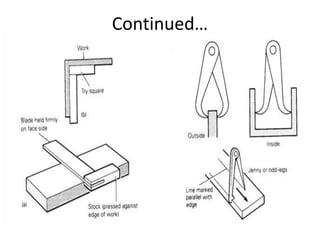

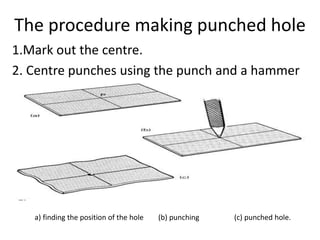

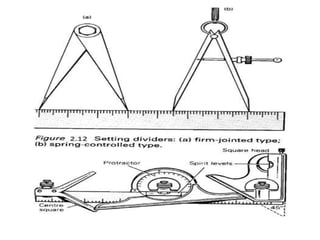

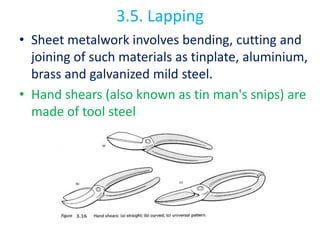

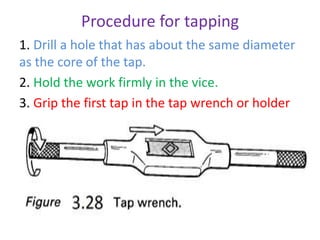

This document provides an overview of performing bench work in a training module. It discusses classifying materials as metallic or non-metallic and then further classifying metals. Several types of metals like ferrous, non-ferrous, plain carbon steels, and alloys are defined based on their composition and properties. Common bench work operations like cutting using different saws, hacksaws and knives, chipping using chisels, and filing metal pieces are described along with guidelines for safe and proper techniques.