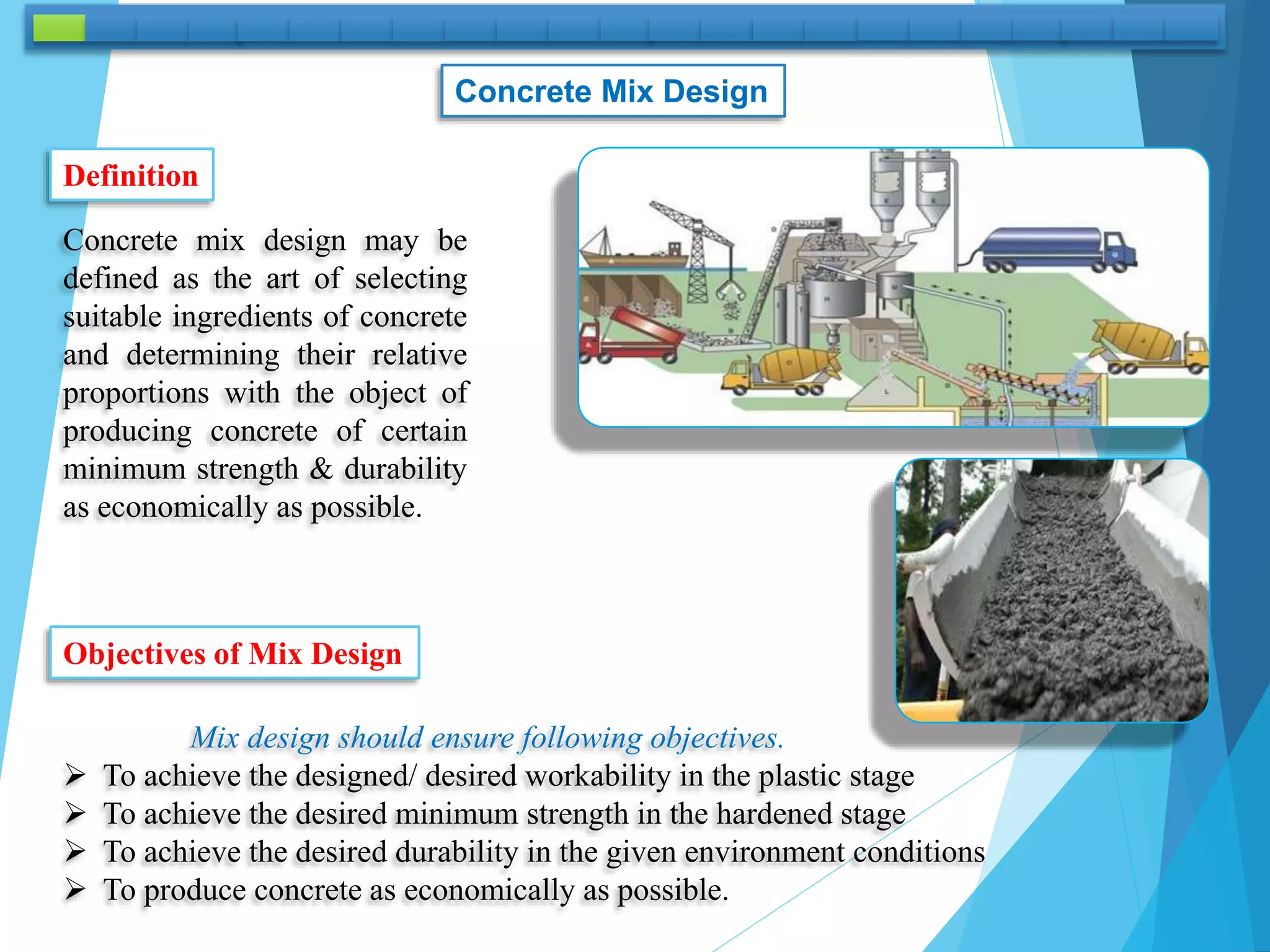

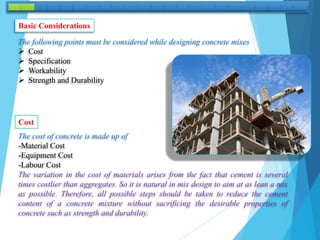

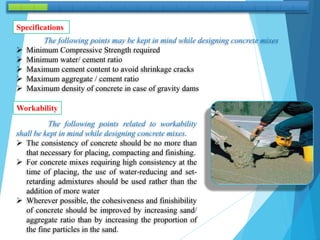

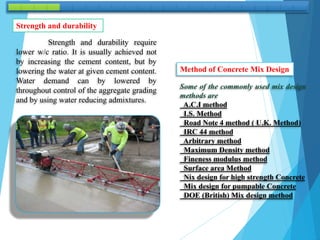

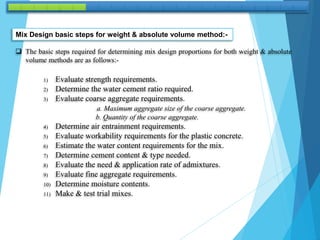

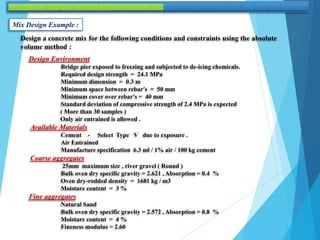

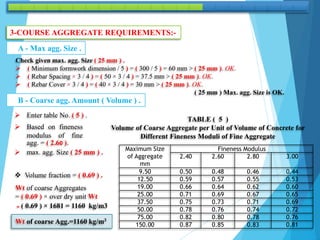

The document details concrete mix design, focusing on the selection of suitable ingredients and their proportions to achieve desired strength, workability, and durability while being cost-effective. It outlines objectives such as ensuring economic production without compromising on quality, as well as key considerations like cost, workability, strength, and durability. Various methods for mix design are discussed, including guidelines for evaluating strength requirements, water-cement ratios, aggregate requirements, and proper trial mix procedures.

![CONCRETE MIX DESIGN

Weight & Absolute Volume Method

( ACI Method )

Is the process of selecting suitable ingredients of concrete & determining their

relative quantities with the purpose of producing an economical concrete which

has certain minimum properties [ notably Workability, Strength & Durability].

Mix design

The following three qualities are required of properly proportioned concrete mixers:-

1) Acceptable workability of freshly mixed concrete.

2) Durability, strength & uniform appearance of hardened concrete.

3) Economy.

Several mix design methods have been developed over the years, ranging from an arbitrary

volume method. [e.g. (1:2:4) cement, Sand, Gravel].to the weight & absolute – volume

method.

The weight method provides relatively simple techniques for estimating mix proportions using

an assumed or known unit weight of concrete.

The absolute volume methods uses the specific gravity of each ingredient to calculate the unit

volume each will occupy in unit volume of concrete.](https://image.slidesharecdn.com/8-220910110744-bbba6e0e/85/Concrete-Mix-Design-pptx-5-320.jpg)

![1 – STRENGTH REQUIREMENTS:-

In order to compute the strength requirements for concrete mix design, three quantities

must be known:-

1) The specified compressive strength [fc

/)].

Cylinder at 28 days [ (fc

/) = 0.80 (fcu ) ] Cube at 28 days.

