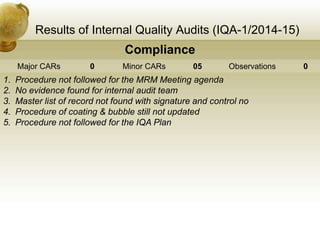

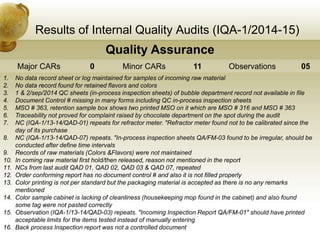

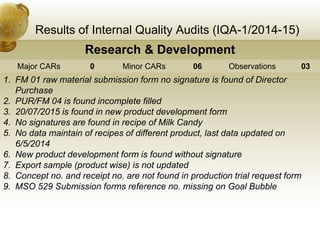

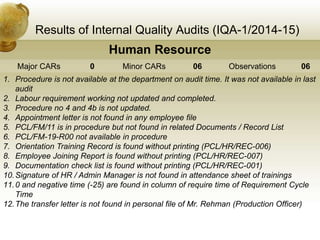

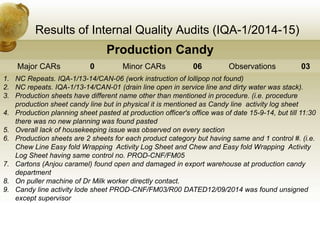

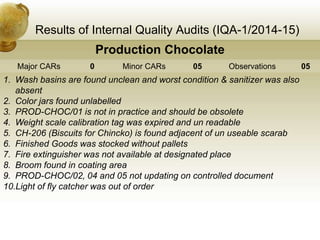

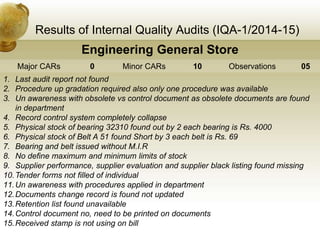

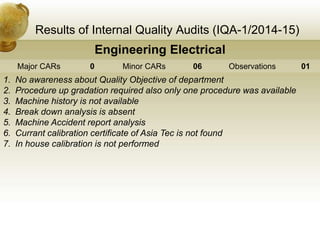

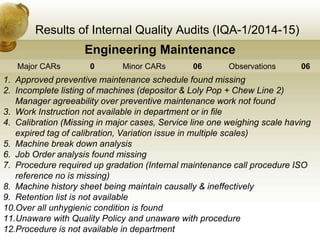

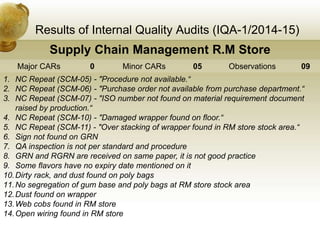

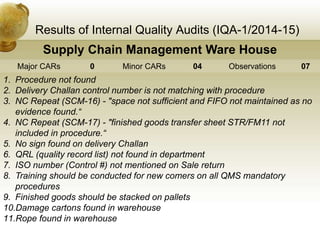

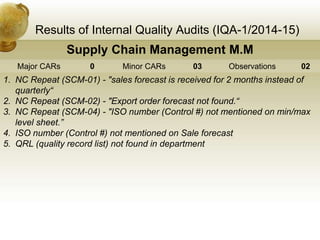

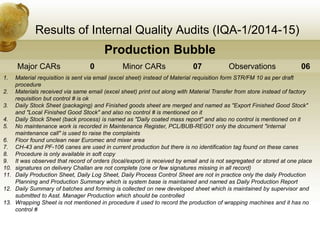

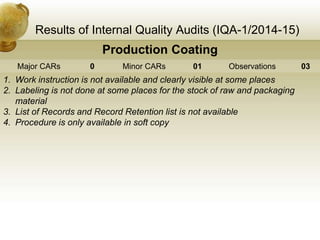

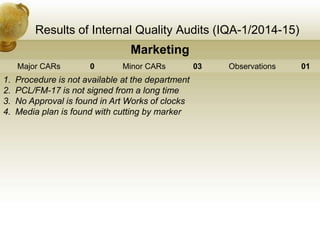

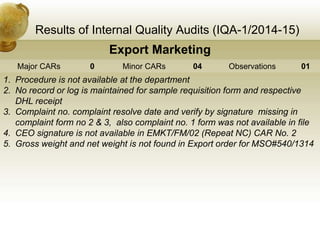

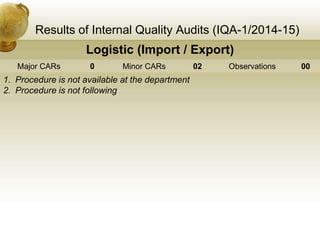

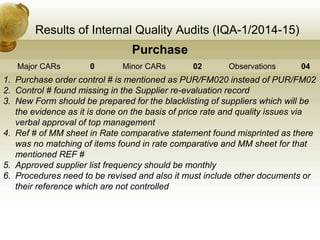

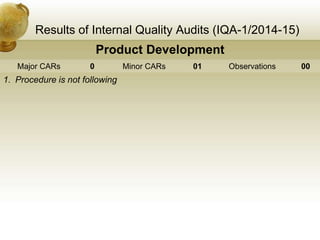

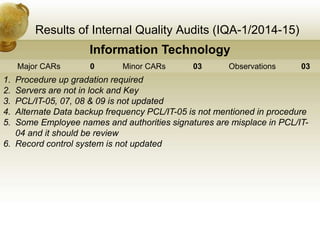

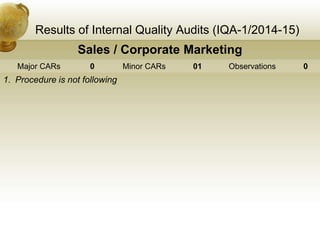

