This document presents a project presentation on "Manufacturing of Paver Blocks using Construction and Demolition Wastes". The presentation discusses using construction and demolition waste to manufacture paver blocks in order to minimize waste and reduce environmental impacts. It provides an introduction to the topic, objectives of the project which include reuse of waste and increasing block strength. A literature review is presented summarizing several papers on using various wastes like glass powder, marble dust and steel aggregates in paver block production. The methodology explains the process of material collection, mix design, block casting and testing of blocks made with cement and C&D steel waste.

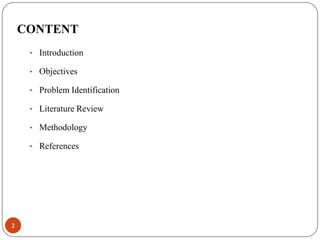

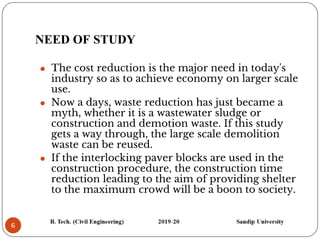

![LITERATURE REVIEW

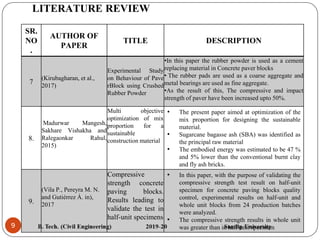

7

SR.

NO.

AUTHOR OF

PAPER

TITLE DESCRIPTION

1

(Pattnaik Truptimala [et

al.,

2018)

Manufacture of

interlocking concrete

paving blocks with flyash

and glass powder

• In the paper, concrete paving blocks may be

produced with locally available cement,

aggregates, fly ash and waste glass powder as the

mineral admixture.

•The study indicated that fly ash and waste glass

powder can effectively be used as cement

replacement without substantial change in strength

2.

(Gencel Osman [et al.].,

2012)

Properties of concrete

paving blocks made with

waste marble

• This paper shows the use of materials like

Portland Cement, Dry and clean natural

river sand, crushed sand and crushed stone

whereas Crushed waste marble and dust

used were obtained from marble processing

plants in Turkey.

• This paper concluded that their method of

incorporating marble waste is only limited

by incidental costs

3.

(Wang Xinyi, Chin Chee

Seong and Xia jun, 2019)

Material

Characterization for

Sustainable Concrete

Paving Blocks

• This Paper aims to study the property

variations of sustainable concrete paving

block using different contents of

construction wastes.

• Mixing crushed glass in the concrete paving

blocks as a type of coarse aggregates can

improve the blocks’ strength and decrease

the blocks’ water absorption](https://image.slidesharecdn.com/paverblocks-230601025310-8aafbfd4/85/Paver-blocks-pptx-7-320.jpg)

![11

REFERENCES

1. A. Panimayam [et al.] Utilisation of Waste Plastics as a Replacement of Coarse Aggregate in Paver Blocks [Journal] //

International Journal of ChemTech Research. - Coimbatore, India : Sai Scientific Communications

Research, 2017. - 8 : Vol. 10. - pp. 211-218. - ISSN: 0974-4290.

2. Aamar Danish, Mohammad Ali Mosaberpanah and Muhammad Usama Salim Past and present

techniques of self-healing in cementitious materials: A critical review on efficiency of implemented

treatments [Journal] // Journal of Materials Research and Technology. - North Cyprus, Turkey : Elsevier,

2020. - 9 : Vol. 3. - pp. 6883–6899.

3. Agrawal Nikhil S [et al.] Review Paper on Sustainable Use of Debris in Paver Blocks [Journal] // Indian

Journal of Applied Research. - Pune : [s.n.], December 2015. - 12 : Vol. 5. - pp. 243-245. - ISSN - 2249-

555X.

4. Albayrak Gulcag and Albayrak Ugur Investigation of Ready Mixed Concrete Transportation Problem

Using Linear Programming and Genetic Algorithm [Journal] // Civil Engineering Journal. - Turkey : [s.n.],

October 2016. - 10 : Vol. 2. - pp. 491-496.

