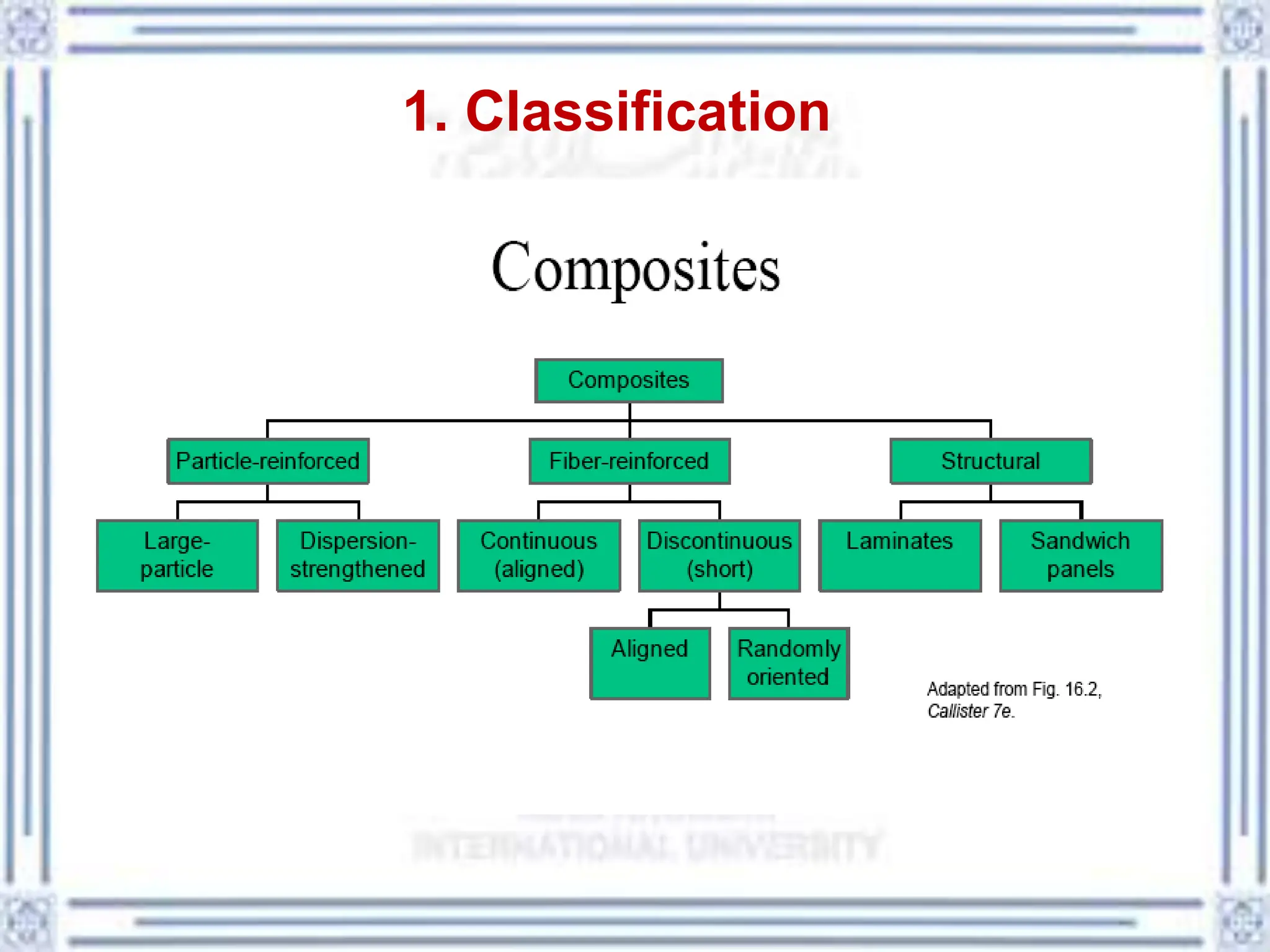

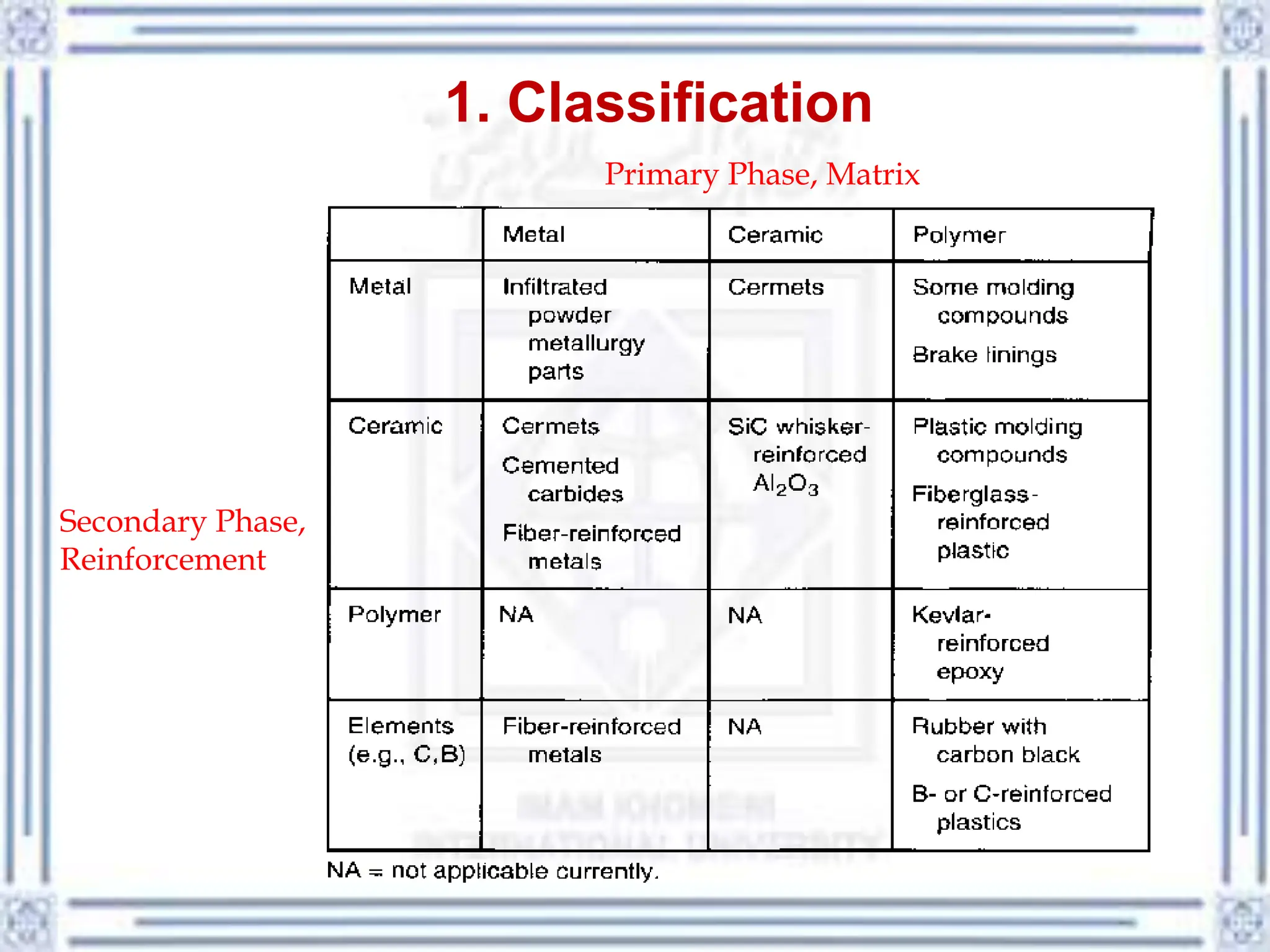

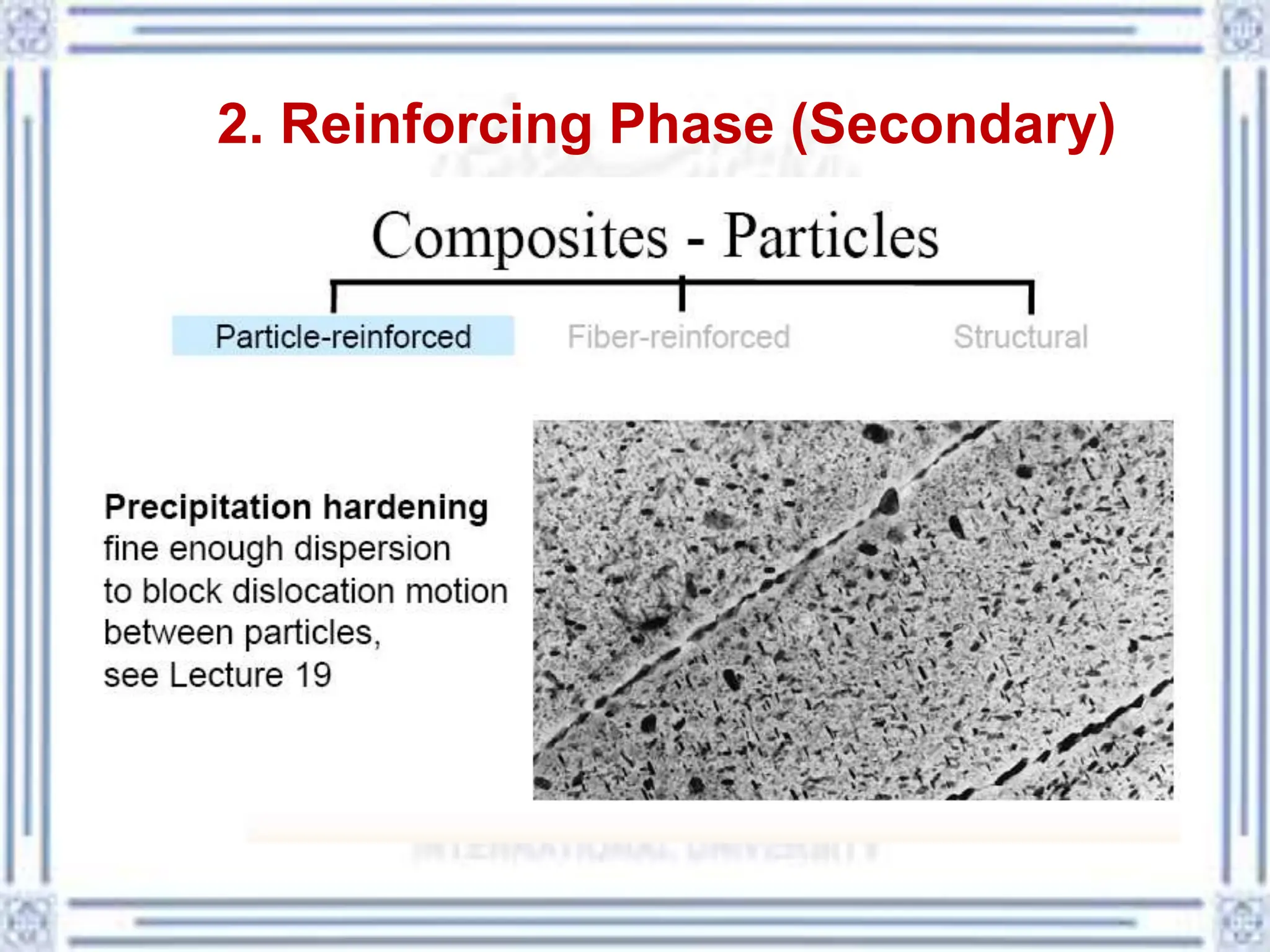

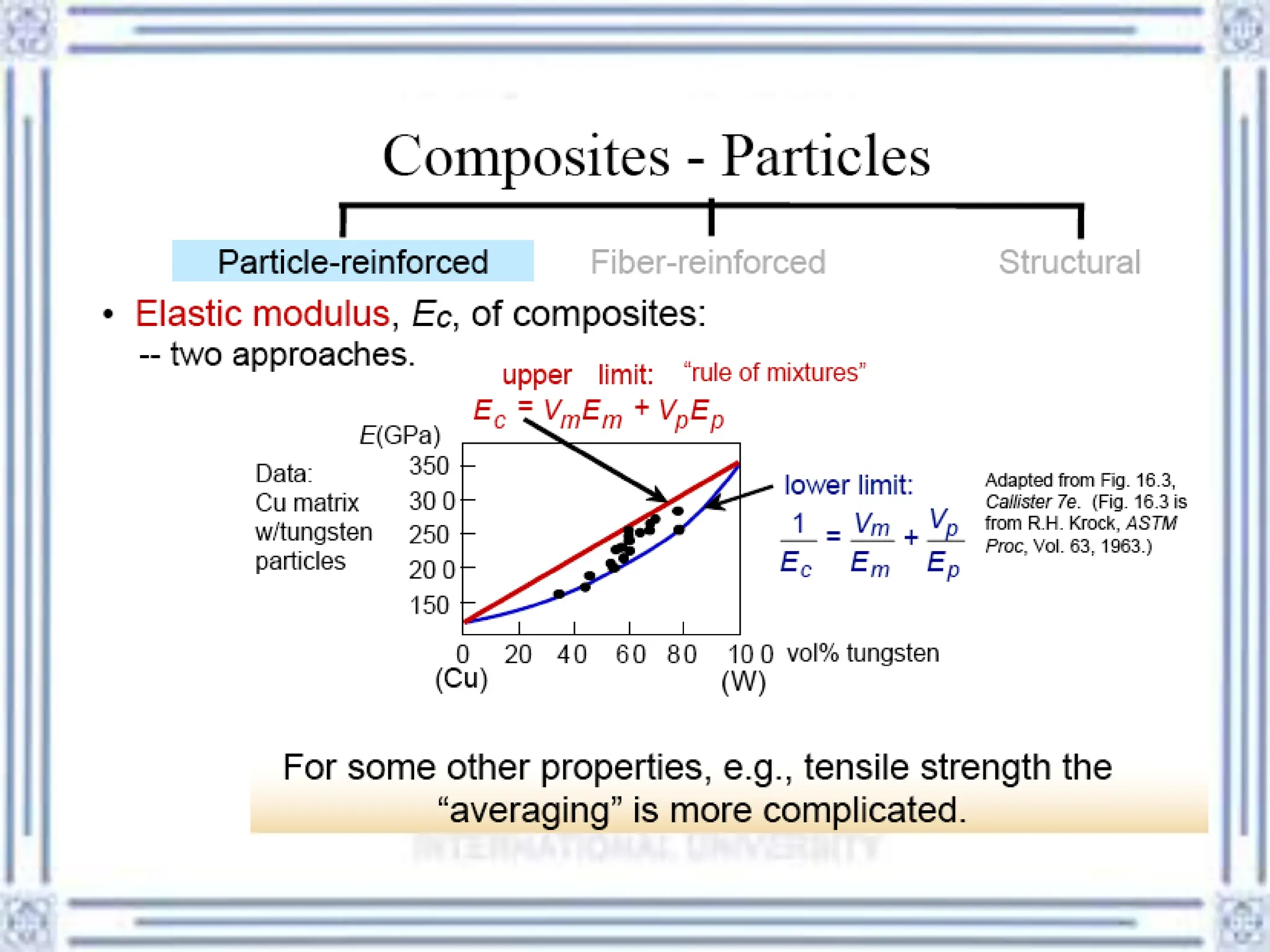

