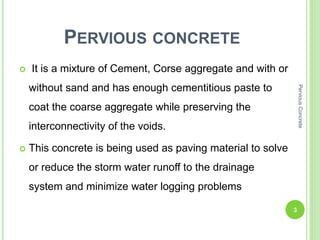

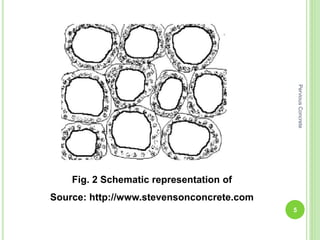

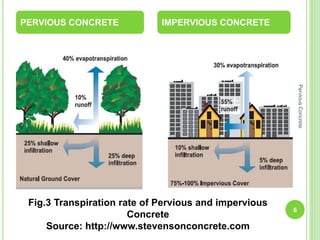

Pervious concrete is a high porosity concrete that allows water to pass through, reducing runoff and aiding groundwater recharge, recognized as a best management practice by the EPA. It comprises cement and coarse aggregates, with applications in sustainable construction to mitigate water logging and enhance drainage. Despite its benefits, issues such as clogging, variability in permeability, and acceptance by municipalities remain challenges.

![Table 1 Physical properties of Cement

Source:[1]

15

PerviousConcrete](https://image.slidesharecdn.com/perviousconcrete-190803034938/85/Pervious-concrete-15-320.jpg)

![Table 2: Typical Pervious Concrete Materials Proportions

Source :[1]

18

PerviousConcrete](https://image.slidesharecdn.com/perviousconcrete-190803034938/85/Pervious-concrete-18-320.jpg)