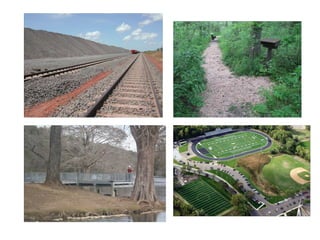

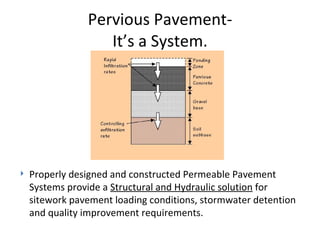

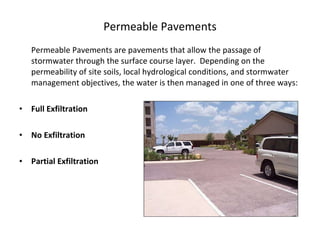

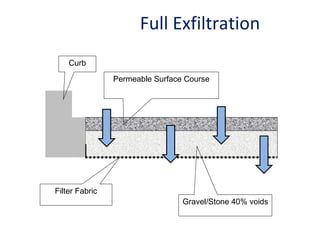

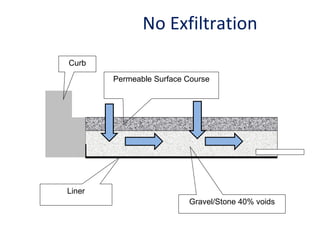

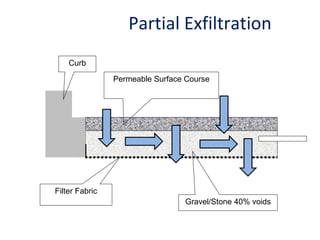

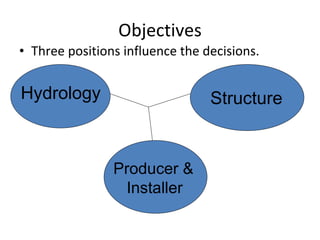

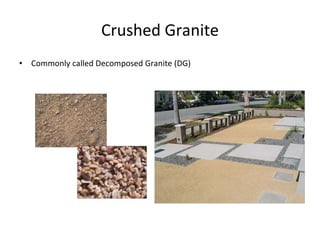

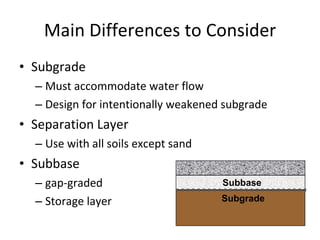

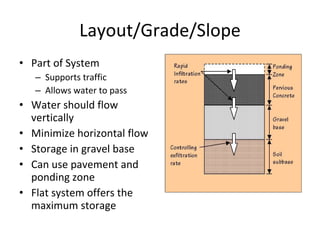

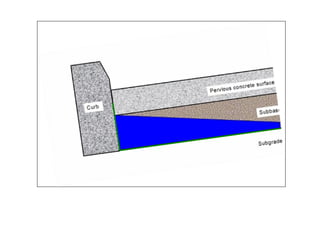

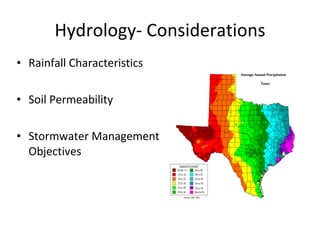

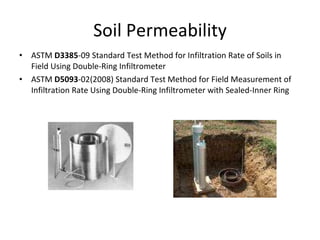

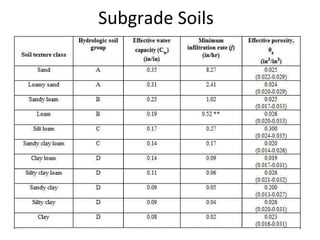

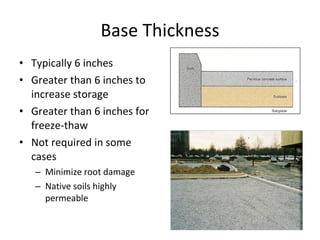

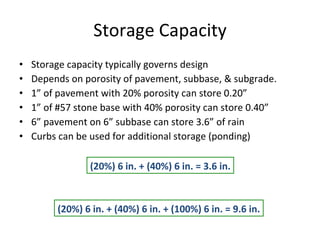

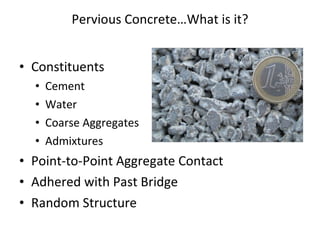

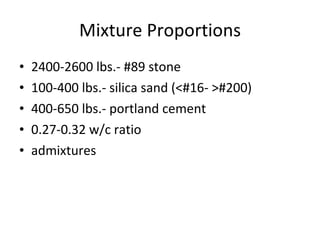

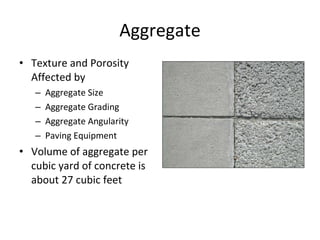

