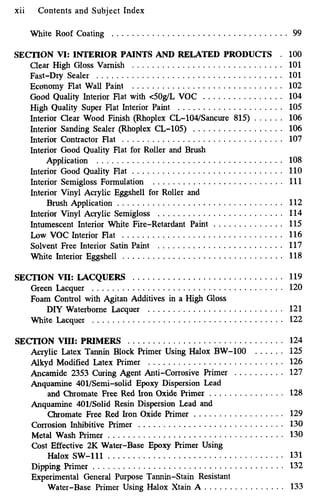

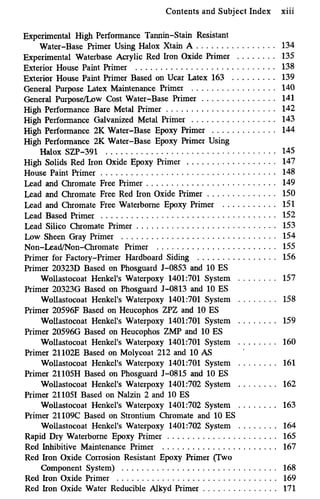

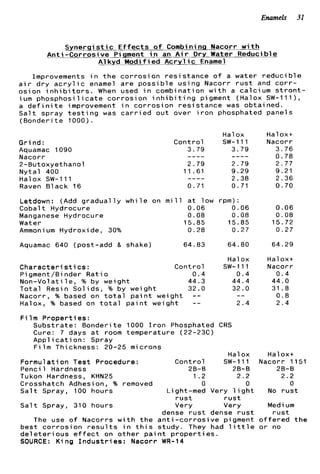

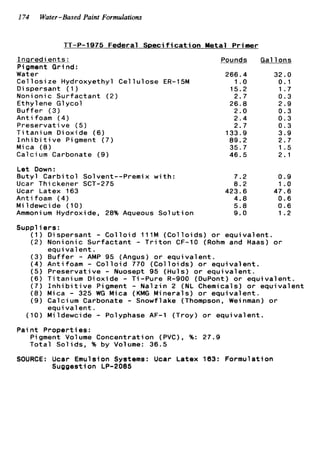

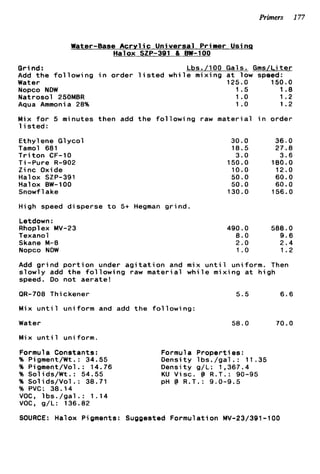

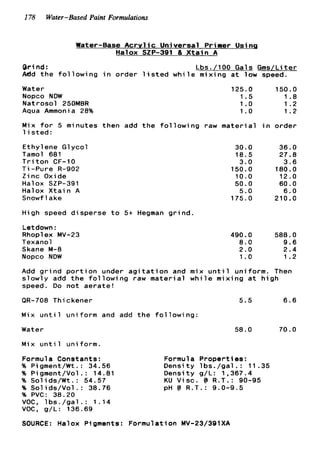

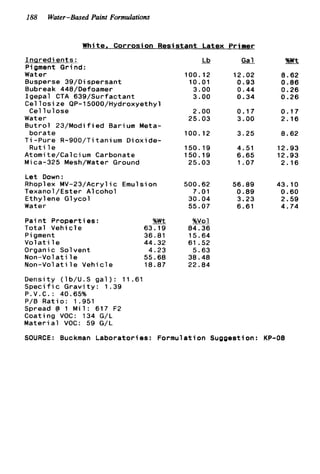

This document provides 232 water-based paint formulations organized into 11 sections. It includes an introduction describing the purpose and organization of the book. The formulations are for various coatings, topcoats, enamels, primers, and other paint types. Product properties are provided where available. The book is a useful reference for those in the paint industry and others interested in water-based and environmentally safer formulations.