Cube at 28 days [ (fcu ) = 1.25 (fc

/) ] Cylinder at 28 days.

2) The variability or standard deviation (S), of concrete.

3) The allowable risk of making concrete with an unacceptable strength.

The standard deviation in the strength is determined for a plant by making batches of

concrete, testing the strength for many samples and computing the standard deviation.

The allowable risk has been established by the [(ACI)], One of the risk rules has been

established, states that there should be less than [(10%)] chance that the strength of a

concrete mix is less than the specified strength.

1. Standard deviation (S) is a measure of the dispersion or spread of the results.

2. The arithmetic mean [(X‾)] is simply the average of test results of all specimens tested.](https://image.slidesharecdn.com/8-220910110744-bbba6e0e/85/Concrete-Mix-Design-pptx-7-320.jpg)

![fcŕ= fc

/ + 1.34 (S) ……………… (1)

Where:-

fcŕ = Required average compressive strength (MPa) .

fc

/ = Specified compressive strength (MPa)

S = Standard deviation (MPa)

For mixes with a large standard deviation in strength, there is another risk criterion that requires.

fcŕ = fc

/ + 2.33 (S) – (3.45) ……… (2)

The larger of equations [(1) & (2)], will govern.

The standard deviation should be determined from at least (30) strength results.

If (S) is computed from [(15) to (30)] samples, then

fcŕ= fc

/ + 1.34 (S¯) …………..…… (3)

0r

fcŕ = fc

/ + 2.33 (S¯) – (3.45) ……… (4)

Where (S¯) is the product of

(S) multiplied by the following

modification factors(f). i.e,

S¯ = S . f](https://image.slidesharecdn.com/8-220910110744-bbba6e0e/85/Concrete-Mix-Design-pptx-8-320.jpg)

![ If fewer than (15) test are available, the following adjustments are made to the specified strength

instead of using equations [(1), ( 2 ) ,( 3 ) and (4)] as shown below:

Specified compressive strength

fc

/ ( MPa )

Required average compressive strength

fcŕ ( MPa )

< 20.7

20.7 to 34.5

> 34.5

fc

/ + 6.9

fc

/ + 8.3

fc

/ + 9.7

Example:

The design engineer specifies a concrete strength of [(31.0) MPa], Determine the

required average compressive strength for:-

(A) - A new plant where (S) is unknown.

