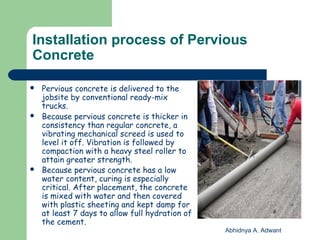

Pervious concrete is an eco-friendly mixture allowing significant water drainage, typically used in pavements like parking lots and sidewalks in California and Washington. It requires a specific installation process with careful curing due to its low water content, providing economic and environmental advantages despite higher initial costs. Limitations include a rough surface unsuitable for heavy traffic roads, indicating a need for further research to enhance usability.