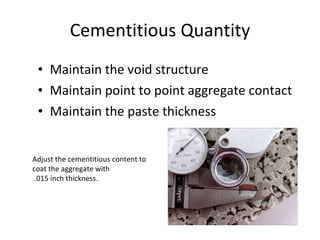

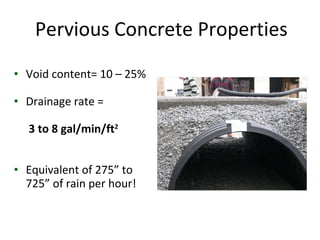

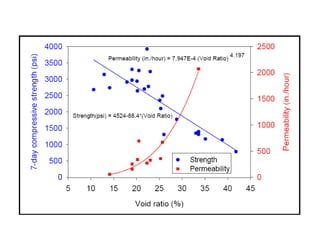

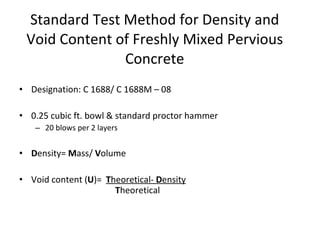

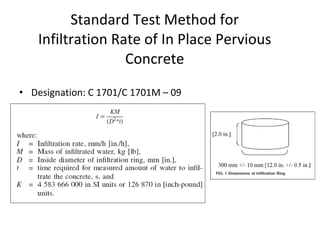

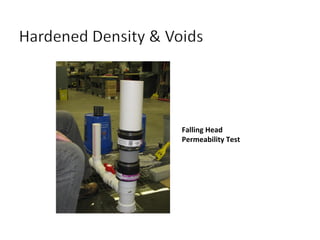

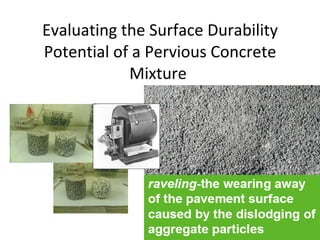

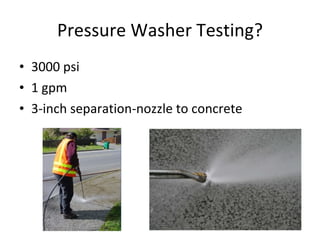

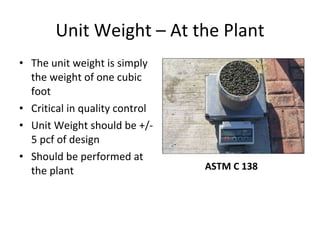

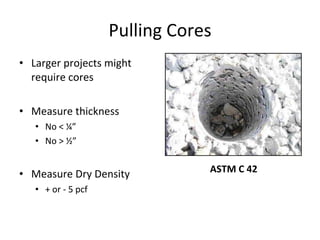

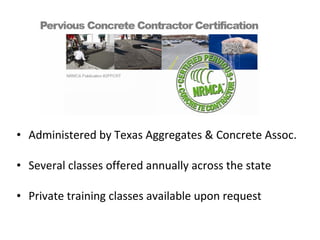

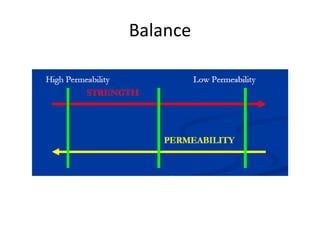

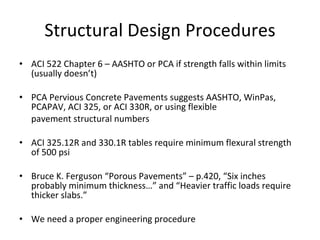

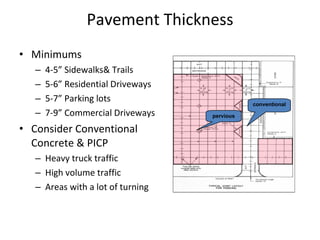

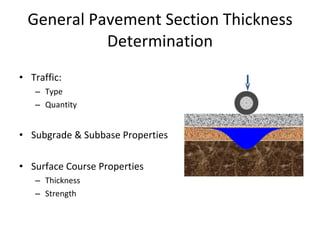

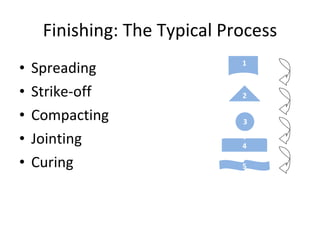

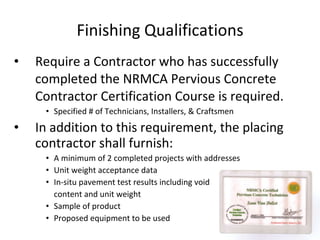

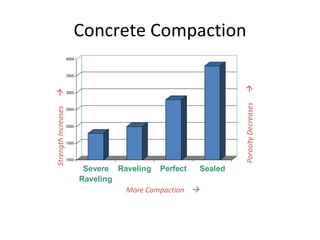

