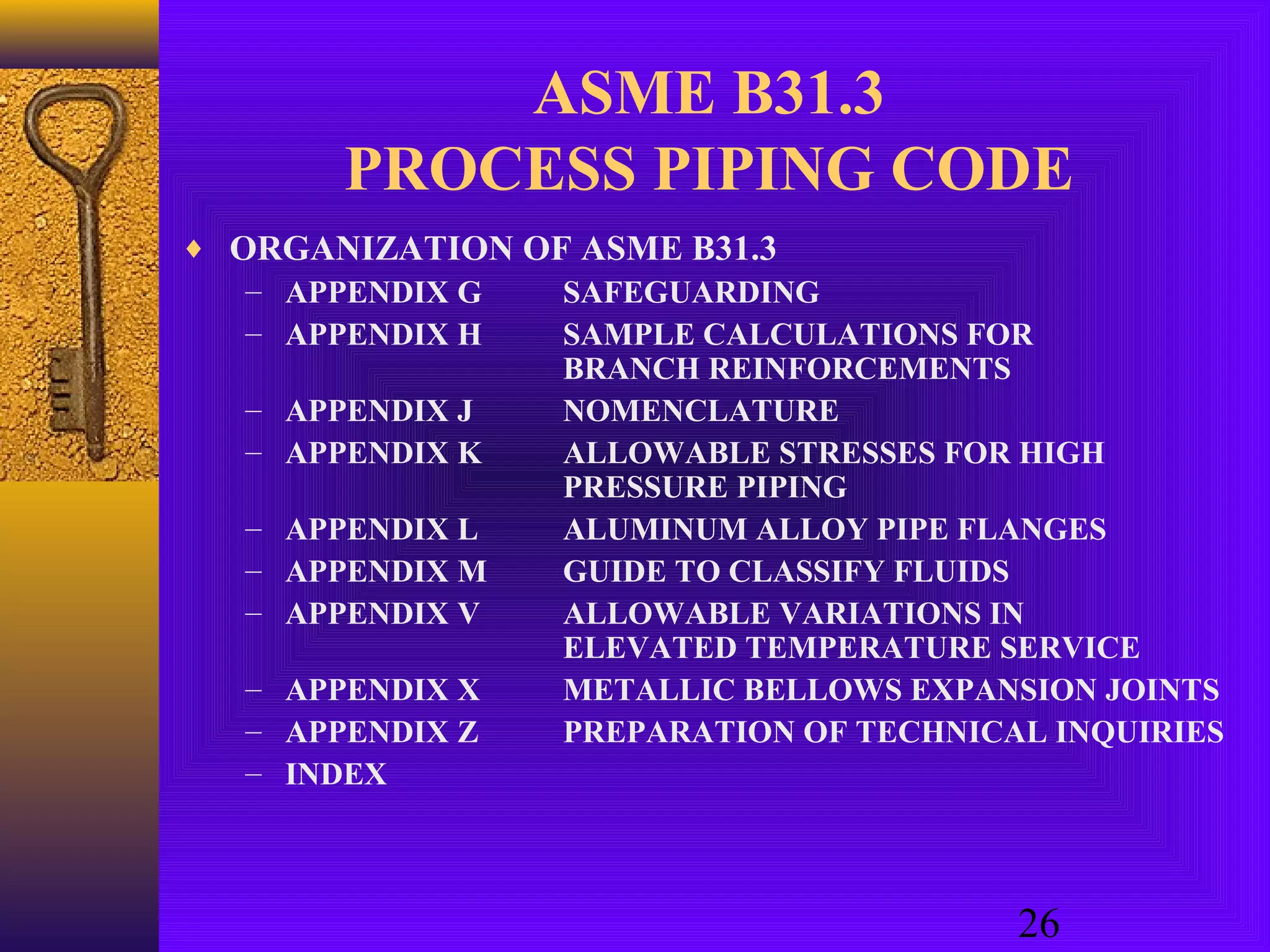

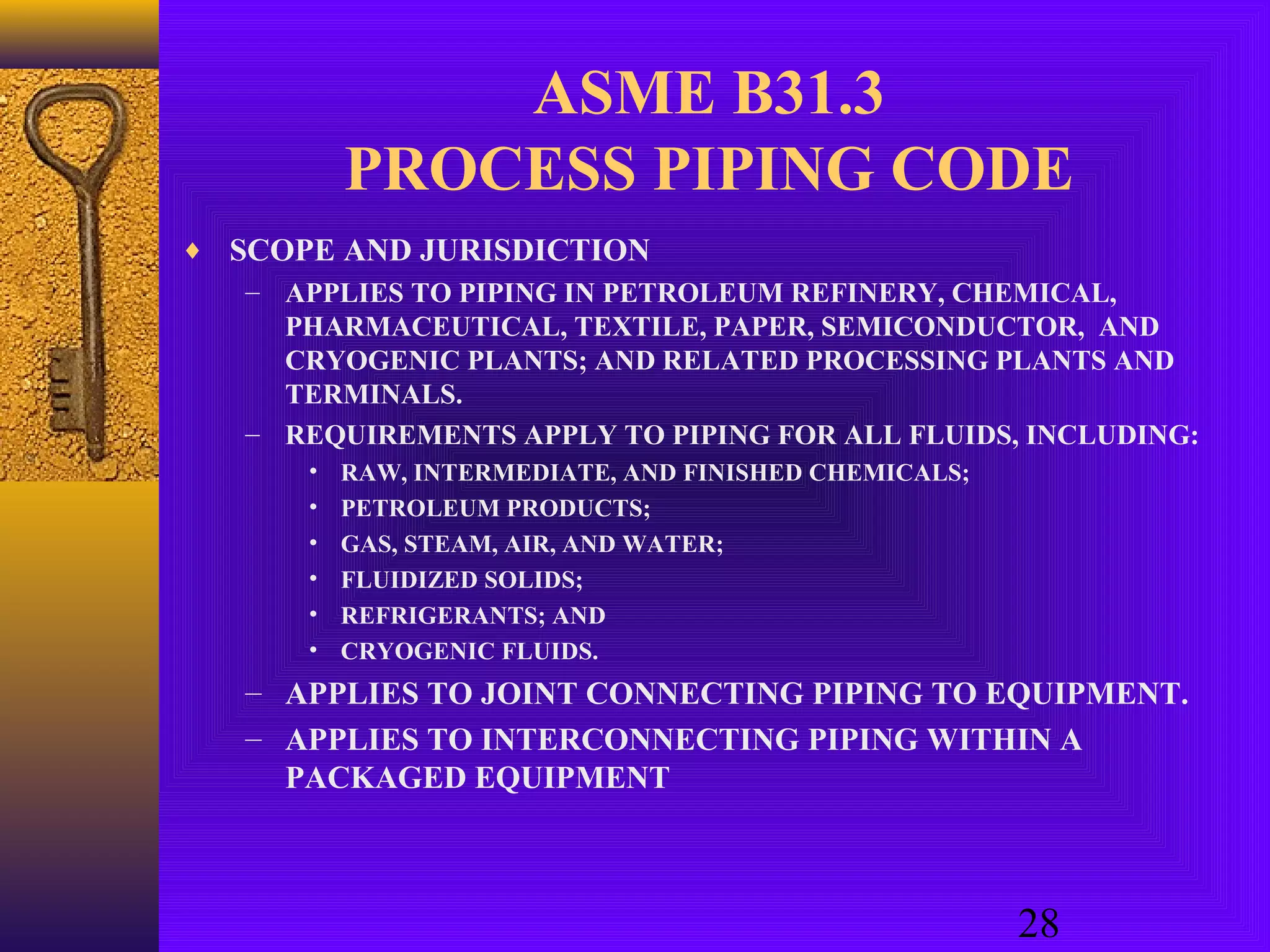

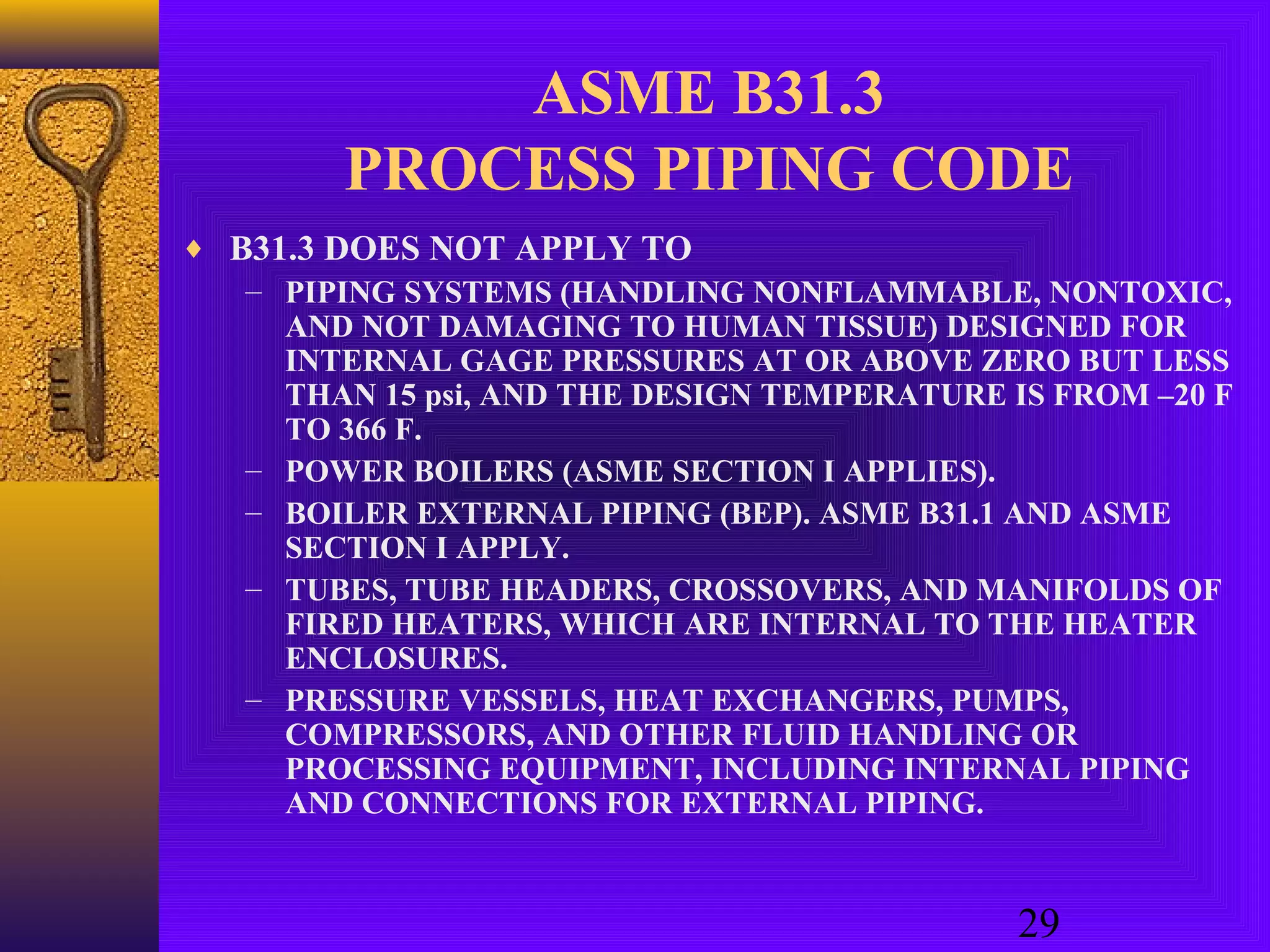