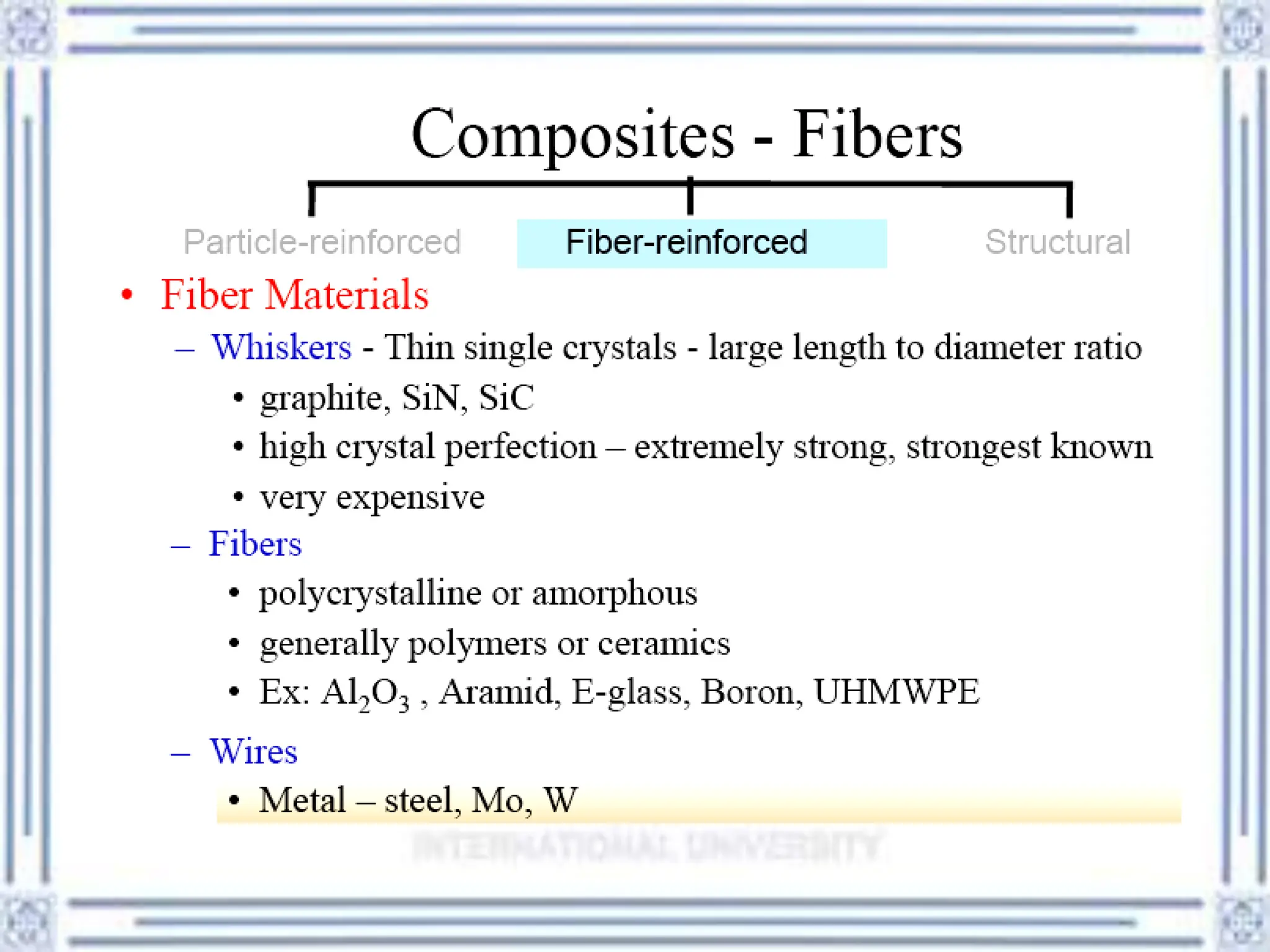

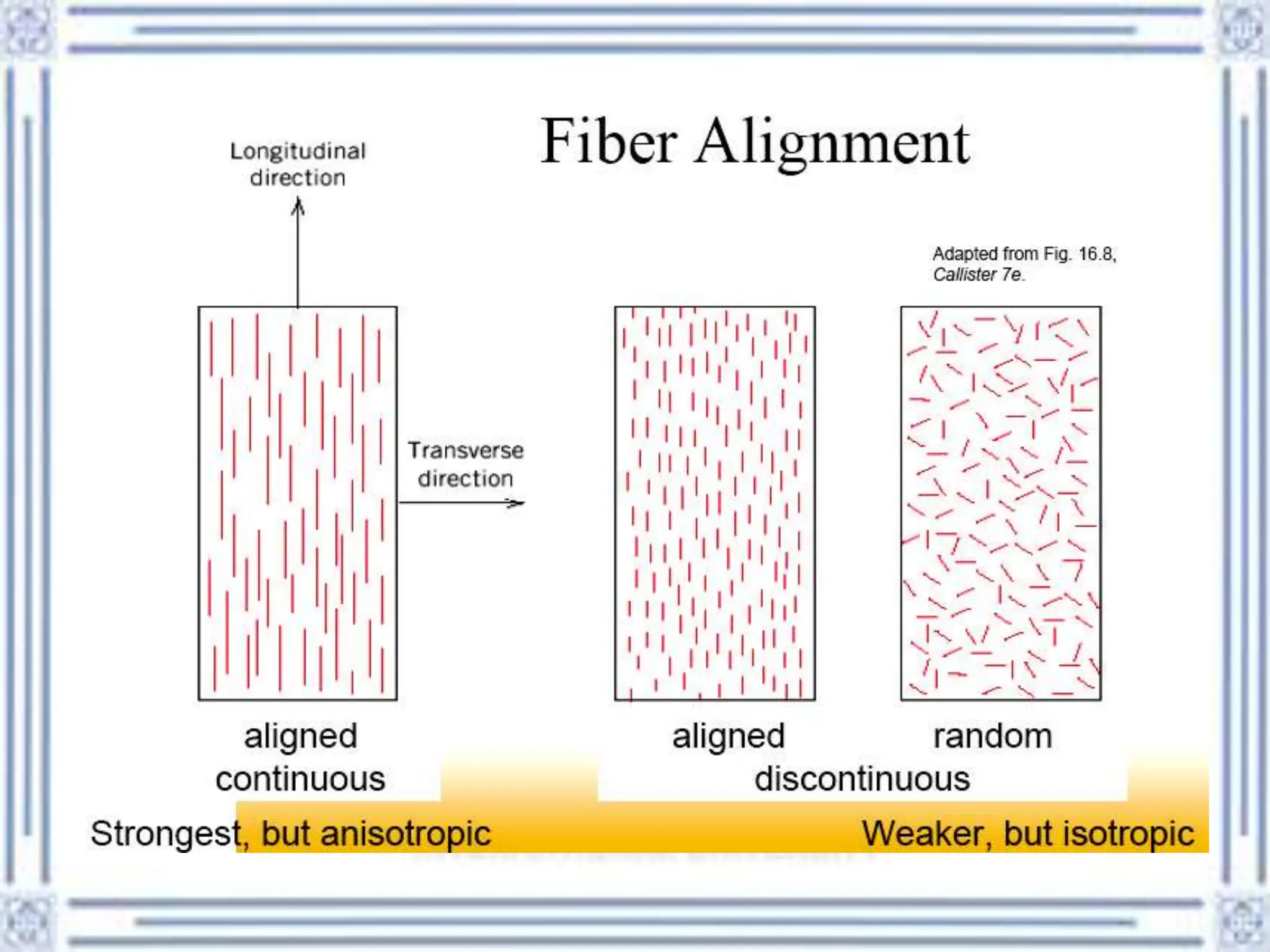

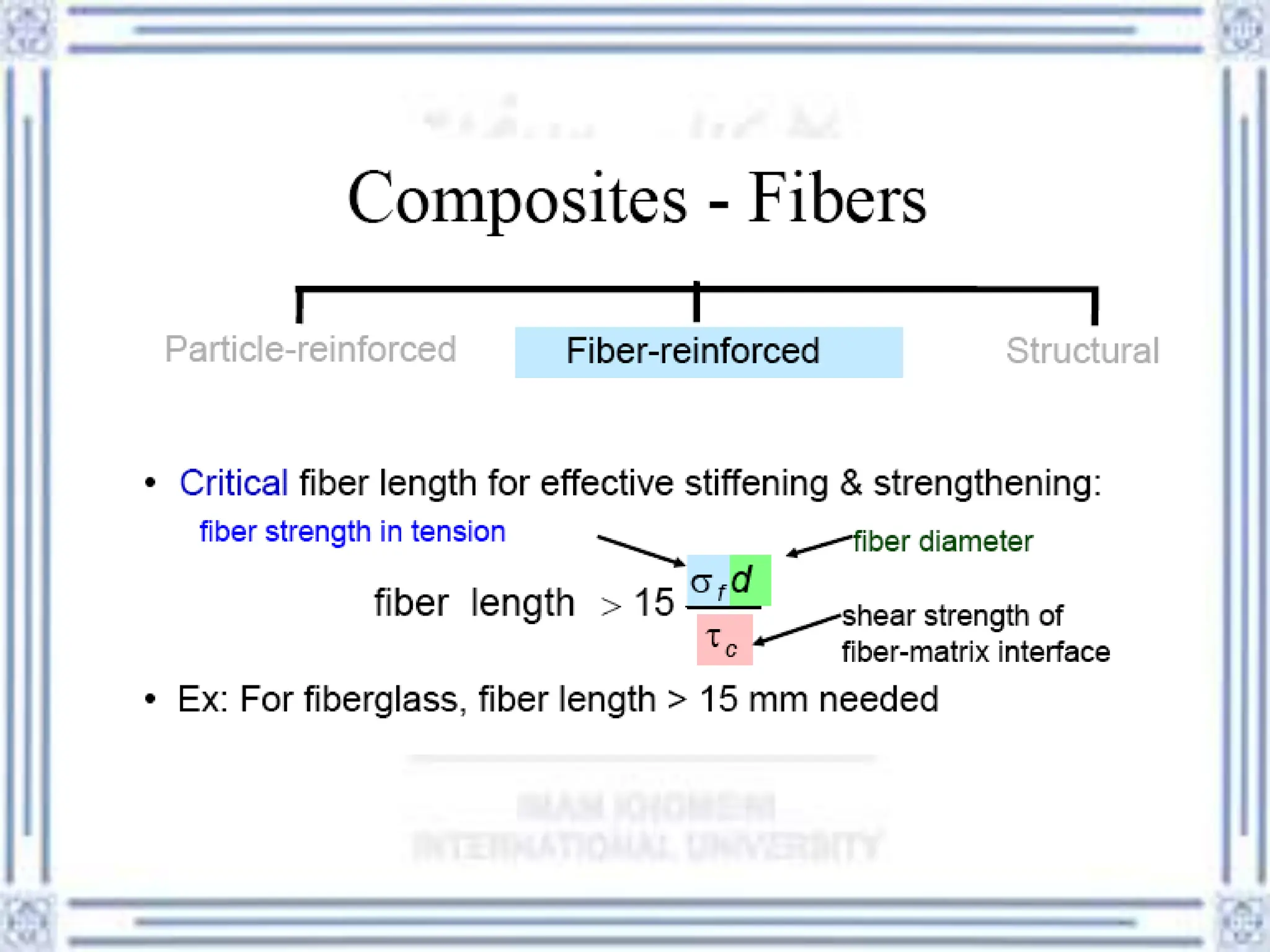

