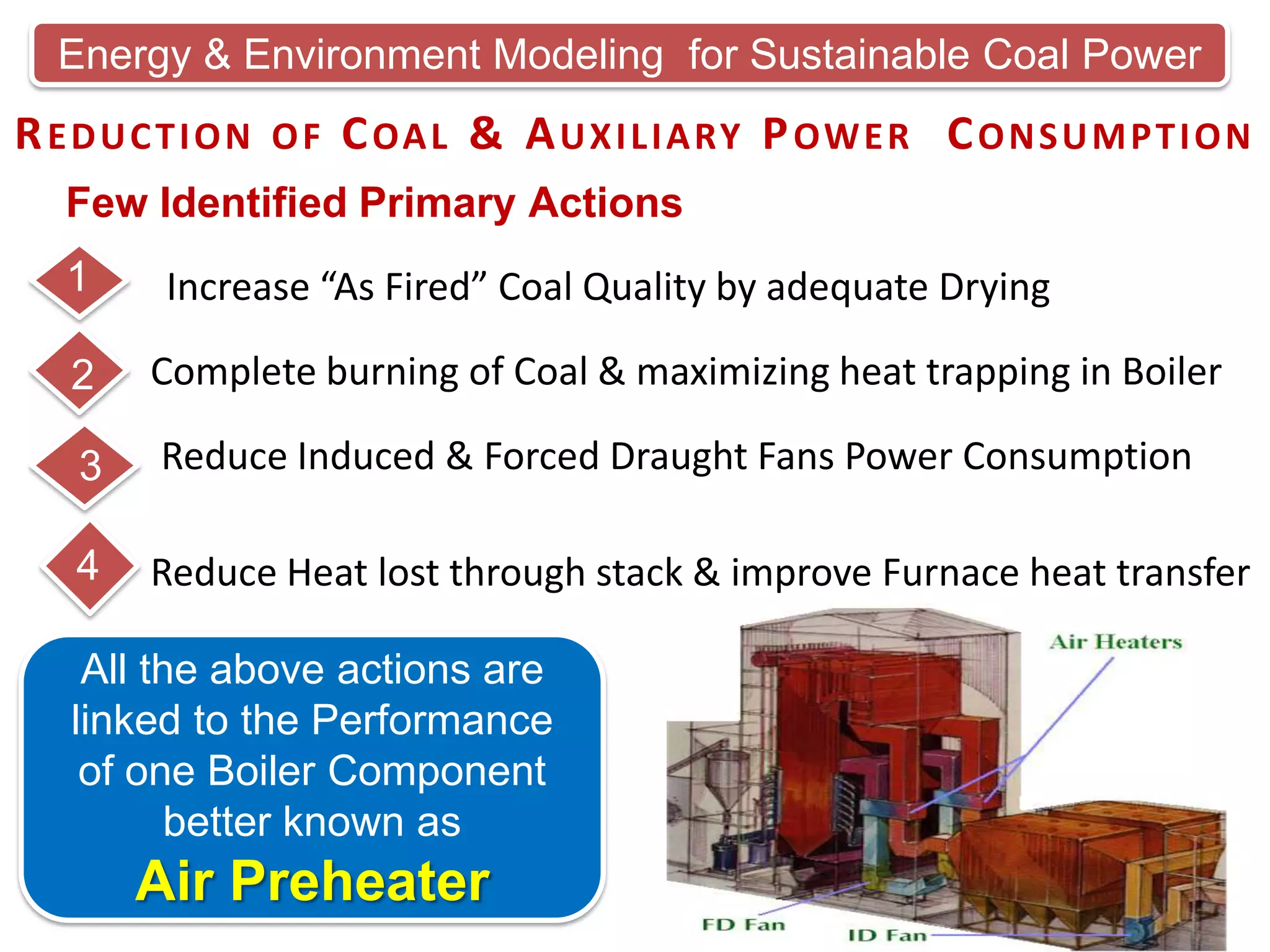

This document summarizes research on the effect of ambient air temperature on the performance of regenerative air preheaters used in pulverized coal-fired boilers. The summary is:

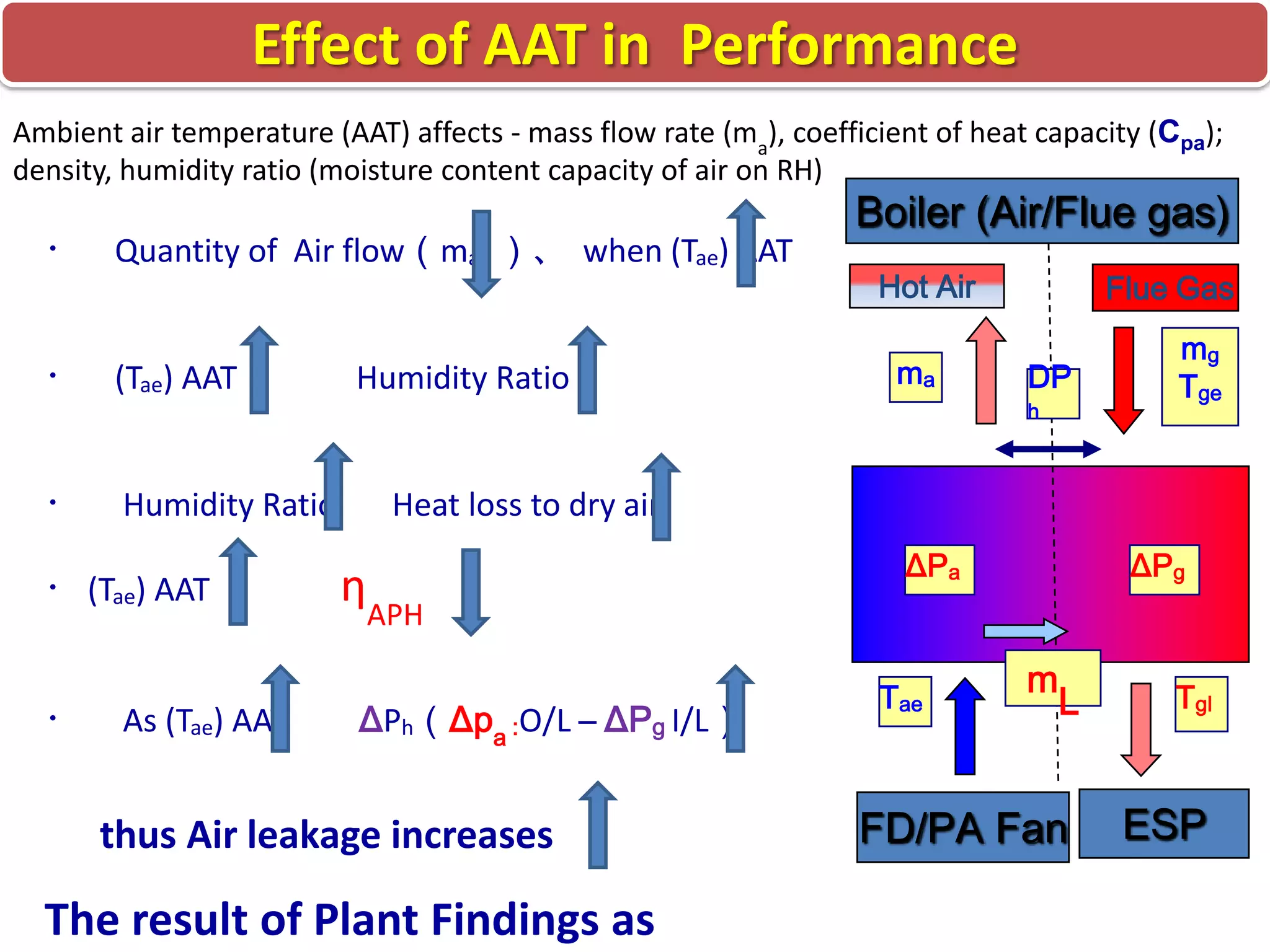

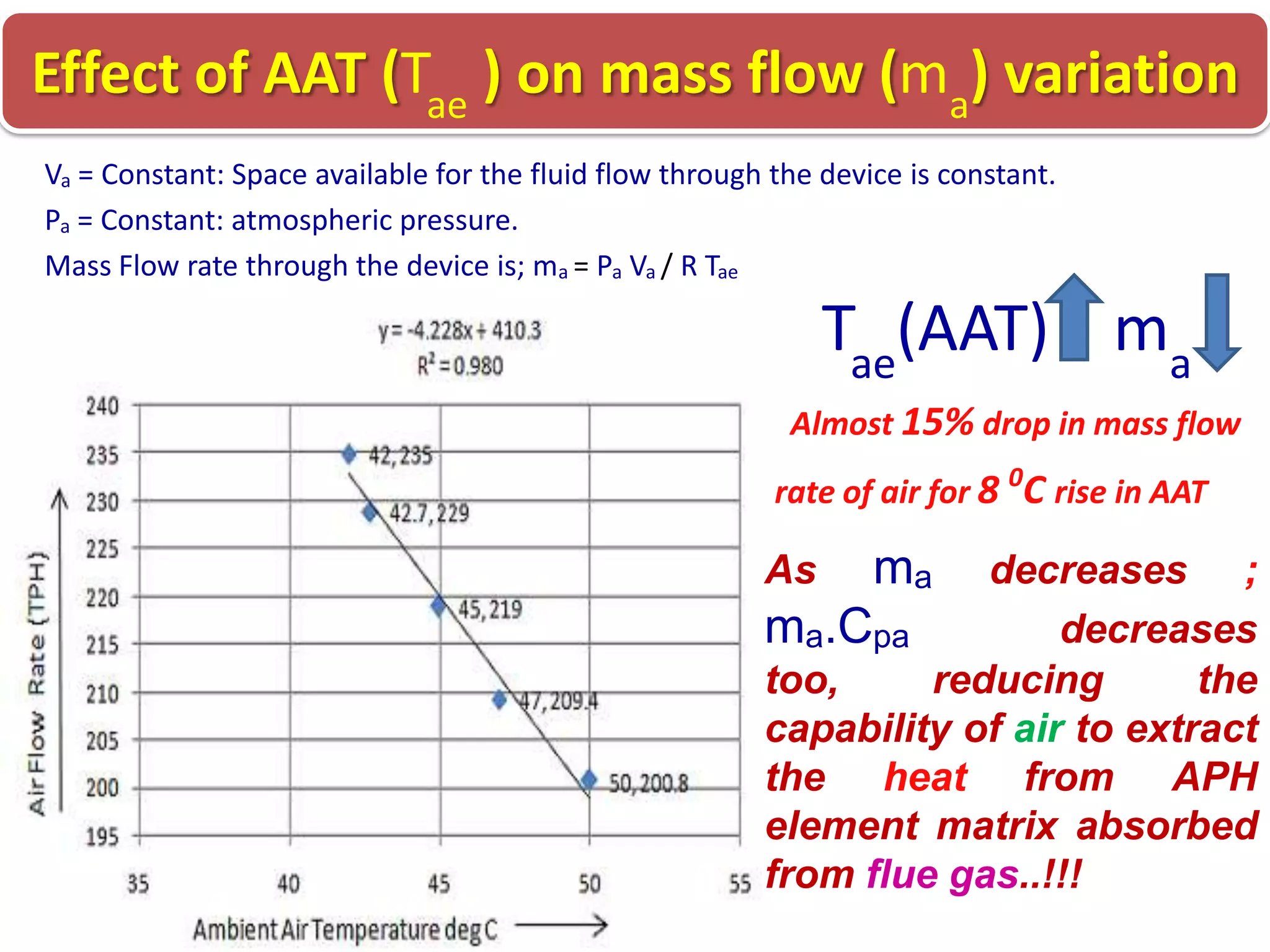

1) Ambient air temperature affects the mass flow rate and heat capacity of air entering the preheater, reducing its ability to extract heat from flue gases.