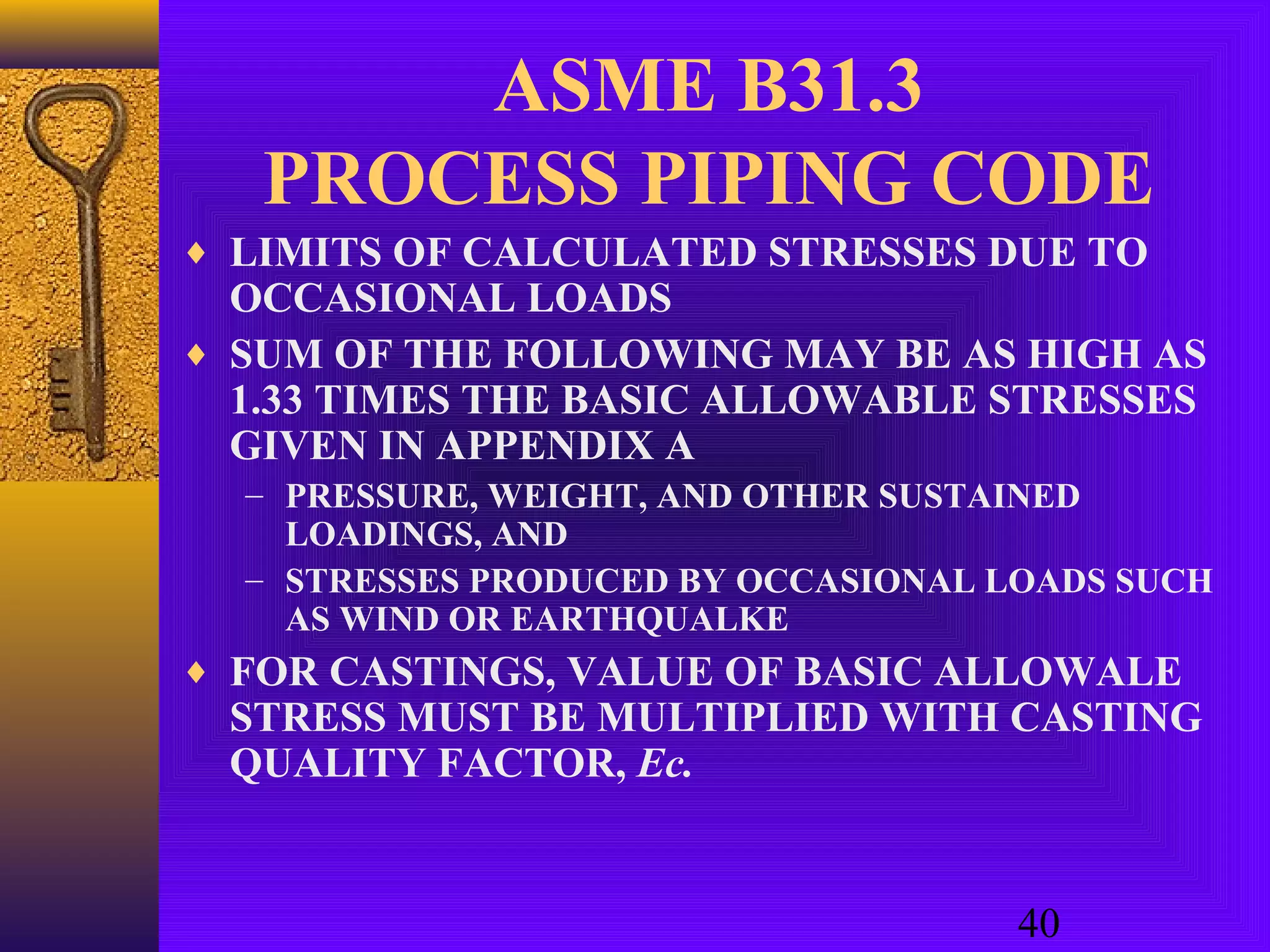

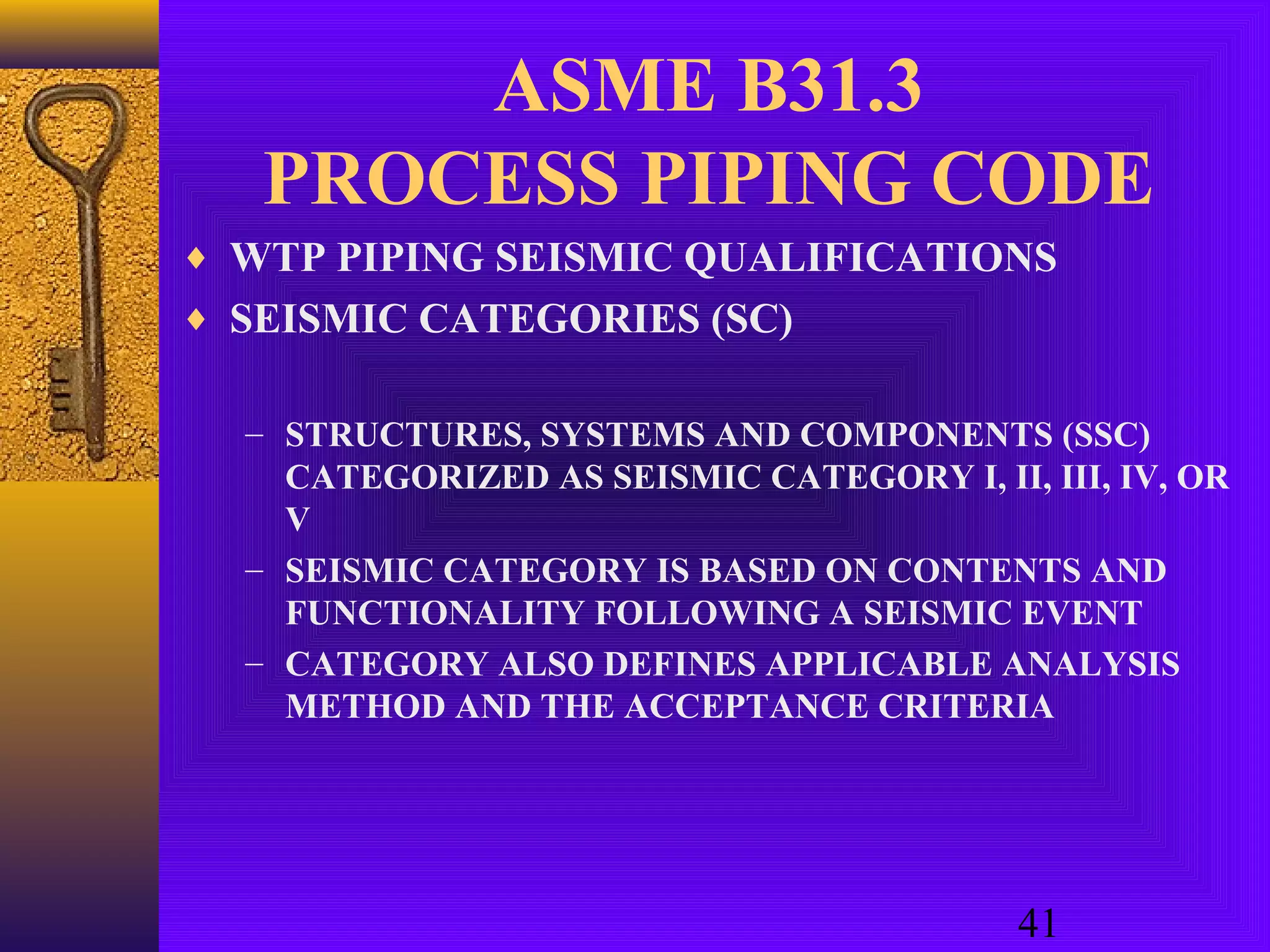

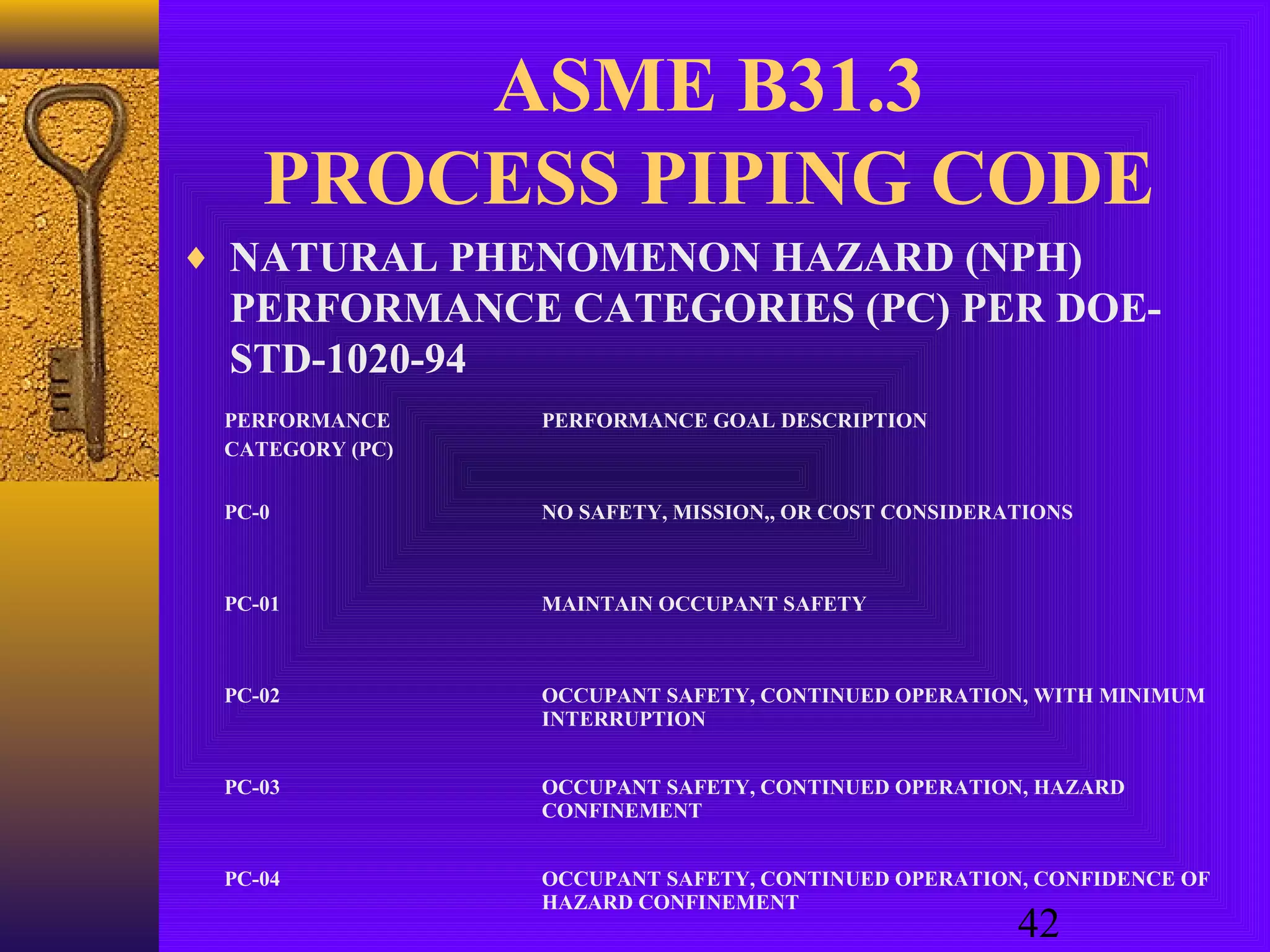