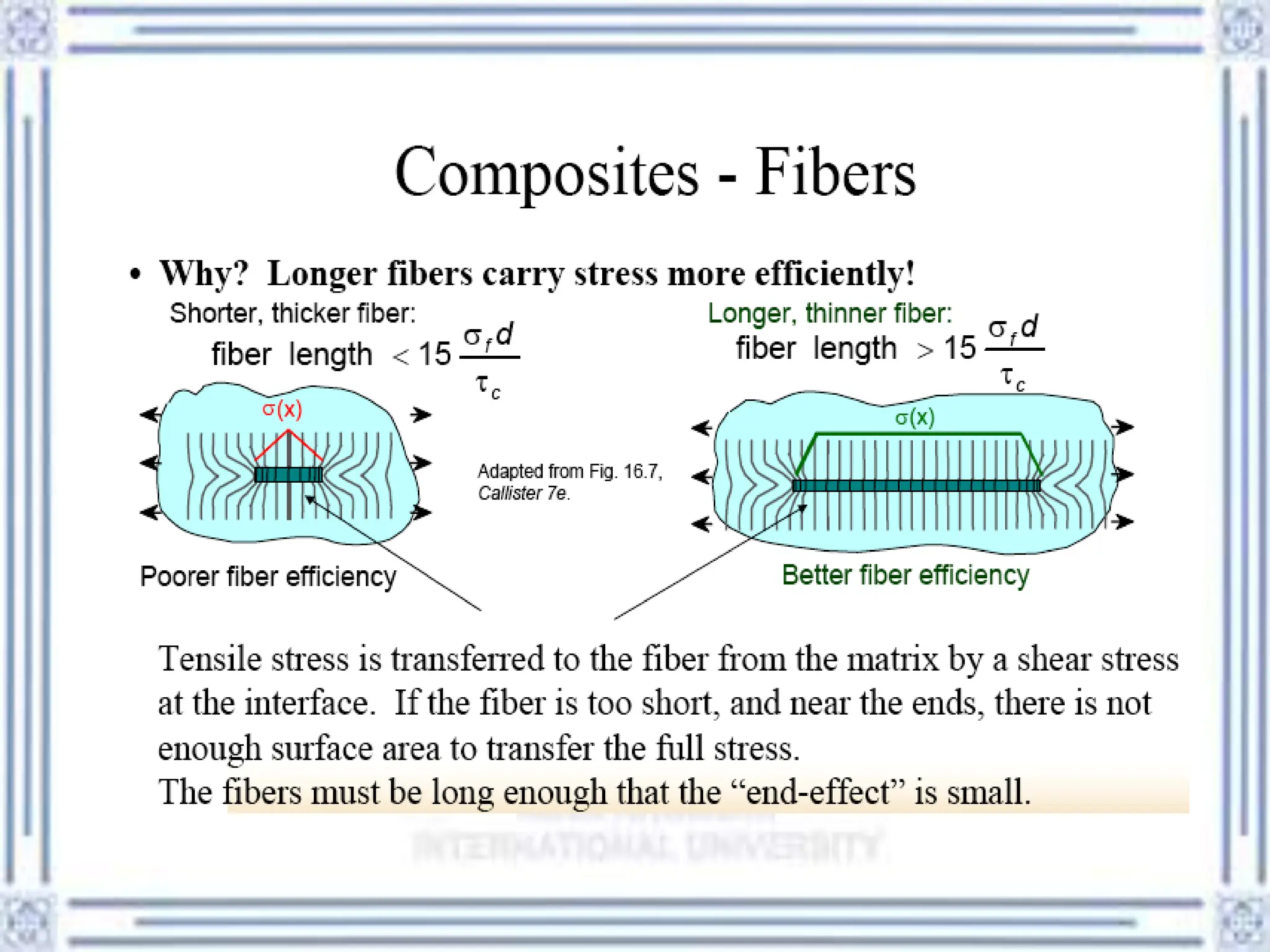

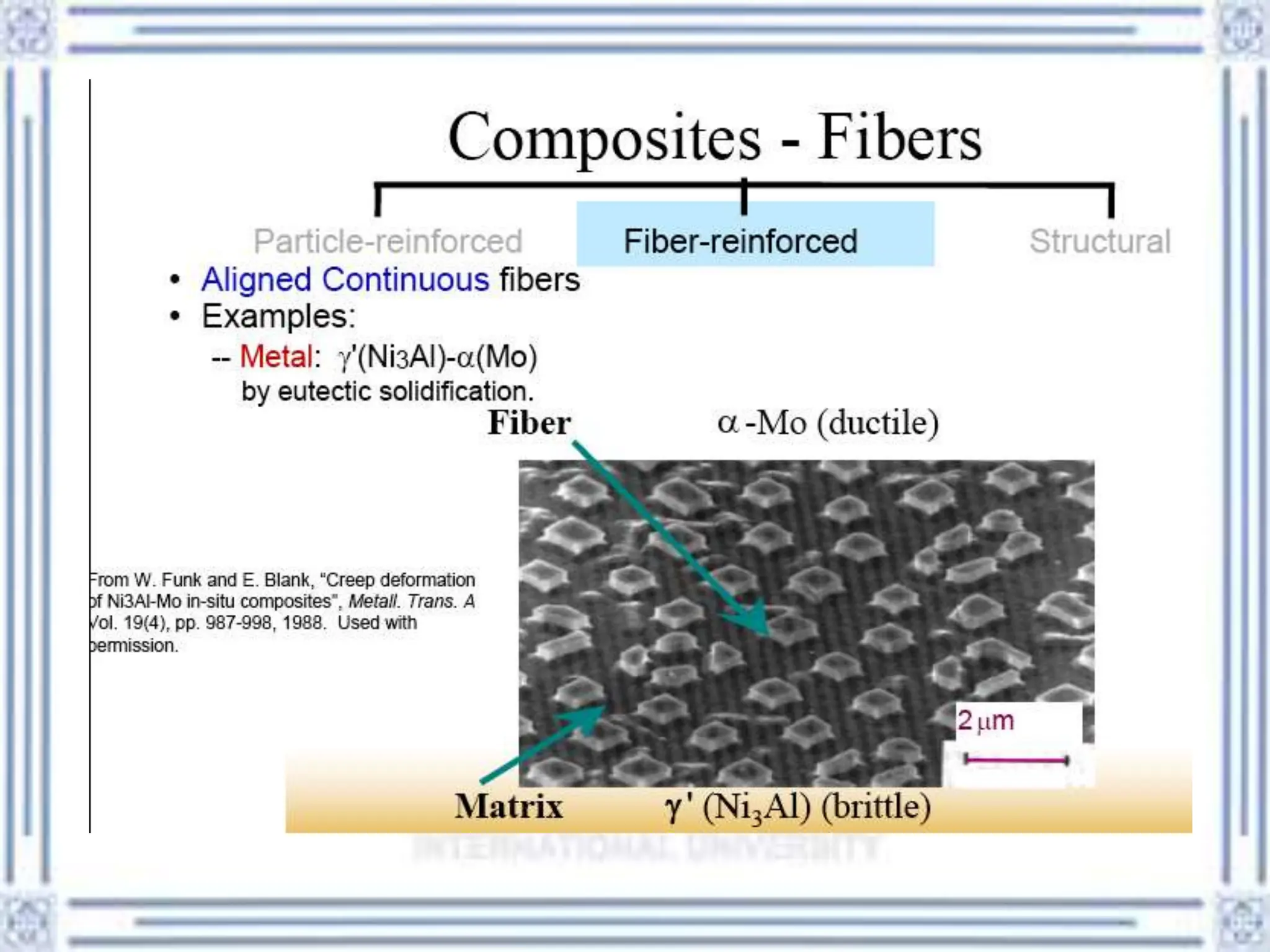

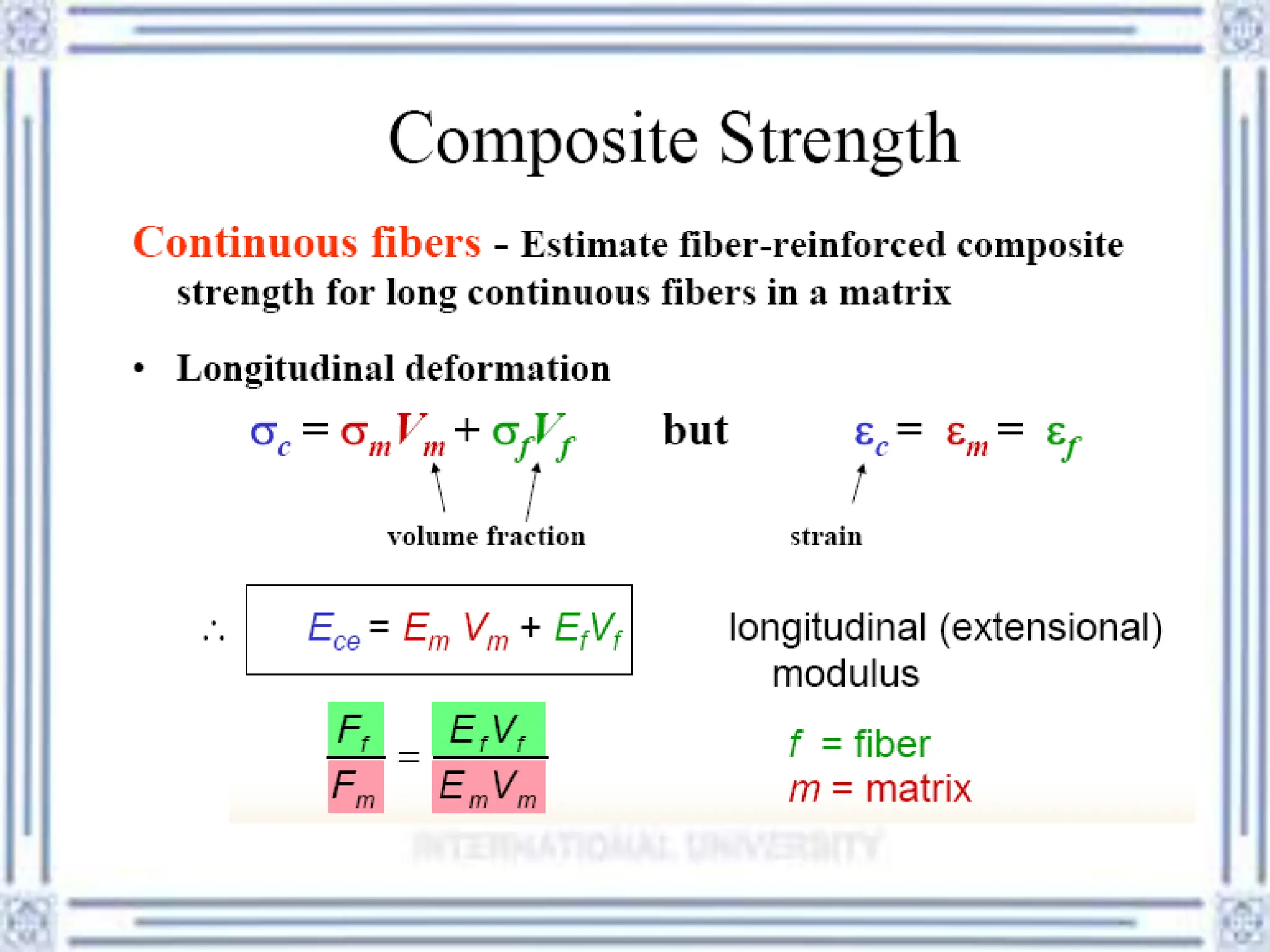

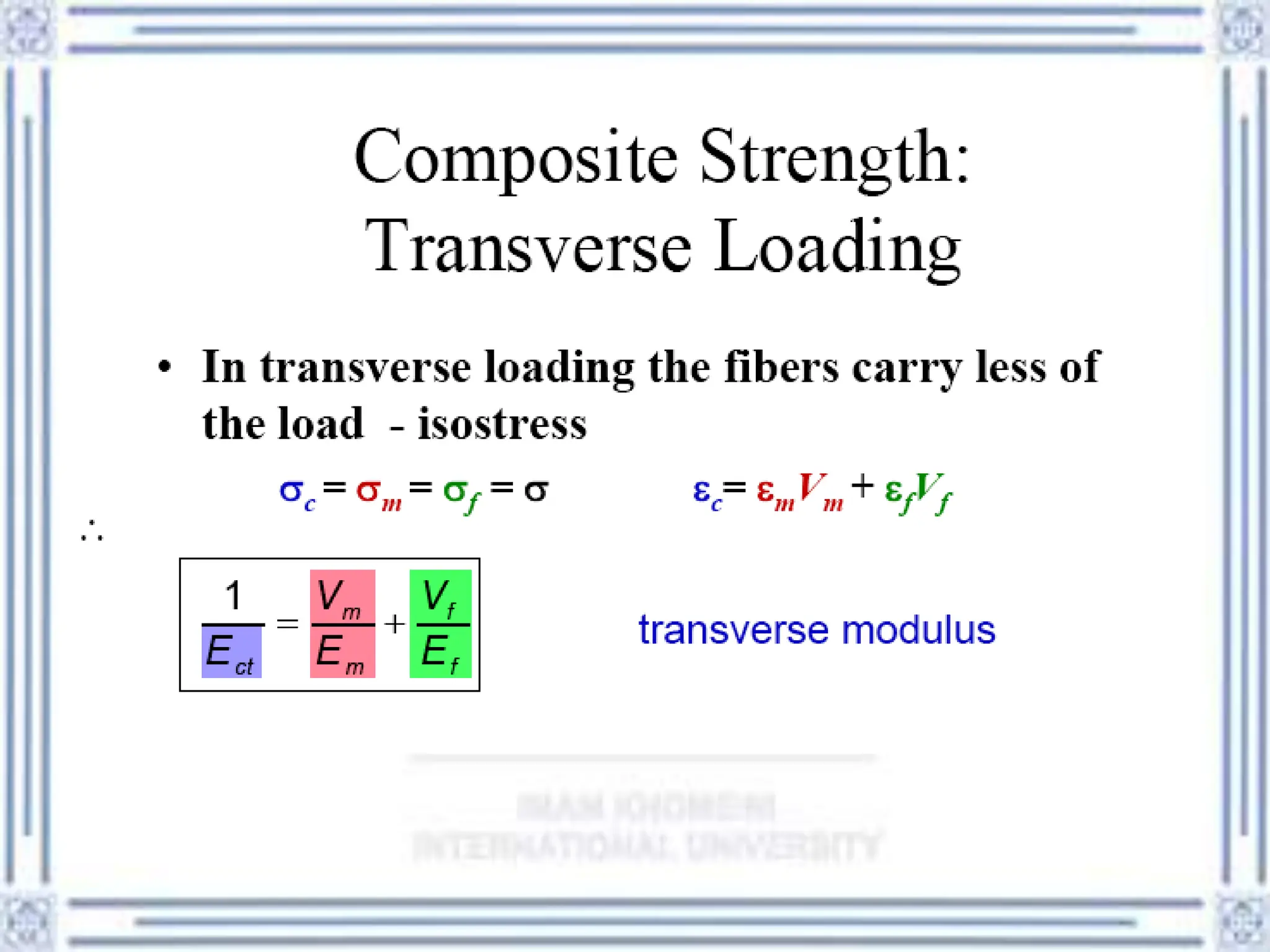