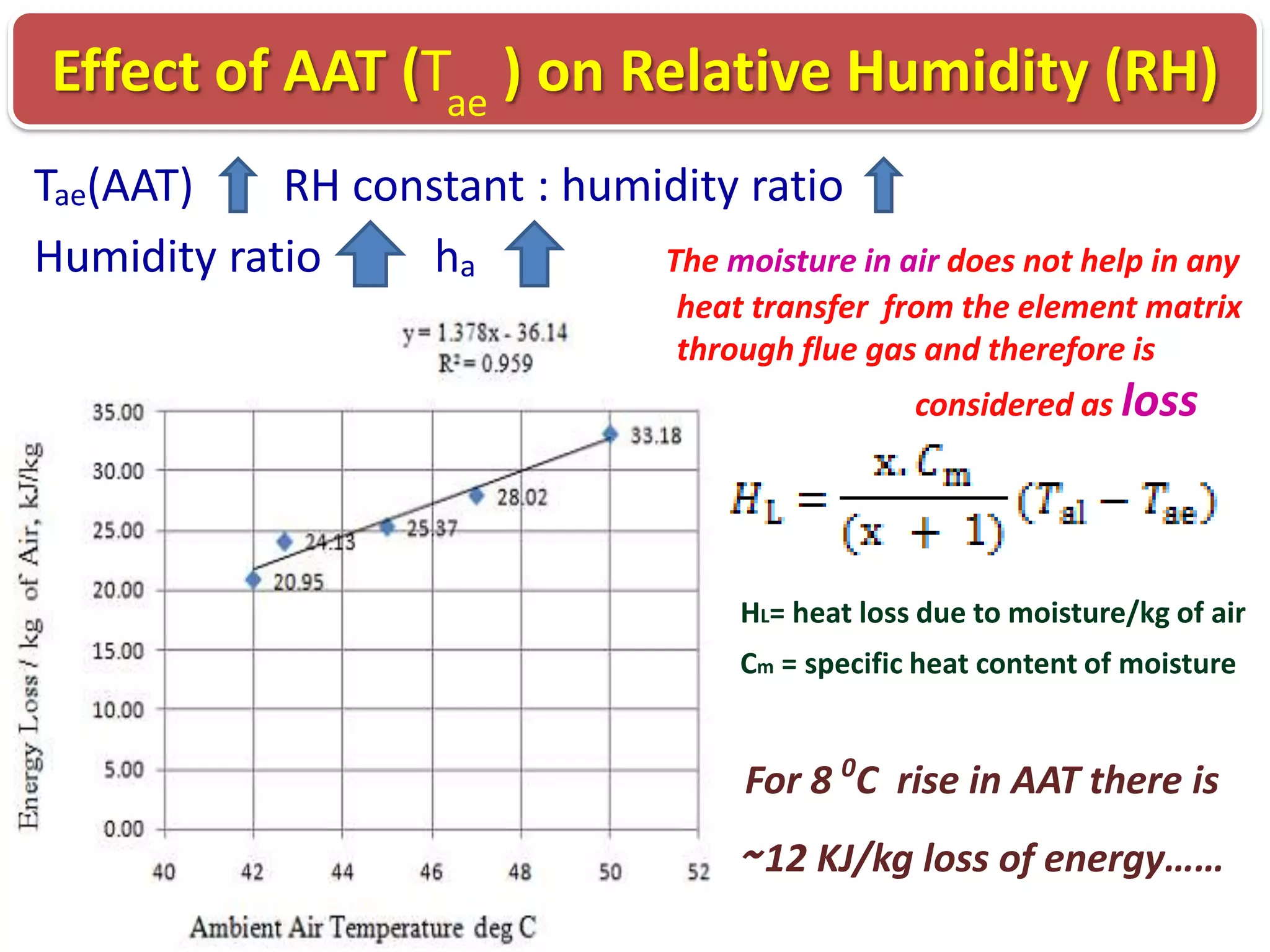

2) Higher ambient temperatures also increase the humidity ratio of air, resulting in heat losses from moisture that do not contribute to heat transfer.

