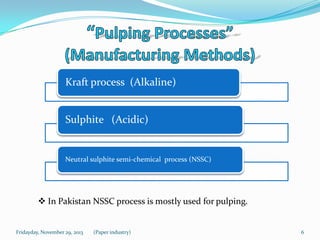

The document provides an overview of paper manufacturing, covering its definition, historical origins, and the processes involved in its production, including raw material preparation, digestion, bleaching, and the paper-making machine. It also discusses recycling, environmental impacts, and provides statistical data on paper usage and production in Pakistan, including major paper mills in the country. The paper industry is highlighted for its contributions and challenges related to deforestation, air, and water pollution.