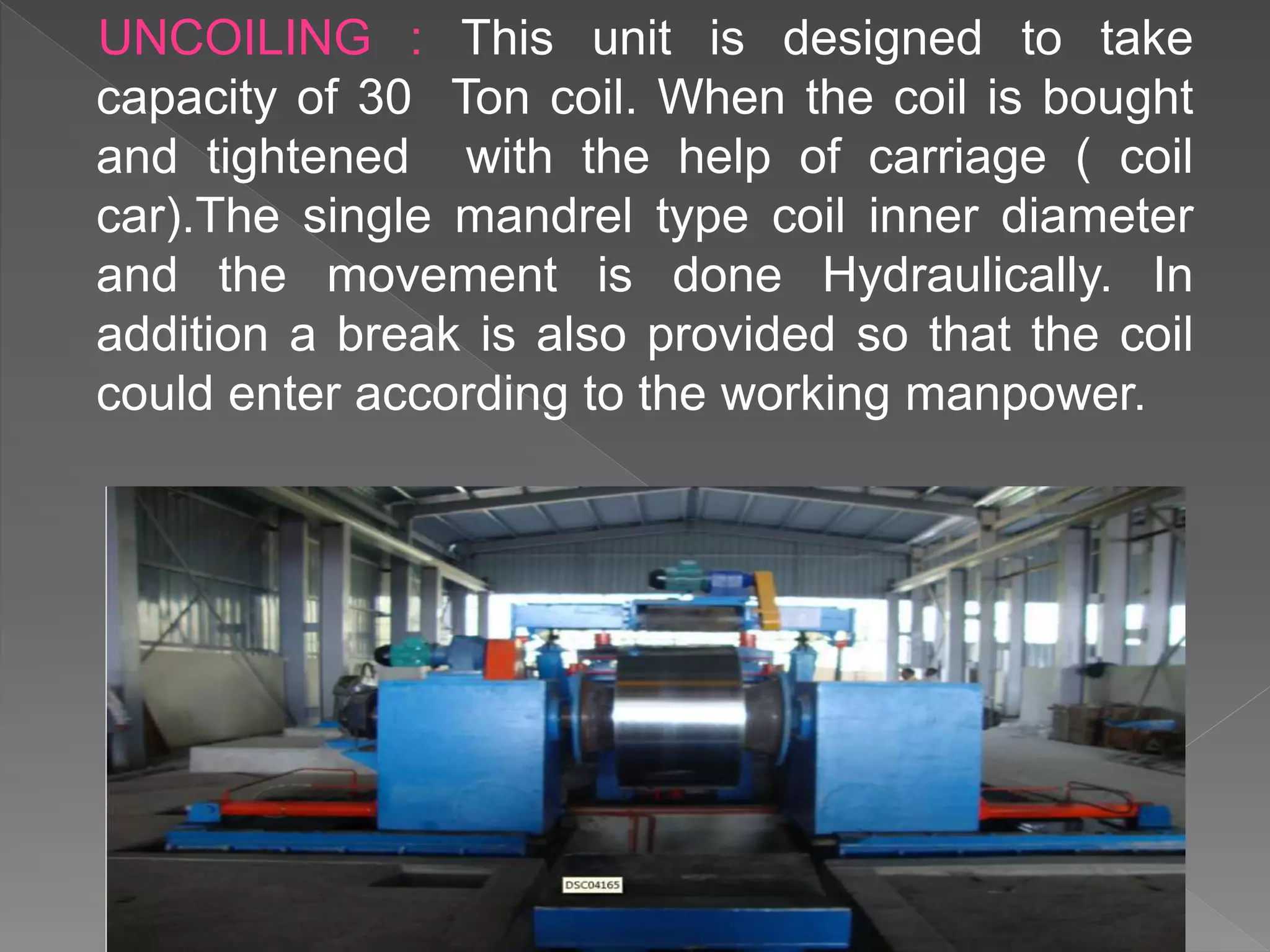

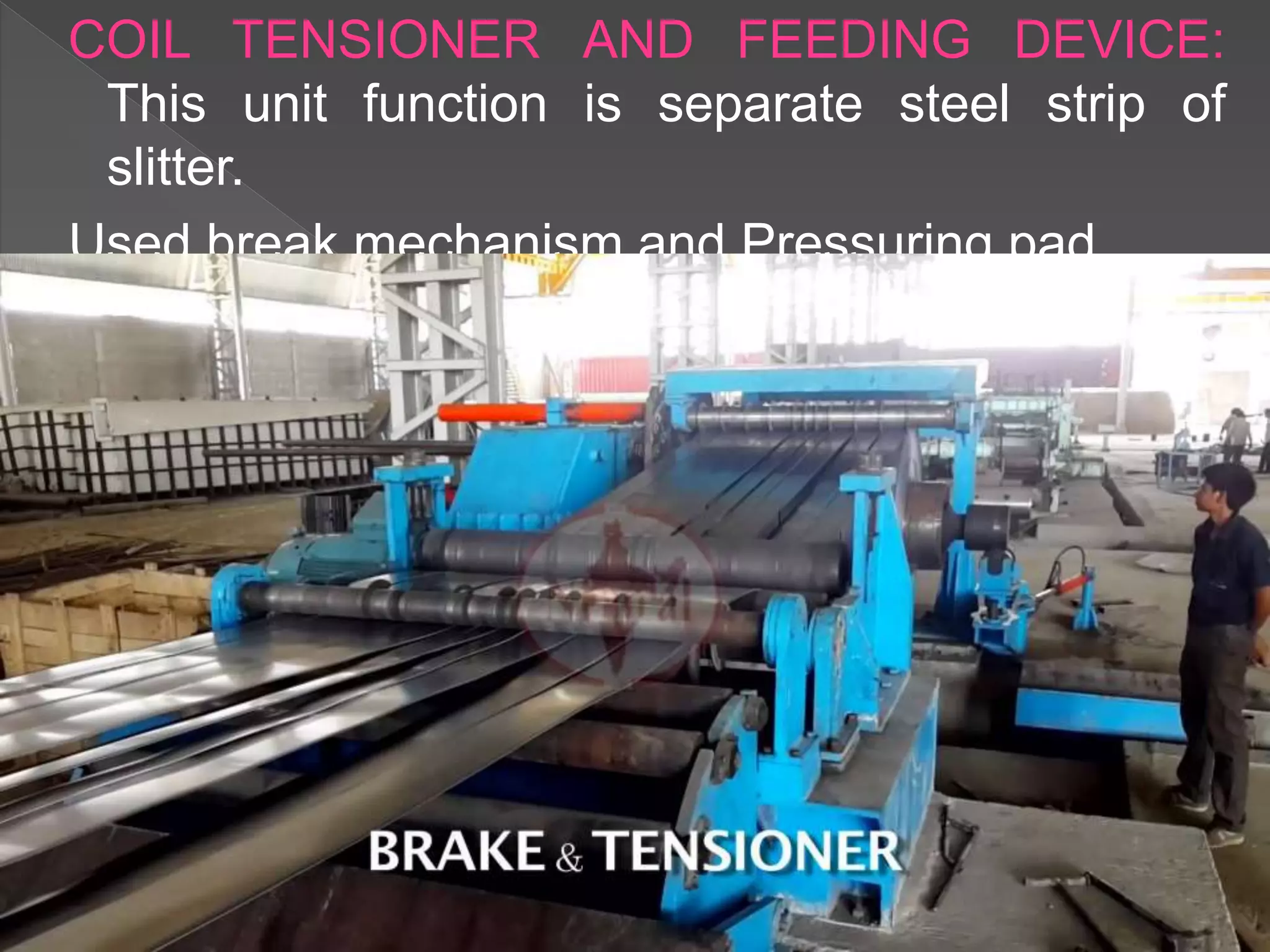

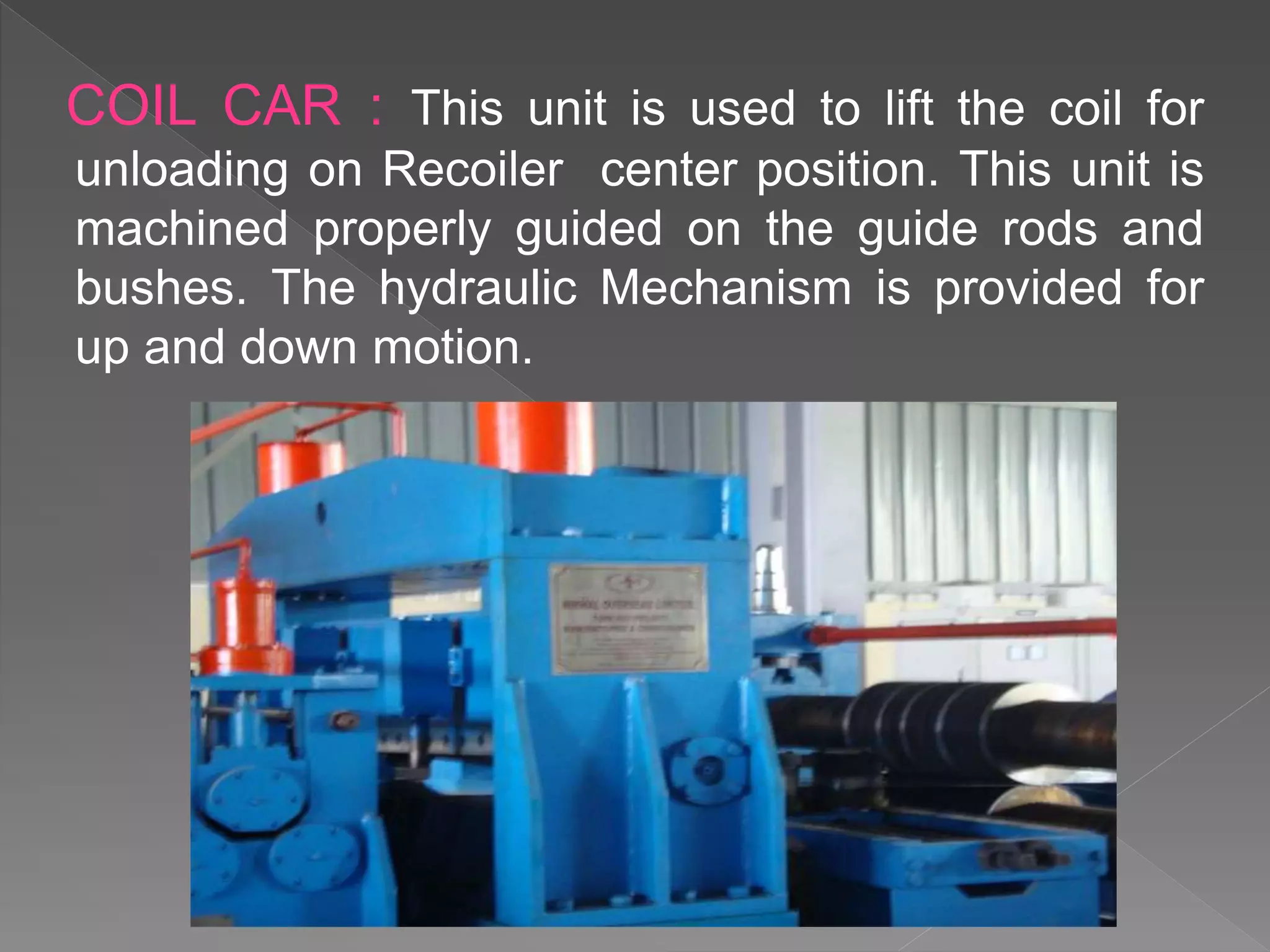

The document details the specifications and components of an automatic slitting machine capable of cutting sheet and slitting coils with wall thickness ranging from 0.5 mm to 10 mm. It provides a comprehensive list of equipment including the coil rest saddle, snubber, uncoiling unit, and cutting mechanisms, along with their functionalities and hydraulic mechanisms. Contact information for the manufacturer, Nirmal Overseas Ltd., is also included.