(B) - A plant where [(S=3.6) MPa], for (17) test results.

(C) - A plant with extensive history of producing concrete with [(S=2.4) MPa].

(D) - A plant with extensive history of producing concrete with [(S=3.8) MPa].](https://image.slidesharecdn.com/8-220910110744-bbba6e0e/85/Concrete-Mix-Design-pptx-9-320.jpg)

![(A) – for fc‾ = 31 MPa , as (S) is unknown.

fcŕ = fc‾ + 8.3

= 31.0 + 8.3 = 39.3 MPa

Specified

compressive strength

fc

/ ( MPa )

Required average

compressive strength

fcŕ ( MPa )

< 20.7

20.7 to 34.5

> 34.5

fc

/ + 6.9

fc

/ + 8.3

fc

/ + 9.7

(B) - As (S) is based on ( 17 ) test results , between ( 15 – 30 ) so modified (S) to be used .

find ( f ) by inter potation.

f = {(1.16) – [(1.16 –1.08) / (20 –15)] × (17 –15)} f =1.13

i.e.

S¯ = f * S = 1.13×3.6 = 4.1 MPa

Now determine (fcŕ) basing on equ. ( 1 ) & ( 2 ) .

fcŕ= fc‾ + 1.34 (S)

fcŕ= 31.0 + [ (1.34)×(4.1) ] = 36.5 MPa

Or

fcŕ = fc‾ + 2.33 (S) – (3.45)

= {31.0 + [(2.33) × (4.1)] – (3.45)} = 37.1 MPa [govern]

Use fcŕ = 37.1 MPa

Number of tests (n) Modification Factor (f)

15

20

25

30 or more

1.16

1.08

1.05

1.00](https://image.slidesharecdn.com/8-220910110744-bbba6e0e/85/Concrete-Mix-Design-pptx-10-320.jpg)

![(C) - As (S) is based on more results , than (30 ) results

(fcŕ) to be calculated directly from equ. ( 1 ) & ( 2 ) .

fcŕ= fc‾ + 1.34 (S)

= {31.0 + [ (1.34)×(2.4) ] } = 34.2 Mpa [govern]

Or

fcŕ = fc‾ + 2.33 (S) – (3.45)

= {31.0 + [(2.33) × (2.4)] – (3.45)} = 33.1 MPa

Use fcŕ = 34.2 MPa

(D) Same as C

fcŕ= fc‾ + 1.34 (S)

= 31.0 + [ (1.34)×(3.8) ] = 36.1 MPa

or

fcŕ = fc‾ + 2.33 (S) – (3.45)

= {31.0 + [(2.33) × (3.8)] – (3.45)} = 36.4 MPa [govern]

Use fcŕ = 36.4 MPa](https://image.slidesharecdn.com/8-220910110744-bbba6e0e/85/Concrete-Mix-Design-pptx-11-320.jpg)

![Solution :

1- STRENGTH REQUIREMENTS :-

S = 2.4 MPa ( enough samples so that no correction is needed )

fcŕ= fc‾ + 1.34 (S) = 24.1 + [ (1.34)×(2.4) ] = 27.3 MPa [govern] Or

fcŕ = fc‾ + 2.33 (S) – (3.45) = {24.1 + [(2.33) × (2.4)] – (3.45)} = 26.2 MPa fcŕ = 27.3 MPa

2 - WATER – CEMENT RATIO:-

For fcŕ = 27.3 (MPa)

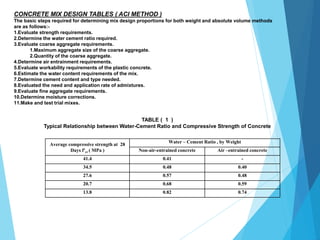

TABLE ( 1 ) Typical Relationship between Water-Cement Ratio and Compressive Strength of Concrete

Average compressive strength

at 28 Days f'cr ( MPa )

Water – Cement Ratio , by Weight

Non-air-entrained concrete Air –entrained concrete

41.4 0.41 -

34.5 0.48 0.40

27.6 0.57 0.48

20.7 0.68 0.59

13.8 0.82 0.74

Enter table No. ( 1 ) , & by interpolation [ (W/C) = 0.48 ].

