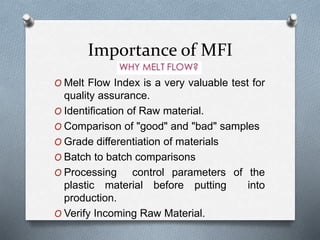

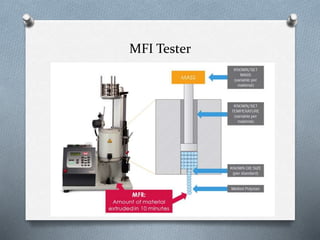

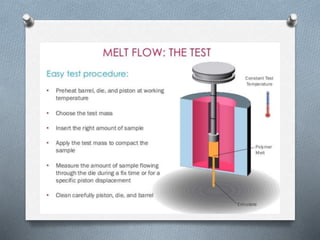

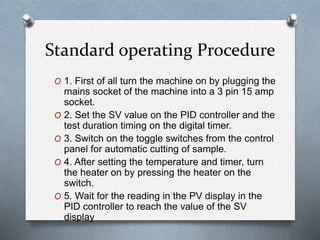

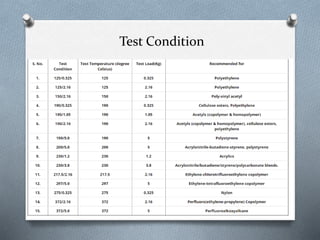

The document outlines the concept and importance of melt flow index (MFI) as a measurement of polymer flow, defining it as grams of polymer that flow through a die in ten minutes under specific test conditions and temperatures. It details the testing procedure, including the necessary equipment, sample preparation, and the steps to accurately measure MFI, highlighting significant test standards, such as ASTM D1238 and ISO 1133. MFI serves as a critical quality assurance tool for material identification, comparison, and processing control in plastic production.