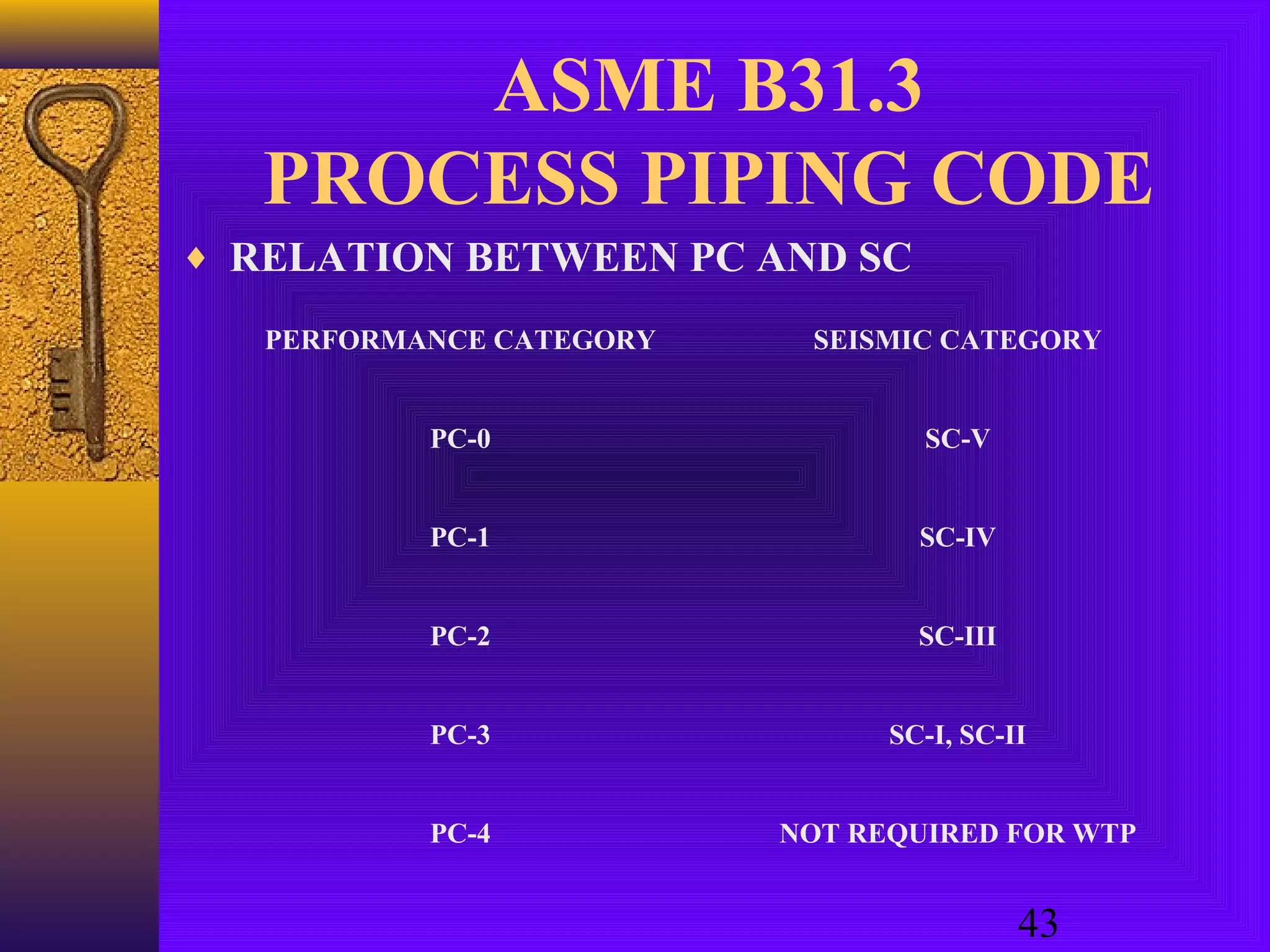

The document provides an overview of the ASME B31.3 Process Piping Code. It discusses the code's philosophy, organization, history, scope, fluid service categories, and application. Key points include that B31.3 applies to process piping systems in chemical, petroleum, and other plants. It covers piping for various fluids and has specific requirements for Category M and high pressure fluid services. The code is organized into chapters that address design, materials, components, fabrication, inspection, and other topics.