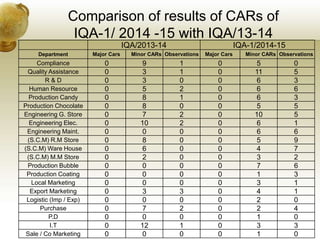

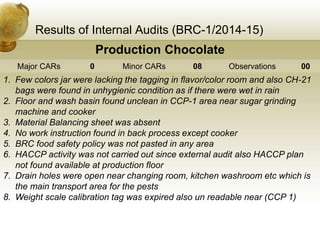

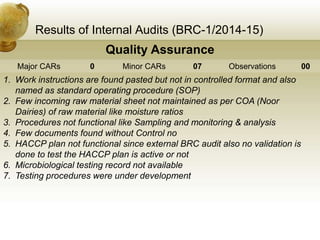

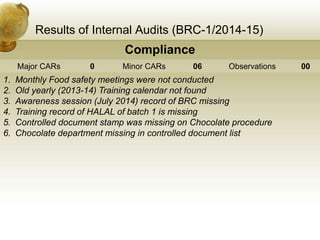

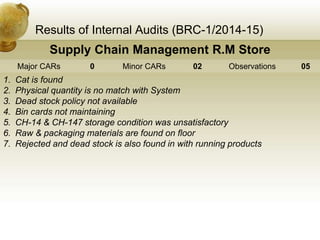

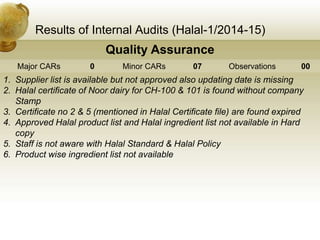

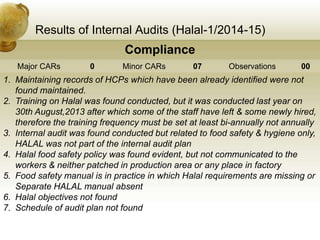

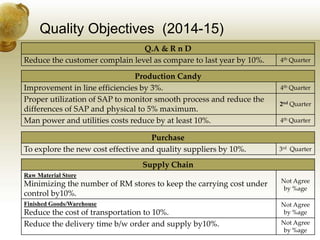

The document summarizes the results of the first internal quality audit conducted from September 15-22, 2014 by Pearl Confectionery. Several departments had minor non-conformances related to documentation issues such as missing or outdated procedures, incomplete records, or lack of document control. No major non-conformances were found. The audit also identified observations for potential quality improvements such as improved cleaning, labeling, or maintenance practices. In total, there were 76 minor non-conformances and 52 observations across all audited departments.