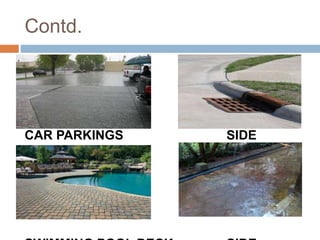

The document discusses pervious cement concrete pavement, which is designed to allow stormwater to infiltrate rather than run off. It can absorb 36,000 mm of water per hour through its porous structure. Pervious pavement is mostly used for low-traffic areas like sidewalks, driveways, and parking lots. The document outlines the materials, properties, design considerations, construction process, maintenance needs, and environmental benefits of pervious cement concrete pavement.