Δ fc‾ = 27.6 – 20.7 = 6.9 (MPa)

Δ (W/C) = 0.59 – 0.48 = 0.11

For ( 27.6 -27.3 ) = 0 .3 Δ (W/C) = {( 0.3 × 0.11 ) / 6.9 } = 0.0047

(W/C) = 0.48 + 0.0047 = 0.48

0](https://image.slidesharecdn.com/8-220910110744-bbba6e0e/85/Concrete-Mix-Design-pptx-13-320.jpg)

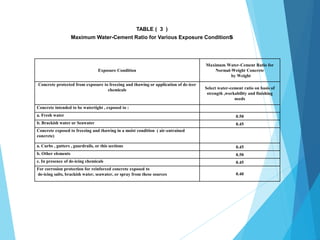

![[ ( W/C ) = 0.45 ] The smaller value of table ( 1 & 3 ) governs

For exposure condition ( exposed to freezing & thawing subjected the de-icing chemicals ) .

Enter table No.( 3 ) , Max. Permissible [ ( W/C ) = 0.45 ].

TABLE ( 3 )

Maximum Water-Cement Ratio for Various Exposure Conditions

Exposure Condition

Maximum Water-Cement Ratio

for Normal-Weight Concrete

by Weight

Concrete protected from exposure to freezing and thawing or

application of de-icer chemicals

Select water-cement ratio on

basis of strength ,workability

and finishing needs

Concrete intended to be watertight , exposed to :

a. Fresh water 0.50

b. Brackish water or Seawater 0.45

Concrete exposed to freezing and thawing in a moist condition (

air-entrained concrete)

a. Curbs , gutters , guardrails, or this sections 0.45

b. Other elements 0.50

c. In presence of de-icing chemicals 0.45

For corrosion protection for reinforced concrete exposed to

de-icing salts, brackish water, seawater, or spray from these

sources

0.40](https://image.slidesharecdn.com/8-220910110744-bbba6e0e/85/Concrete-Mix-Design-pptx-14-320.jpg)

![7-CEMENT CONTENT REQUIREMENTS:-

For [(W/C) = 0.45 ] & water content = ( 148 kg/m3 )

[ Cement Content = ( 148 / 0.45 )] = ( 329 kg/m3 )

Having minimum cement content requirement for freeze & thawing & de-icing chemicals

= ( 334 kg/m3 )

Cement Content = ( 334 kg/m3 )

8-ADMIXTURE :-

For Air content = ( 7 % ) , Cement Content = ( 334 kg/m3 ) .

Admixture required = { 6.3 × 7 × ( 334 /100 )} = ( 147 ml /m3 ) .

Admixture Required = ( 147 ml /m3 ) .](https://image.slidesharecdn.com/8-220910110744-bbba6e0e/85/Concrete-Mix-Design-pptx-19-320.jpg)

![10-MOISTURE CORRECTIONS:-

Mix design should be based on (S.S.D.) [ Saturation Surface Dry ], condition for fine &

coarse aggregate .

The final step in the mix design process is to adjust the weight of water & aggregates to

acount for the existing moisture content of the aggregates. If moisture content of the

aggregates is more than the (S.S.D.) moisture content , the weight of mixing water is reduced

by an amount equal to the free weight of the moisture on the aggregate.

Similarly, if the moisture content is below, (S.S.D.) moisture content, the mixing water must

be increased.

Coarse aggregates : Need 1160 kg / m3 in SSD condition , so increase by 3 % for excess

moisture

Moist coarse aggregates = 1160 x 1.03 = 1195 kg / m3

Fine aggregates : Need 599 kg / m3 in SSD condition , so increase by 4 % for excess

moisture

Moist fine aggregates = 599 x 1.04 = 623 kg / m3

Water : Reduce for free water on aggregates

= 148 – 1160 ( 0.03 – 0.004 ) - 599 ( 0.04 – 0.008 ) = 99 kg / m3](https://image.slidesharecdn.com/8-220910110744-bbba6e0e/85/Concrete-Mix-Design-pptx-21-320.jpg)

![Summary : Water 99 kg

Cement 334 kg

Fine aggregates 623 kg

Coarse aggregates 1195 kg

Admixture 147 ml

Concrete mix W (Water): C ( Cement) : F ( Fine agg.) : C ( Coarse agg.) : Ad (Admixture )

99 : 334 : 623 : 1195 : 147ml

0.2964 : 1 : 1.8653 : 3.5778 : 147 ml

11 - TRIAL MIXES:-

To be done on site, to check the mix design.

Trial batch using three (Cubes) [ (150 ) × (150 ) × (150 ) mm ] ,

or cylinder [( 150 ) × ( 300 ) mm ] , cured for [ (28) days ] and tested for compression strength.

Finally mix design ratio should be based on the weight of the mix ingredients & the site

engineer can convert it to volumes.](https://image.slidesharecdn.com/8-220910110744-bbba6e0e/85/Concrete-Mix-Design-pptx-22-320.jpg)