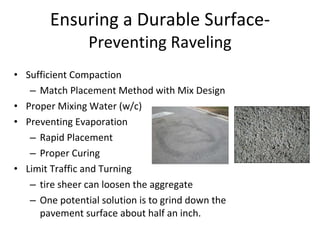

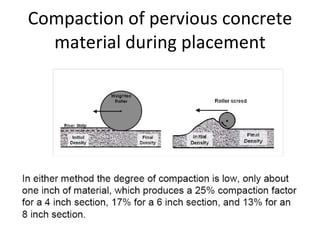

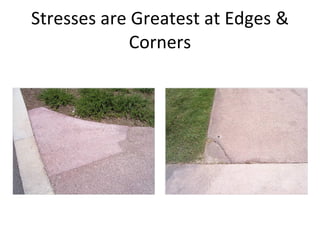

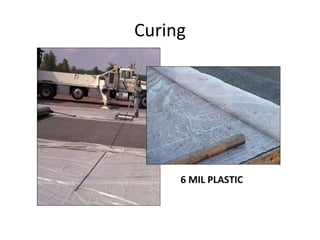

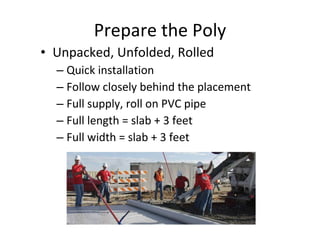

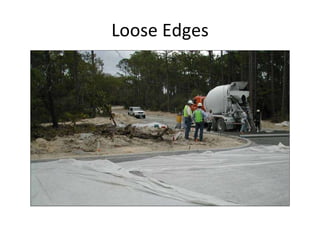

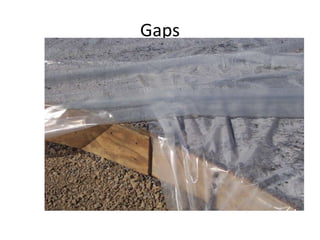

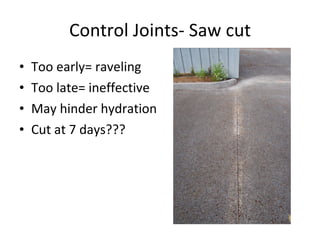

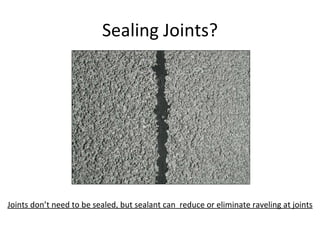

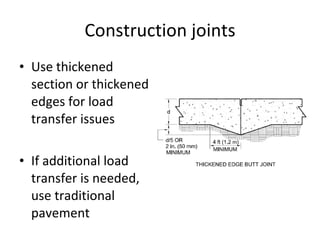

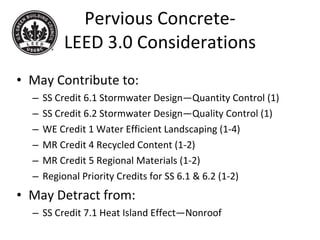

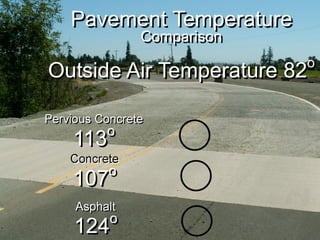

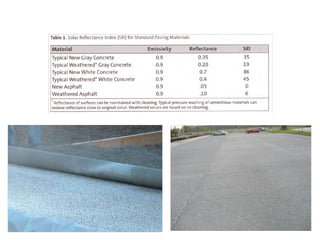

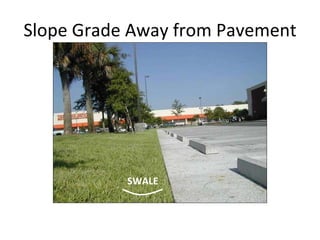

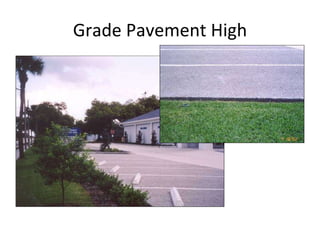

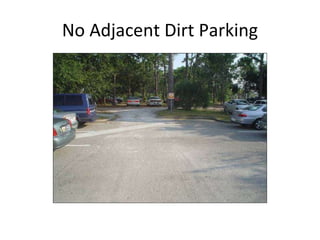

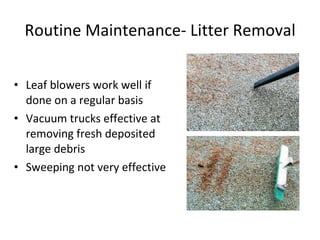

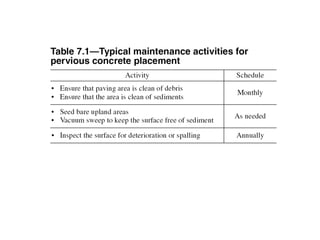

The document provides a comprehensive overview of pervious concrete and permeable pavements, highlighting their benefits for stormwater management, including runoff reduction and water quality improvement. It discusses design considerations, appropriate materials, construction techniques, and maintenance needs, emphasizing the importance of site-specific approaches and engineering standards. The text also outlines testing methods, potential issues, and recommended practices for effective installation and long-term performance of pervious concrete systems.

![Questions? For additional information or assistance, Please call or email: Sean Van Delist 210-883-8060 [email_address]](https://image.slidesharecdn.com/perviousconcreteasla20102-12658165874067-phpapp01/85/Pervious-Concrete-Getting-Down-to-the-Details-176-320.jpg)