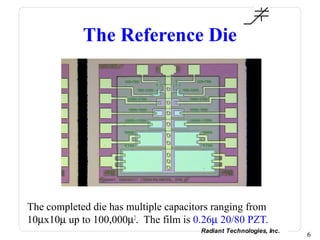

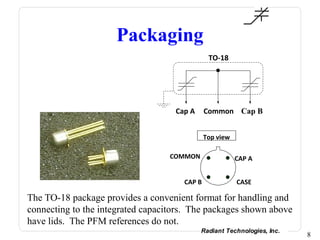

The document describes a reference die containing thin film PZT capacitors that can aid in piezoelectric characterization using an atomic force microscope (AFM). The die has exposed top electrodes and PZT surfaces to allow piezoelectric force microscopy (PFM) characterization. The packaged die is mounted in an AFM to demonstrate PFM techniques like visualizing polarization switching and domain imaging of the PZT film.