5. Anastasiou E K, Liapis A and Papachristoforou M Life Cycle Assessment of Concrete Products for

Special Applications Containing EAF Slag [Journal] // Procedia Environmental Sciences. - Thessaloniki,

Greece : Elsevier, 2017. - pp. 469-476.

6. G Anusha [et al.] Experimental Study on Properties of Concrete Paver Blocks by Partially Replacing

Cement with Granite Powder [Conference] // IOP Conf. Series: Materials Science and Engineering. - [s.l.] :

IOP Publishing, 2021.

7. Gautam Pradeep Kumar [et al.] Sustainable use of waste in flexible pavement: A review [Journal] //

Construction and Building Materials. - Jaipur : Elsevier, 2018. - Vol. 180. - pp. 239-253.

8. Gawatre Dinesh W [et al.] To Improve Mechanical Properties of Concrete Paver Blocks [Journal] // IOSR

Journal of Mechanical and Civil Engineering. - June 2017. - 3 : Vol. 14. - pp. 147-151. - ISSN: 2320-334X.](https://image.slidesharecdn.com/paverblocks-230601025310-8aafbfd4/85/Paver-blocks-pptx-11-320.jpg)

![12

REFERENCES

8. Gencel Osman [et al.] Properties of concrete paving blocks made with waste marble [Journal] // Journal of Cleaner Production. -

Turkey : Elsevier, 2012. - pp. 62-70.

9. Hallale Shivkumar, Swami Suraj and Londhe Vikas Utilization of demolished bulding waste in paving block with coir fibre

[Journal]. - Akurdi, Maharashtra, India : [s.n.], 2017. - 3 : Vol. 3. - pp. 2395-4396.

10.Iheanyichukwu Chigozirim G., Umar Sadiq A. and Prince C. Ekwueme A REVIEW ON SELF-HEALING CONCRETE USING

BACTERIA [Journal] // Sustainable Structure and Materials. - 2018. - 2 : Vol. 1. - pp. 12-20.

11.Indian Sandard of Precast Concrete Blocks for Paving - Specification (IS15658) [Report] = IS 15658 / Bureau of Indian Standards ;

Flooring, Wall Finishing and Roofing Sectional Committee, CED 5. - New Delhi : [s.n.], 2006. - pp. 1 - 27.

12.Indra Jaya and Rambe Andy Putra Analysis Comparison of Cost and Time of Concrete and Paving Block Jobs in the

Implementation of Village Road Development using Village fund Project [Conference] // In Proceedings of the International

Conference of Science, Technology, Engineering, Environmental and Ramification Researches. - Indonesia : Science and Technology

Publications. - pp. 368-374. - ISBN: 978-989-758-449-7.

13.Janani R and Bharani Priya A Study of Paver Blocks from Construction wastes [Journal] // Journal of Applied Science and

Computations. - Tamilnadu, India : [s.n.], December 2018. - 12 : Vol. 5. - pp. 1186-1190. - ISSN NO: 1076-5131.

14.Jaya Indra and Rambe Andy Putra Analysis Comparison of Cost and Time of Concrete and Paving Block Jobs in the

Implementation of Village Road Development using Village Fund Budget [Conference] // International Conference of Science,

Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018). - Indonesia : SCITEPRESS – Science

and Technology Publications Ltd, 2018. - pp. 368-374. - ISBN: 978-989-758-449-7.

15.Kirubagharan P. [et al.] Experimental Study on Behaviour of Pave rBlock using Crushed Rubber Powder [Journal] // International

Journal of Civil Engineering and Technology (IJCIET). - [s.l.] : IAEME, Scopus Indexed, March 2017. - 3 : Vol. 8. - pp. 582-589. -

ISSN Print: 0976-6308.

16.Lavanya Ganesan and Chippymol James Strength characteristics of Concrete Paver Blocks embedded with PET Fibres [Journal] //

International Journal of Engineering Research And Management (IJERM). - September 2019. - 9 : Vol. 6. - pp. 62-64. - ISSN: 2349-

2058.](https://image.slidesharecdn.com/paverblocks-230601025310-8aafbfd4/85/Paver-blocks-pptx-12-320.jpg)