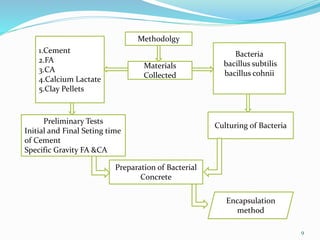

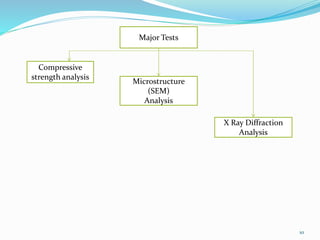

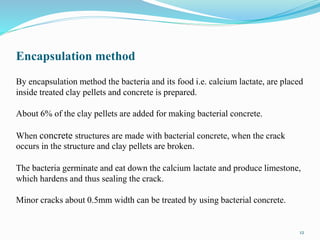

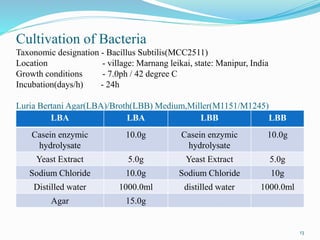

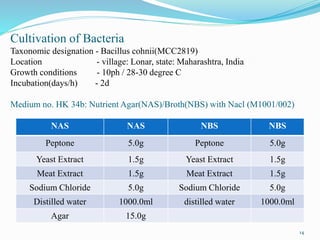

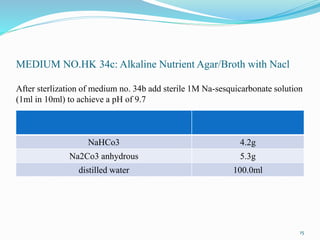

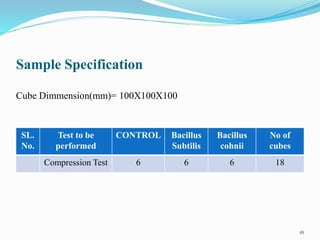

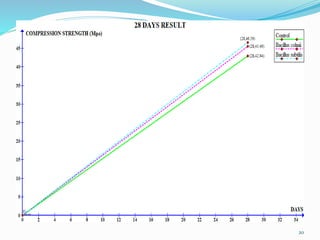

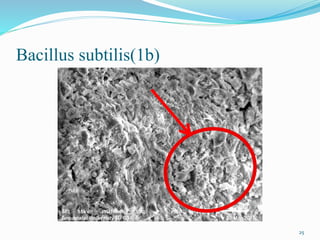

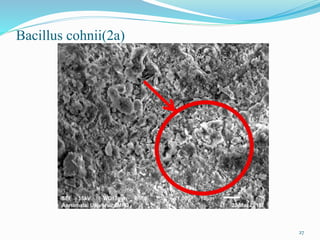

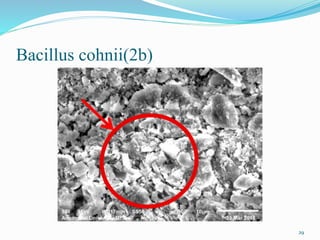

This document discusses the development of self-healing sustainable concrete utilizing bacterial carbonate precipitation to repair cracks and enhance compressive strength. The study compares different bacteria, namely Bacillus subtilis and Bacillus cohnii, and evaluates their effectiveness through various tests, showing improved durability and strength over conventional methods. The findings suggest that incorporating bacteria in concrete can provide an eco-friendly alternative for maintaining structural integrity in construction.

![Reference

[1] Wasim Khaliq, Muhammad Basit Ehsan, Crack healin in concrete using

various bio influenced self-healing techniques, Construction and Building

Materials 102 (2016) 349–357

[2] Henk M. Jonkers, Arjan Thijssen, Gerard Muyzer, Oguzhan Copuroglu,

Erik Schlangen, Application of bacteria as self-healing agent for the

development of sustainable concrete, Ecological Engineering 36 (2010)

230–235.

[3] Mian Luo, Chun-xiang Qian, Rui-yang Li, Factors affecting crack

repairing capacity of bacteria-based self-healing concrete, Construction

and Building Materials 87 (2015) 1–7

31](https://image.slidesharecdn.com/selfhealingconcrete-191126070730/85/Self-healing-concrete-31-320.jpg)

![[4]S. A. L. de Koster, R. M. Mors, H. W. Nugteren, H.M. Jonkers,G.M.H.

Meestersa, J. R. van Ommena, Geopolymer coating of bacteria-

containing granules for use in self- healing concrete, Procedia

Engineering 102 ( 2015 ) 475 – 484.

[5]S.A. Abo-El-Enein , A.H. Ali b, Fatma N. Talkhan , H.A. Abdel- Gawwad ,

Application of microbial biocementation to improve the physico-mechanical

properties of cement mortar, HBRC Journal (2013)9,36–40.

[6]Navneet Chahal, Rafat Siddique, Anita Rajor , Influence of bacteria on the

compressive strength, water absorption and rapid chloride permeability of

fly ash concrete, Construction and Building Materials 28 (2012) 351-356

32](https://image.slidesharecdn.com/selfhealingconcrete-191126070730/85/Self-healing-concrete-32-320.jpg)

![[7]Mayur Shantilal Vekariya1, Prof. Jayeshkumar Pitroda, Bacterial Concrete: New

Era For Construction Industry, International Journal of Engineering Trends and

Technology (IJETT) – Volume 4 Issue 9- Sep 2013.

[8]P. Ghosh, S. Mandal, B.D. Chattopadhyay, S. Pal, Use of microorganism to

improve the strength of cement mortar, Cement and Concrete Research 35

(2005) 1980 – 1983.

[9]S.W. Tang, Y. Yao, C. Andrade,Recent durability studies on concrete

structure, Cement and Concrete Research(2015).

[10]Y. C. Guo, X. Wang, Z. Yan & H. Zhong, Current progress on biological self-

healing concrete, ISSN: 1432-8917 (Print) 1433- 075X.

33](https://image.slidesharecdn.com/selfhealingconcrete-191126070730/85/Self-healing-concrete-33-320.jpg)

![[11] N. De Belie & J. Wang, Bacteria-based repair and self-healing o

concrete, ISSN: 2165-0373 (Print) 2165-0381.

[12] Jing Xu, Wu Ya, Multiscale mechanical quantification of self-healing

concrete incorporating non-ureolytic bacteria-based healing agent,

Cement and Concrete Research 64 (2014) 1–10

[13] J.Y. Wang a,b, H. Soens c, W. Verstraete b, N. De Belie, Self-healing

concrete by use of microencapsulated bacterial spores, Cement and

Concrete Research 56 (2014) 139–152.

[14] Peter Duxson, John L. Provis, Grant C. Lukey, Jannie S.J. van

Deventer, The role of inorganic polymer technology in the

developmentof ‘green concrete’, Cement and Concrete Research 37

(2007) 1590–1597.

[15] H.K. Kim, S.J. Park, J.I. Han, H.K. Lee, Microbially mediated

calcium carbonate precipitation on normal and lightweight concrete,

Construction and Building Materials 38 (2013) 1073–1082.

34](https://image.slidesharecdn.com/selfhealingconcrete-191126070730/85/Self-healing-concrete-34-320.jpg)