The document describes various weld inspection gauges and tool kits. Key details include:

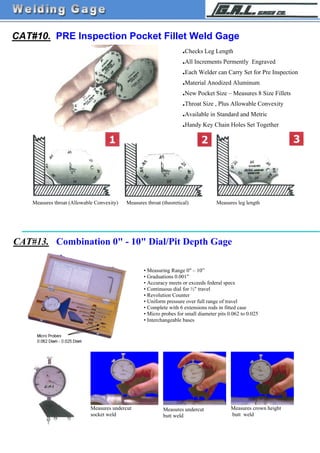

- Pocket and bridge cam gauges measure weld parameters like angle of preparation, excess weld metal, undercut depth, pitting depth, fillet weld throat size, and misalignment.

- Adjustable and automatic weld gauges measure fillet weld throat thickness and leg size.

- Combo gauges measure butt weld height, fillet weld leg and throat size, and angle of preparation.

- Skew-T, socket, and mini fillet gauges check fillet welds on pipes and skewed members.

- Tool kits include essential gauges