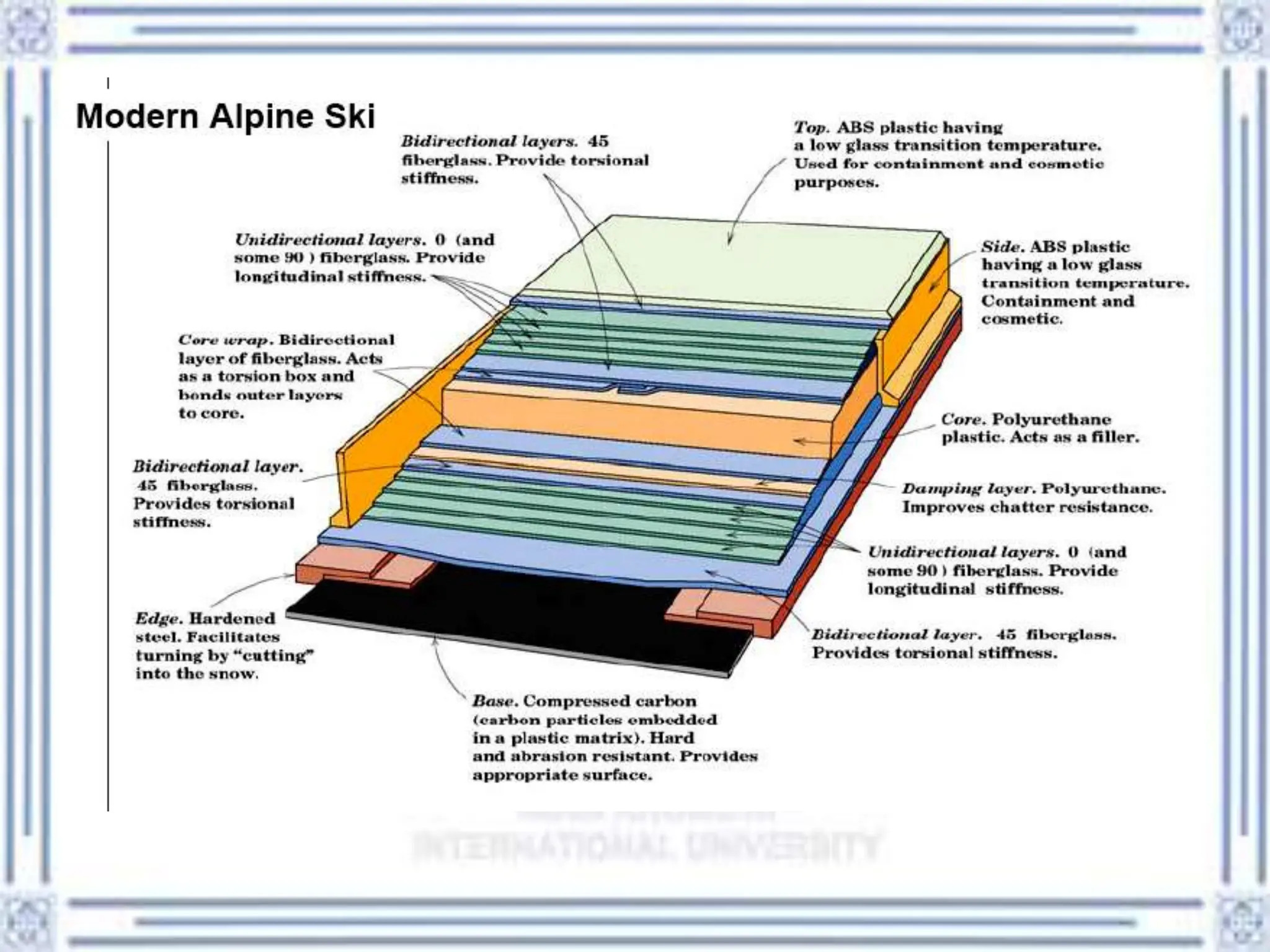

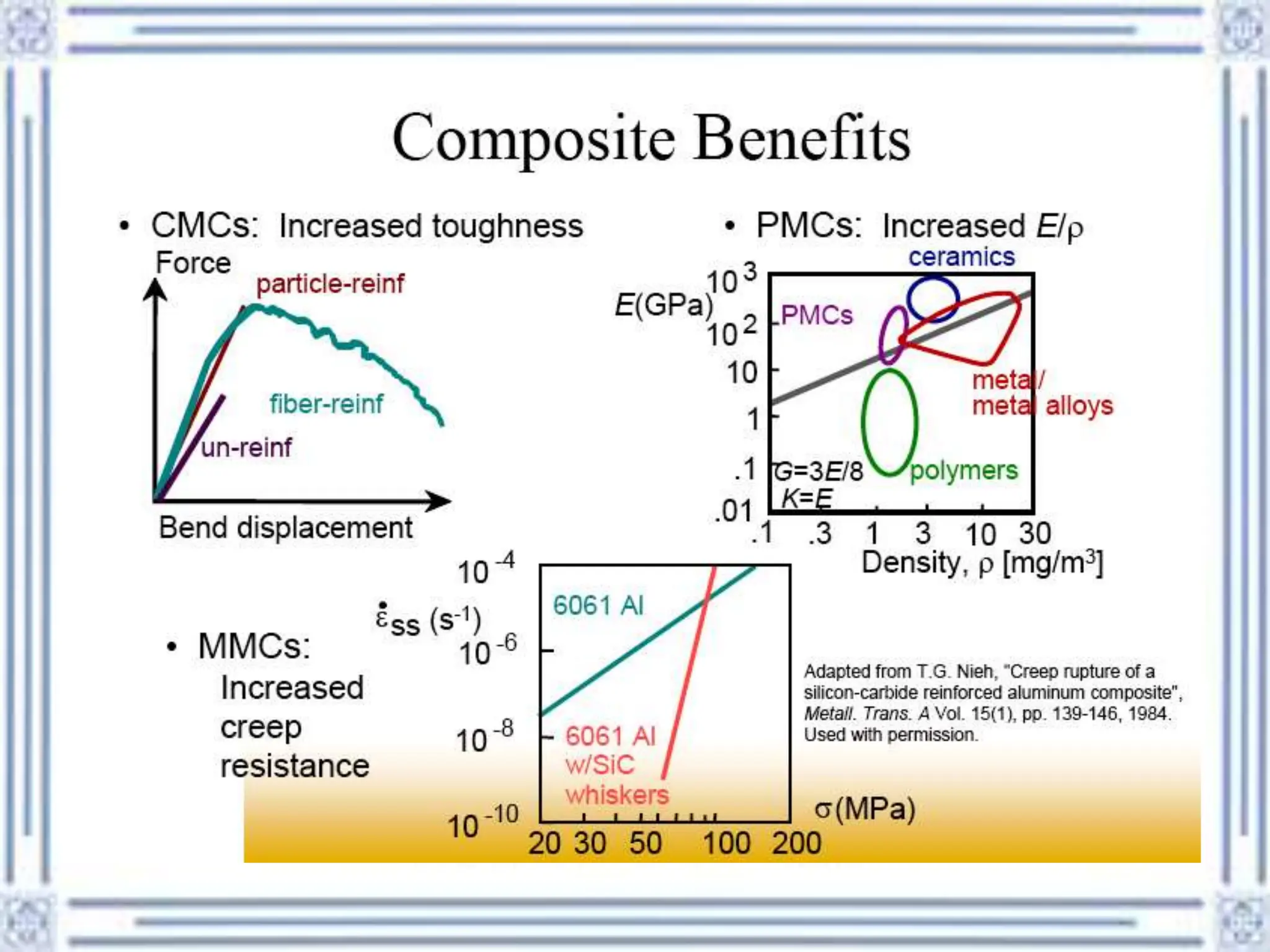

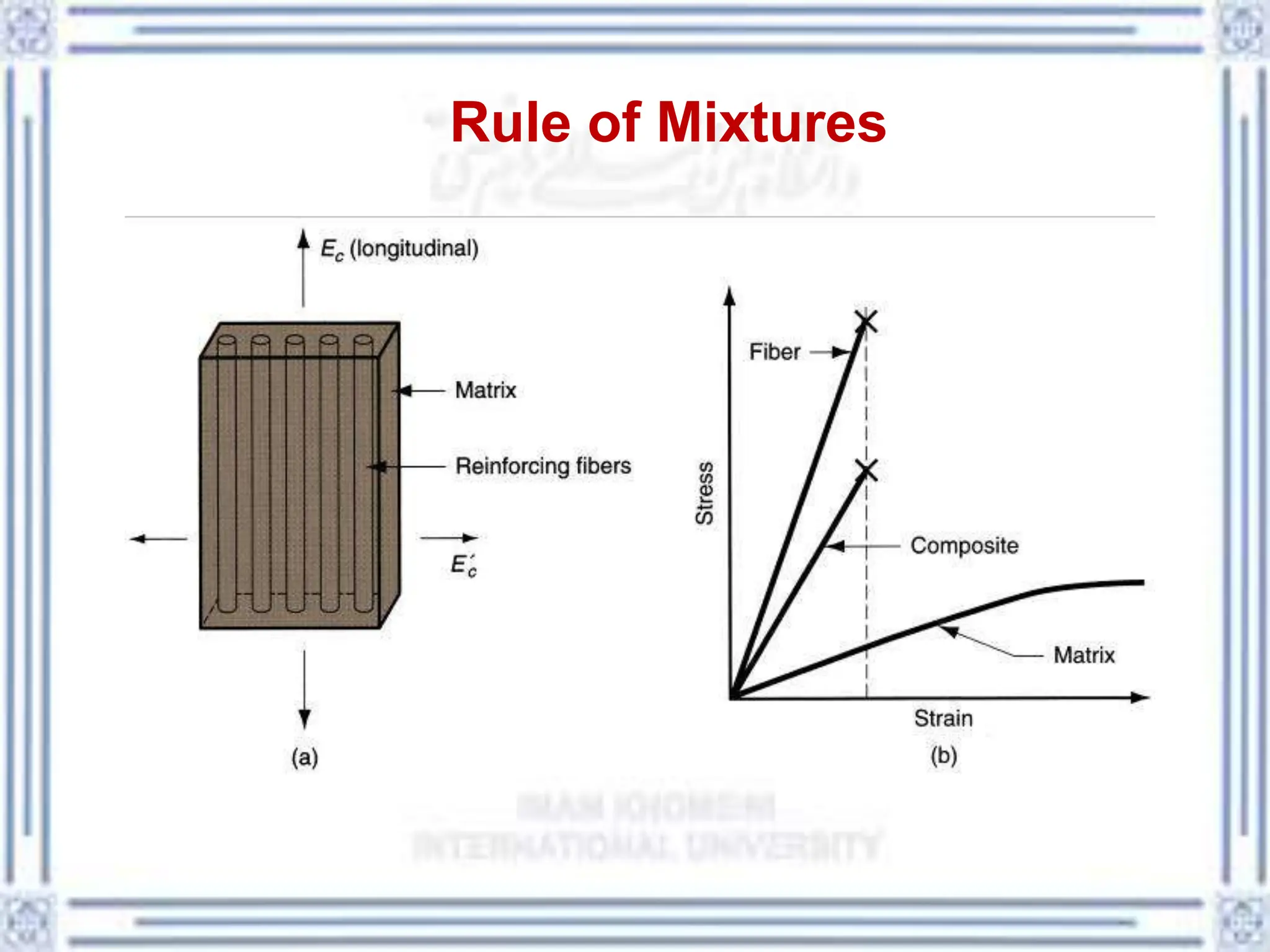

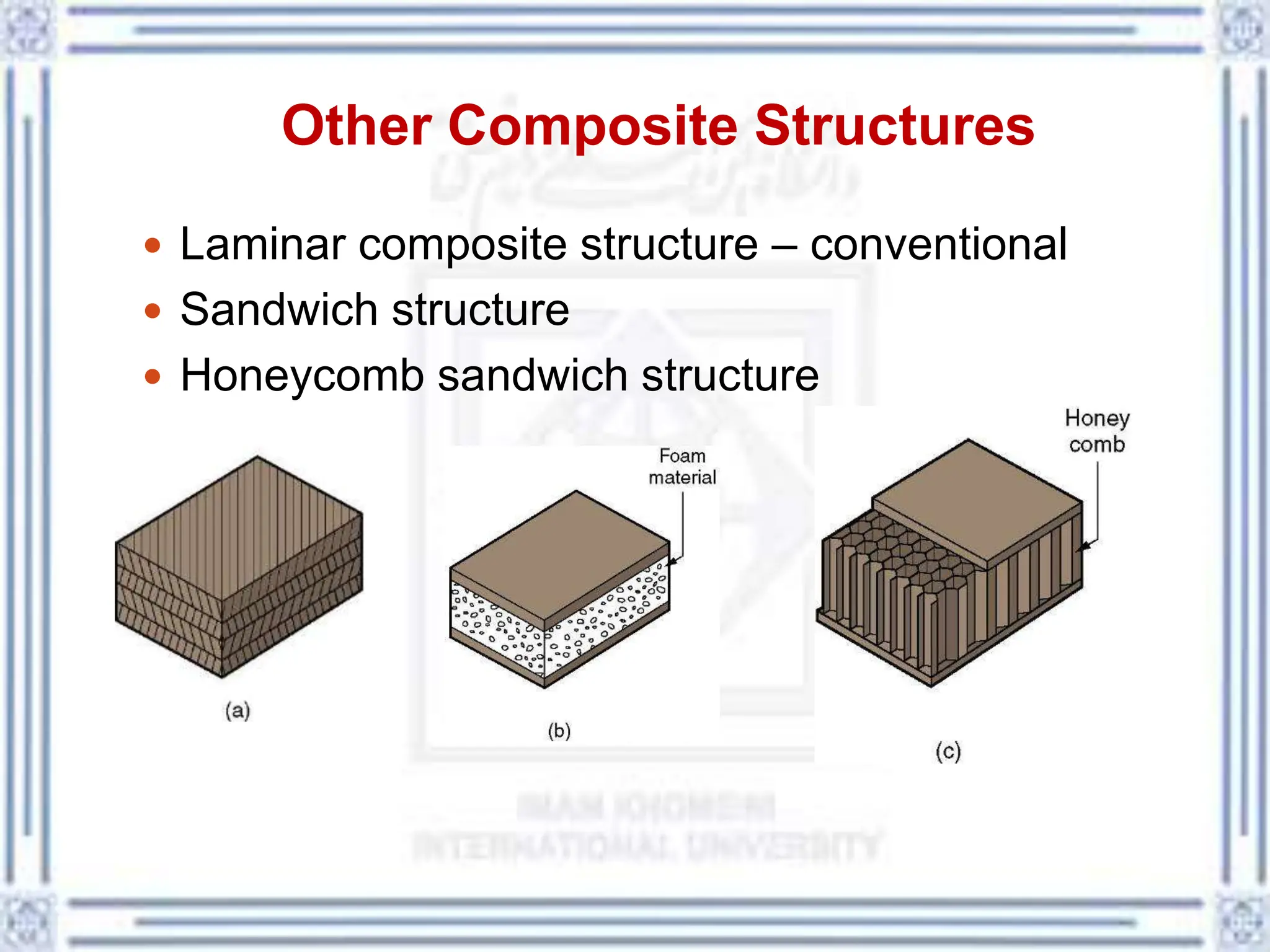

