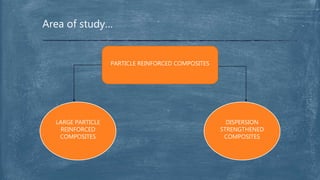

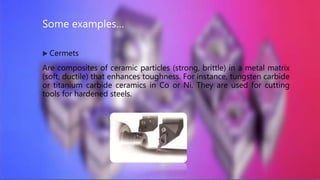

The document discusses the application of composite material technology in design engineering, specifically focusing on particle-reinforced composites. It explains the classification, properties, and practical applications of different types of composites such as large particle reinforced composites and dispersion-strengthened composites. Examples include vulcanized rubber, concrete, and specific metal matrix composites that enhance toughness and strength under various conditions.