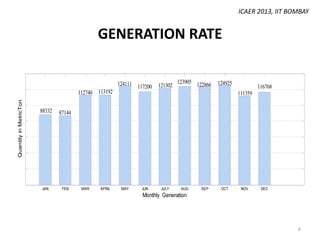

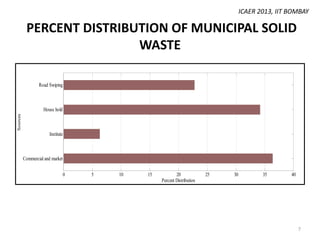

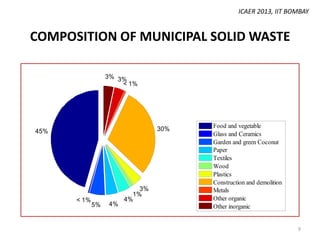

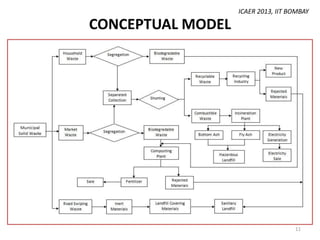

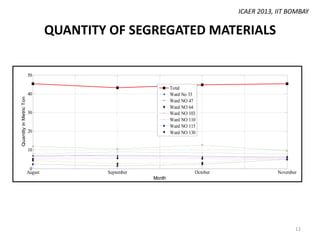

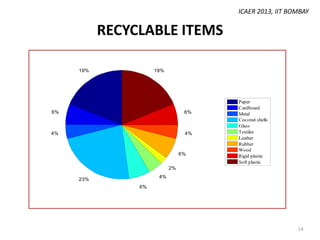

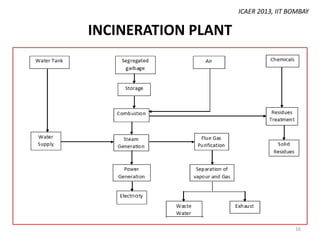

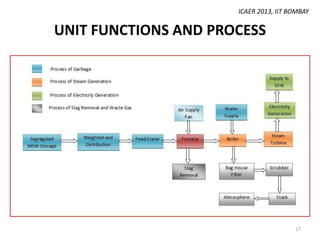

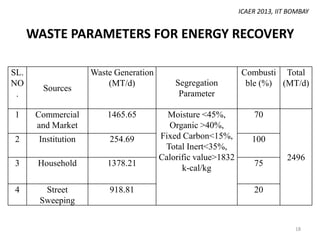

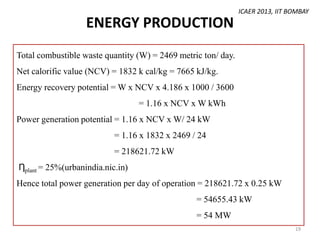

This document summarizes a presentation given at ICAER 2013 at IIT Bombay about classifying and generating energy from municipal solid waste in Kolkata, India. It discusses how waste is generated and composed, methods to recover recyclable materials, waste-to-energy techniques like incineration, and landfill precautions. Specifics included are that over 2469 metric tons of waste can be burned daily to generate over 54 megawatts of power, and integrated waste management is needed to reduce landfilling and reuse materials. The presentation outlines municipal waste issues in Kolkata and solutions for improved management and energy recovery.