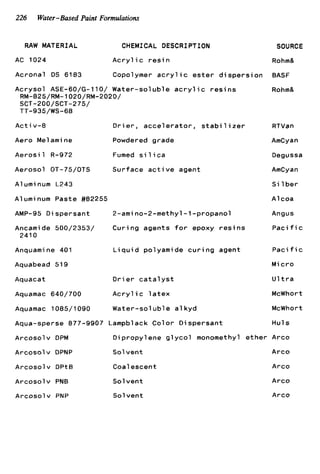

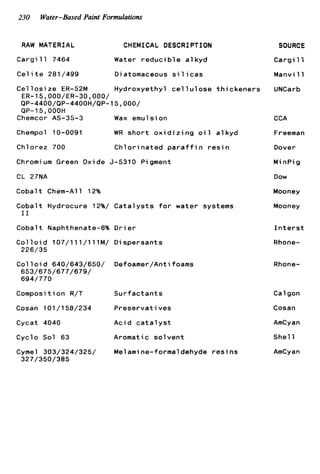

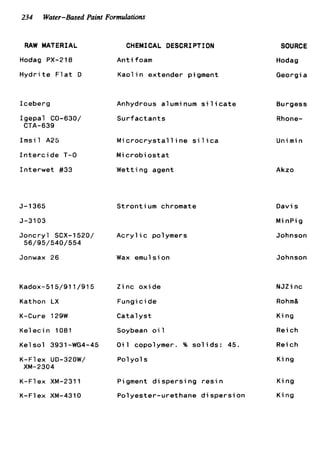

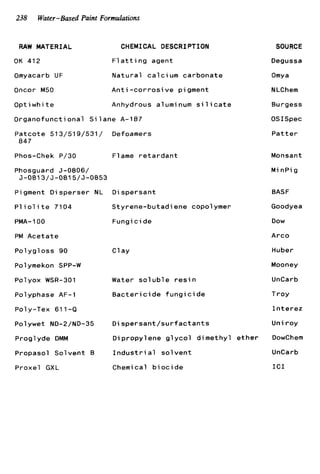

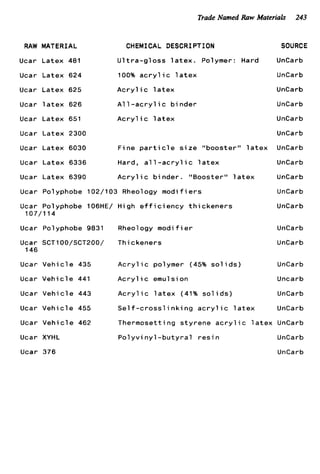

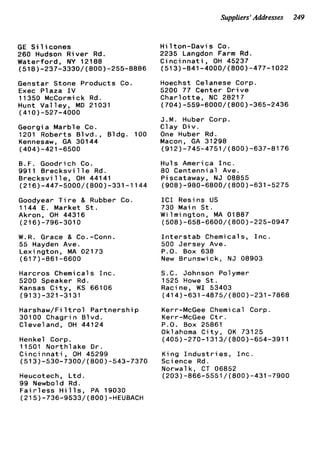

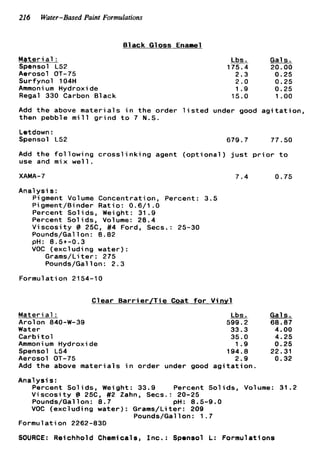

![Miscellaneous 217

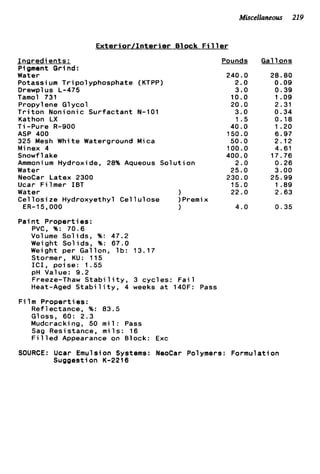

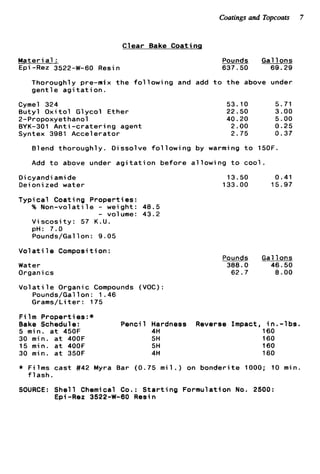

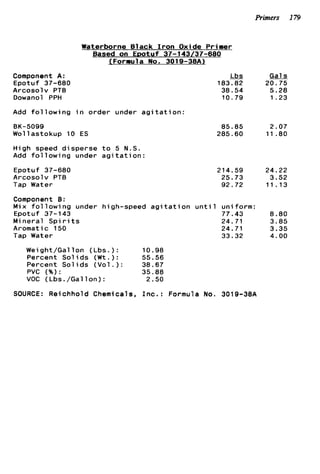

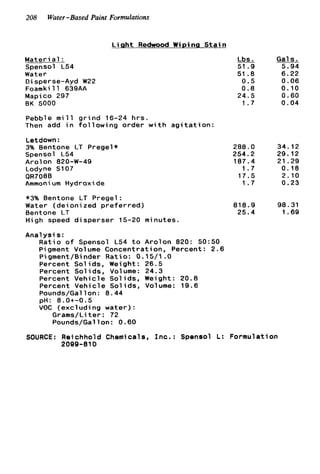

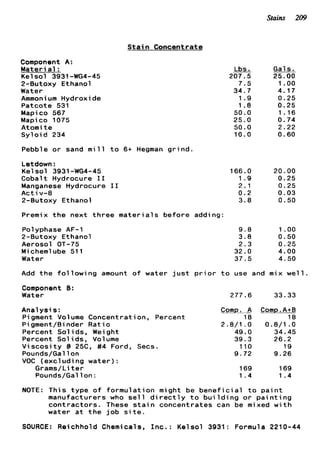

Clear T i n t Base

M a t e r i a l :

Kels o l 3931-WG4-45

Strodex P-1 00

I n t e r c ide T-0

Lbs. Gals.

370.0 44.52

1.6 0.19

4.2 0.43

Premix t h e next t h r e e m a t e r i a l s i n order, then add under good

a g i t a t i o n :

Act iv-8

Cobalt Hydrocure I1

Manganese Hydrocure

Add t h e f o l l o w i n g i n order:

Polymekon SPP-W

Polyphase AFl

Water

Ammoni um Hydroxi de

Analysis:

Percent Solids, Weight: 23.3

2.1 0.36

1.3 0.17

5 . 0 0.66

33.3 4.16

8.4 0 . 8 1

405.9 48.73

0 . 5 0.07

Percent S o l i d s ] Volume: 21.6 (approx)

V i s c o s i t y @ 25C, #2 Zahn, Secs.: 20-25

VOC (excluding water):

Grams/Li t e r : 185

Pounds/Gal 1on : 1 .54

pH: 8.2-8.6

SOURCE: Reichhold Chemicals, I n c . : Kelsol 3931: Formula 2099-32](https://image.slidesharecdn.com/water-basedpaintformulationsvol-150102090547-conversion-gate02/85/Water-based-paint-formulations-Vol-4-218-320.jpg)