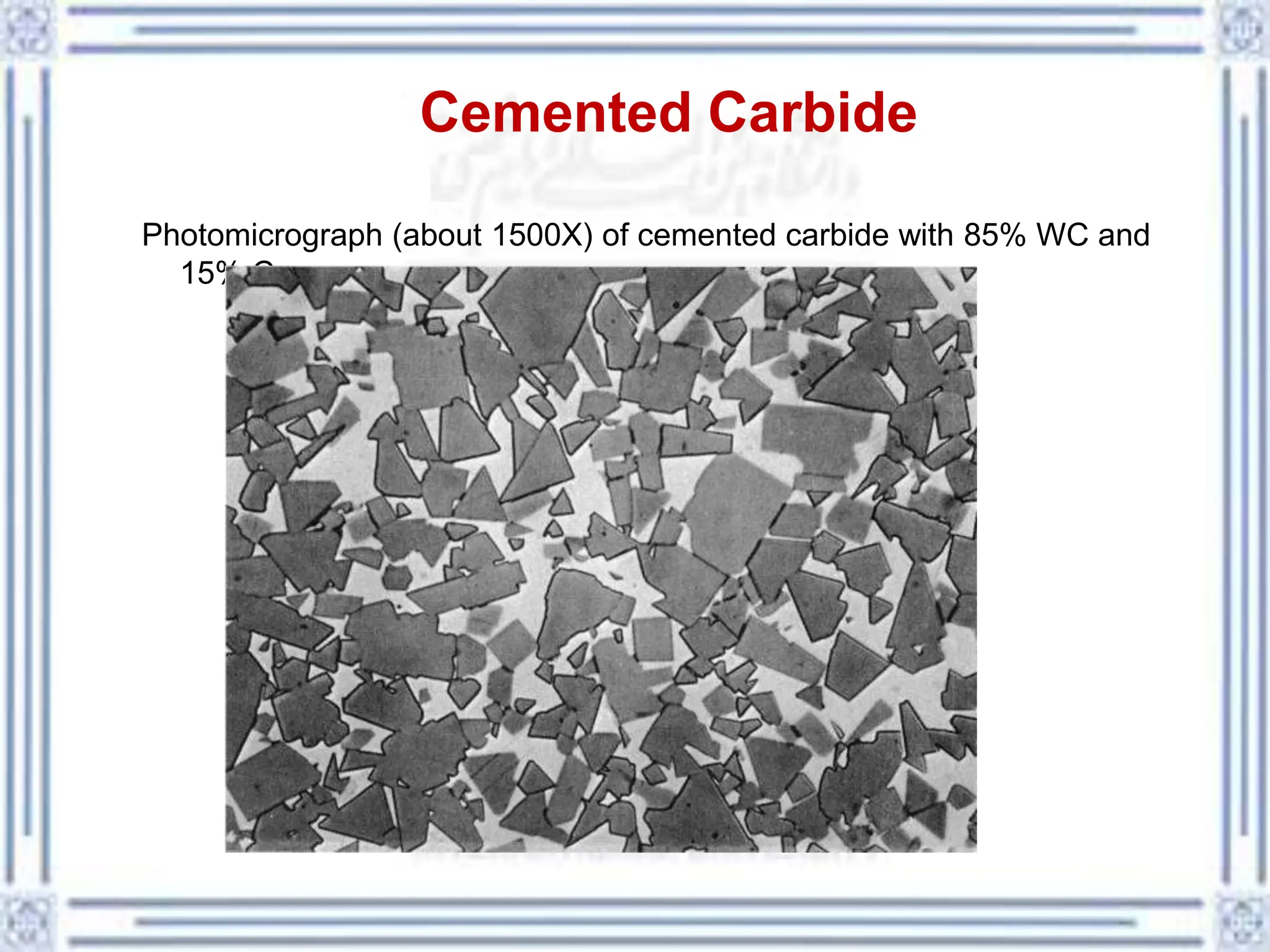

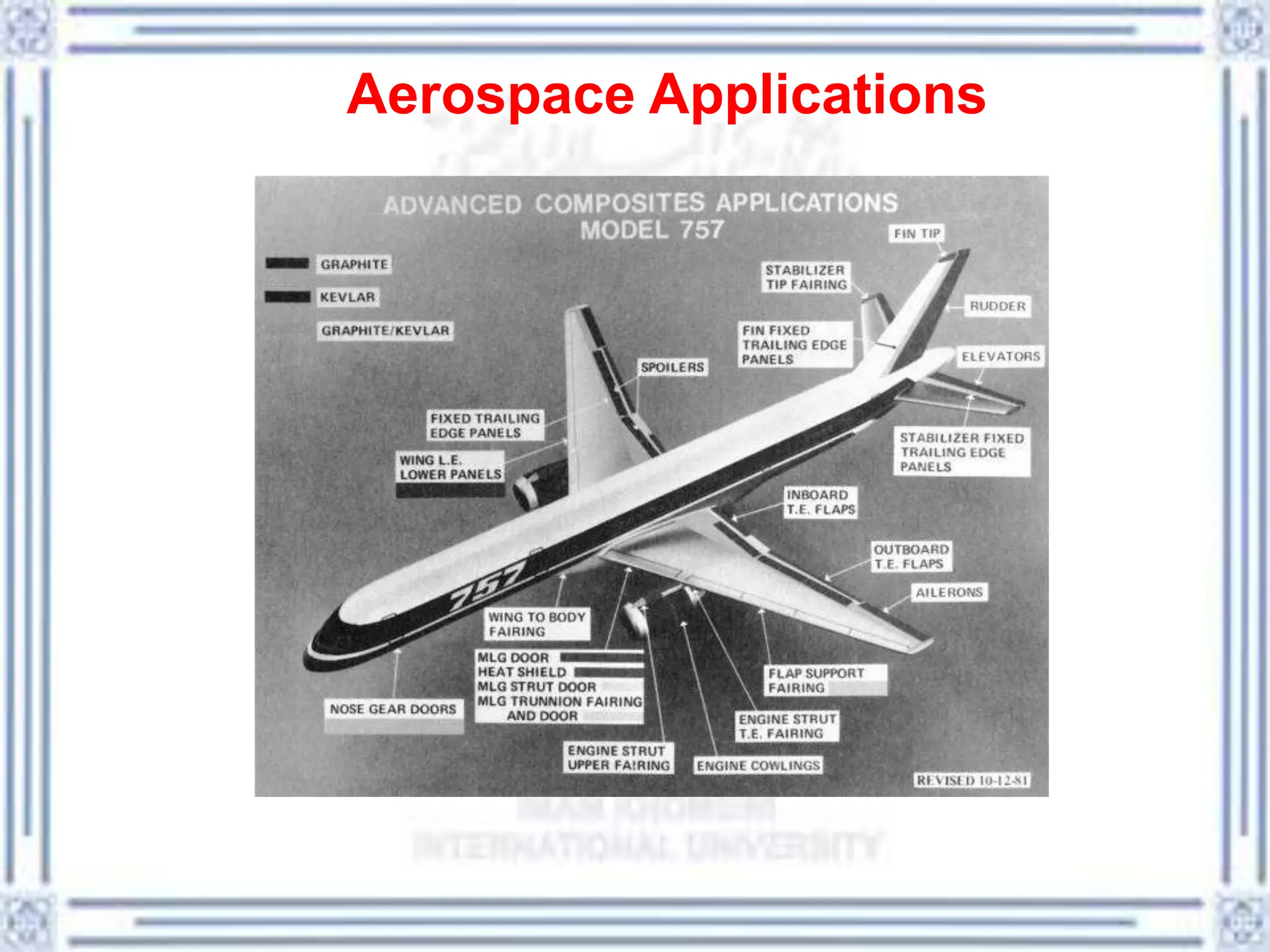

This document provides an overview of composite materials. It defines a composite as a material made of two or more physically distinct phases that produce properties different from the individual components. The document discusses various types of composite materials, including metal matrix composites, ceramic matrix composites, and polymer matrix composites. It also covers the classification of composites, functions of the matrix, reinforcing phases, properties, processing techniques, and applications.