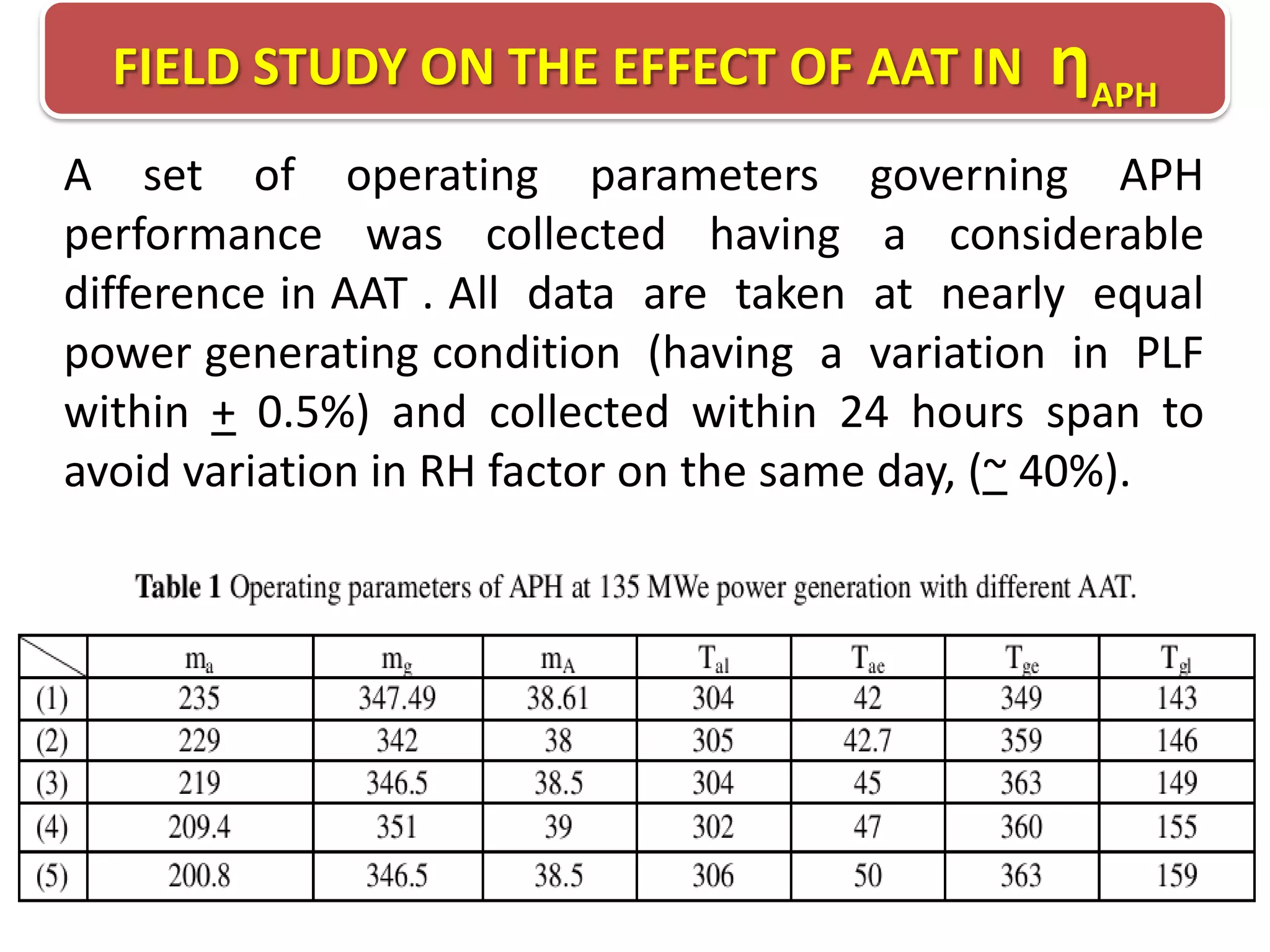

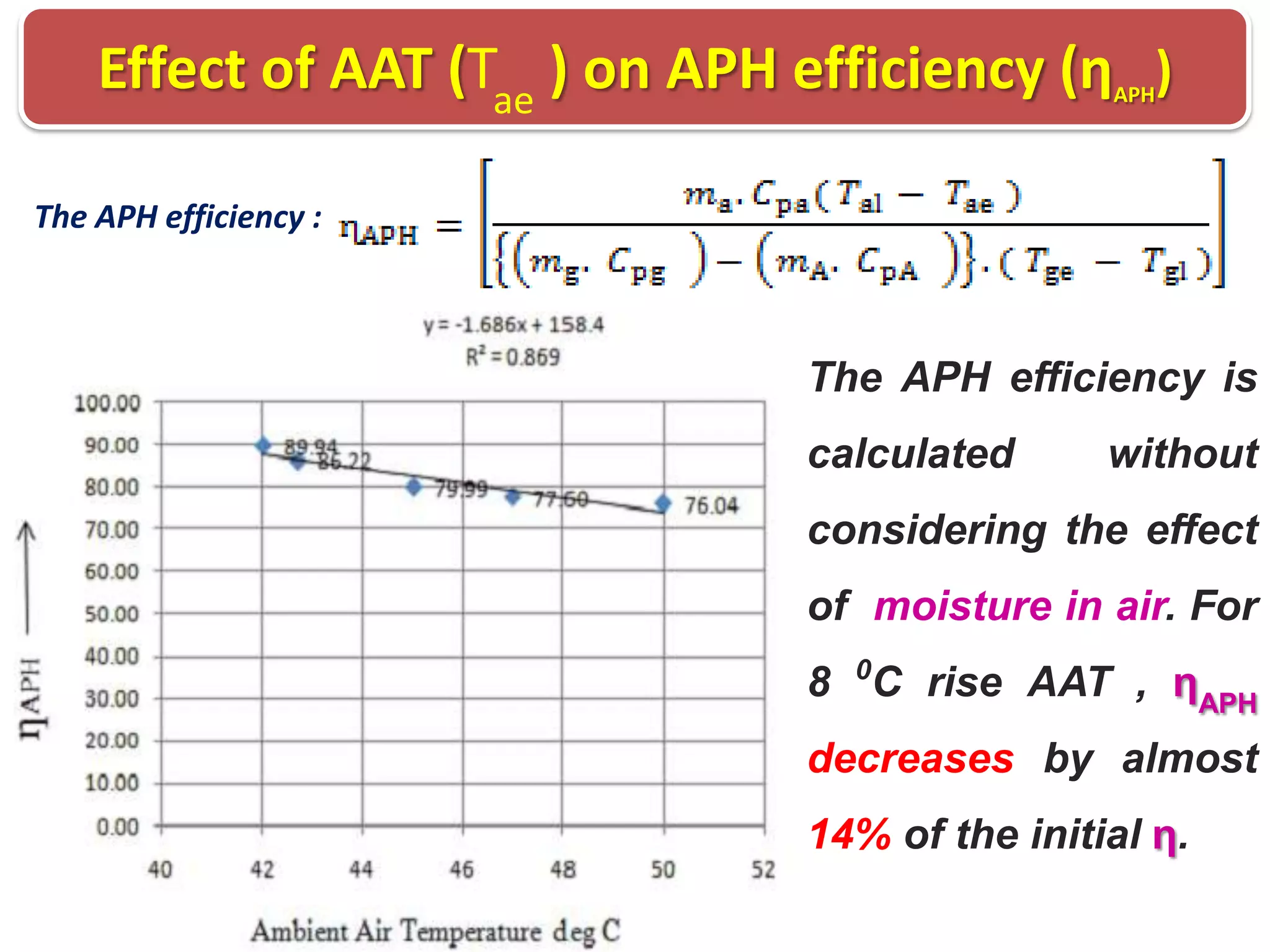

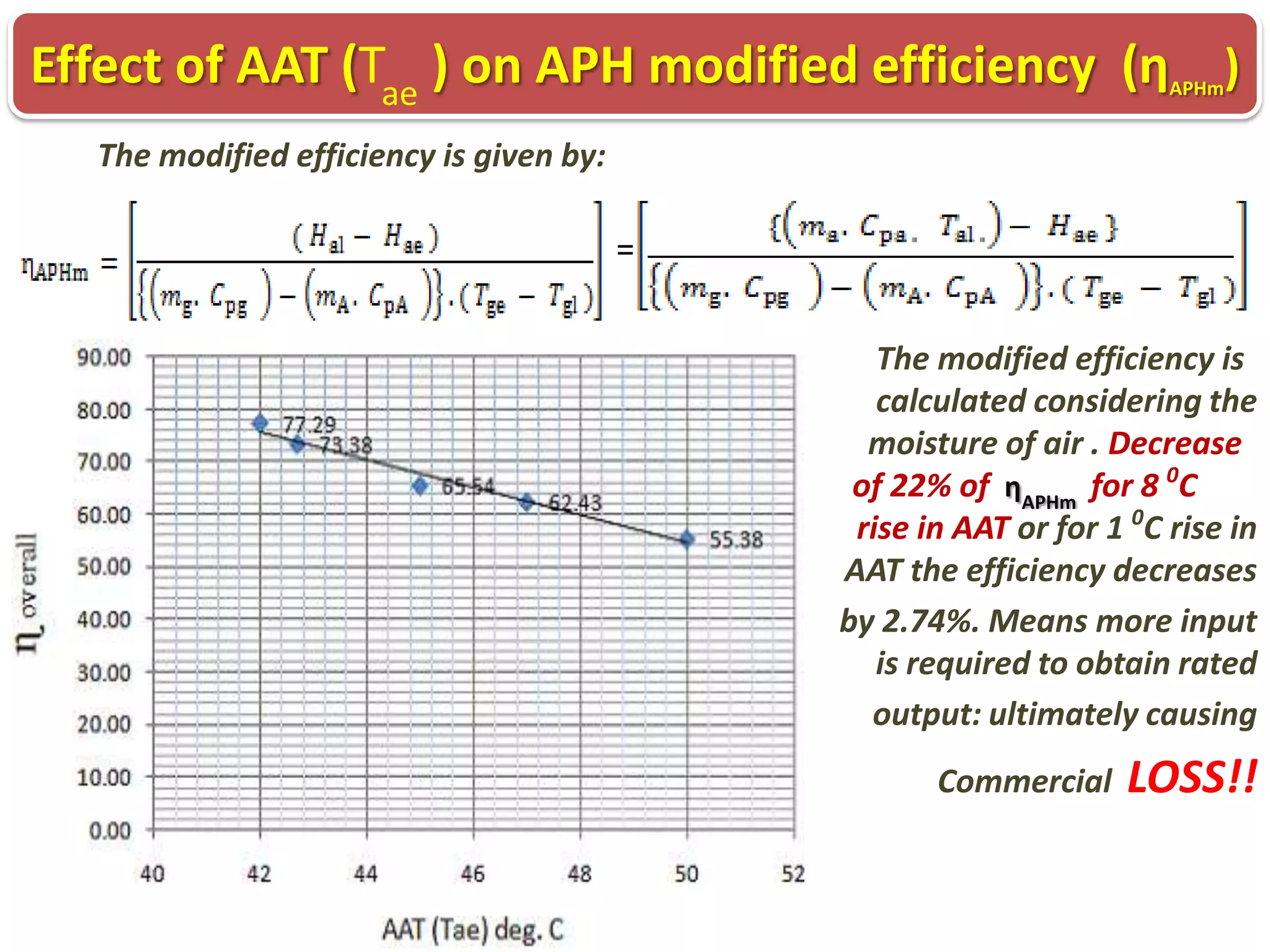

3) Field studies showed regenerative air preheater efficiency decreases by around 14% for an 8°C rise in ambient temperature, and modified efficiency that accounts for moisture decreases by 22% for the same temperature rise

![APH Heat Exchange Performance Evaluation

Regenerative APH Heat Exchange Mechanism

Hot side

Heating Surface

On Rotation Heating Surface

Flue Gas H/E

Storage H/E

Flue Gas & Air Side Heat Balance

Heat Transferred by Flue Gas qg:

1.

qg = mge x Cpg x (TgeTgl)

Cold side

Heating Surface

Transfer H/E in Air

Air Leaving

Tal

mal

qal

Gas Entry

qge

+Qa

Tge

mge

Heat Transferred to Air qa:

2.

qa = mal x Cpa x (Tal- Tae)

+Qa

- Qg

qae

- Qg

qgl

m : Mass of Fluid [ Flue Gas / Air ] (kg/h)

Cp: Mean Specific Heat between Tae and Tgl (kcal/kg

/℃)

T : Temperature of Hot/Cold Fluid [ Flue Gas / Air ] (℃)

Heat Balance: qg = qa

mgex Cpg x (Tge- Tgl) = mal x Cpa x (Tal-

Tae

Air Entry

Tgl

Gas Leaving](https://image.slidesharecdn.com/paper11icaer2013modified-131211043945-phpapp02/75/Paper-11-icaer_2013modified-9-2048.jpg)