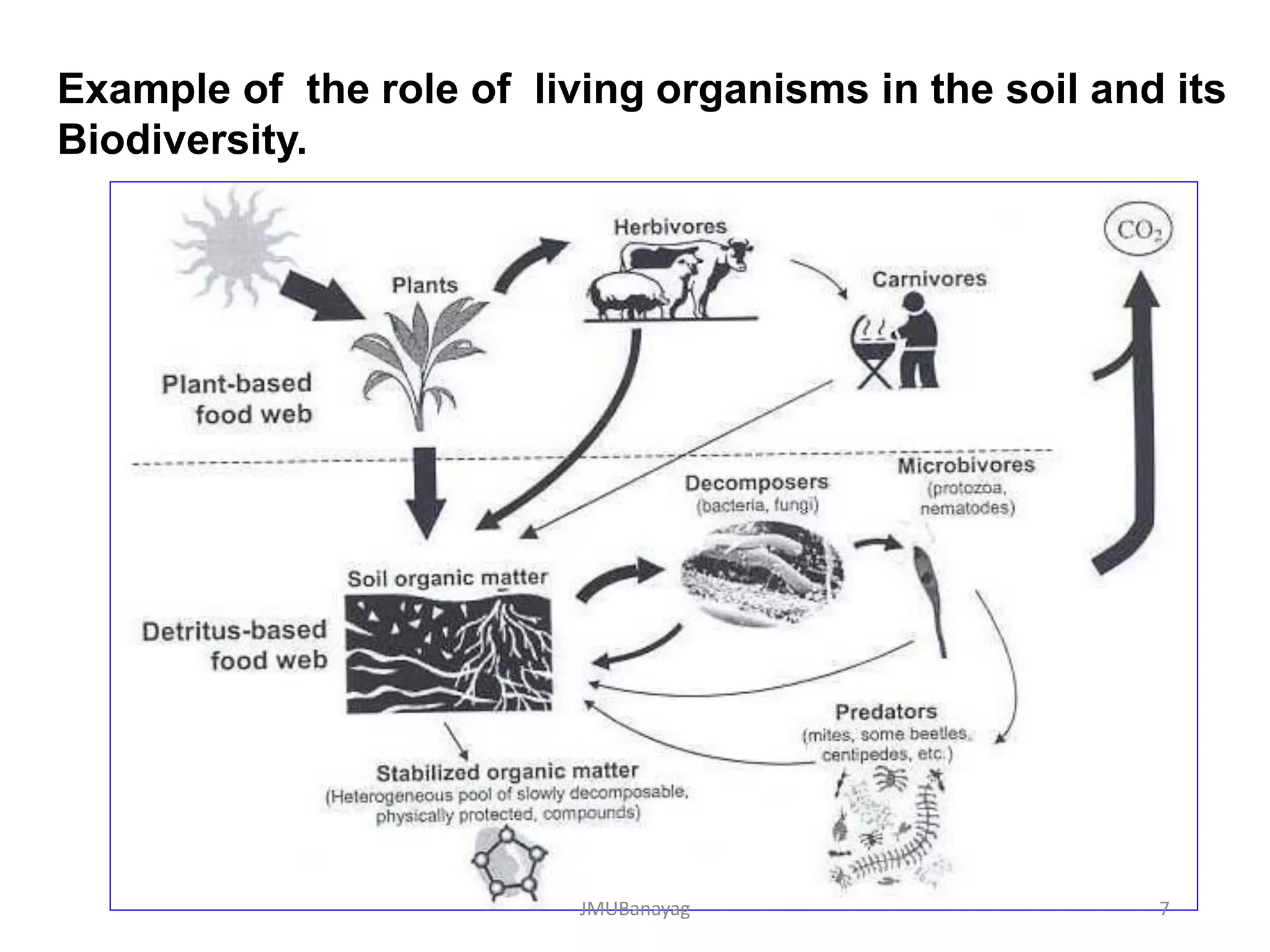

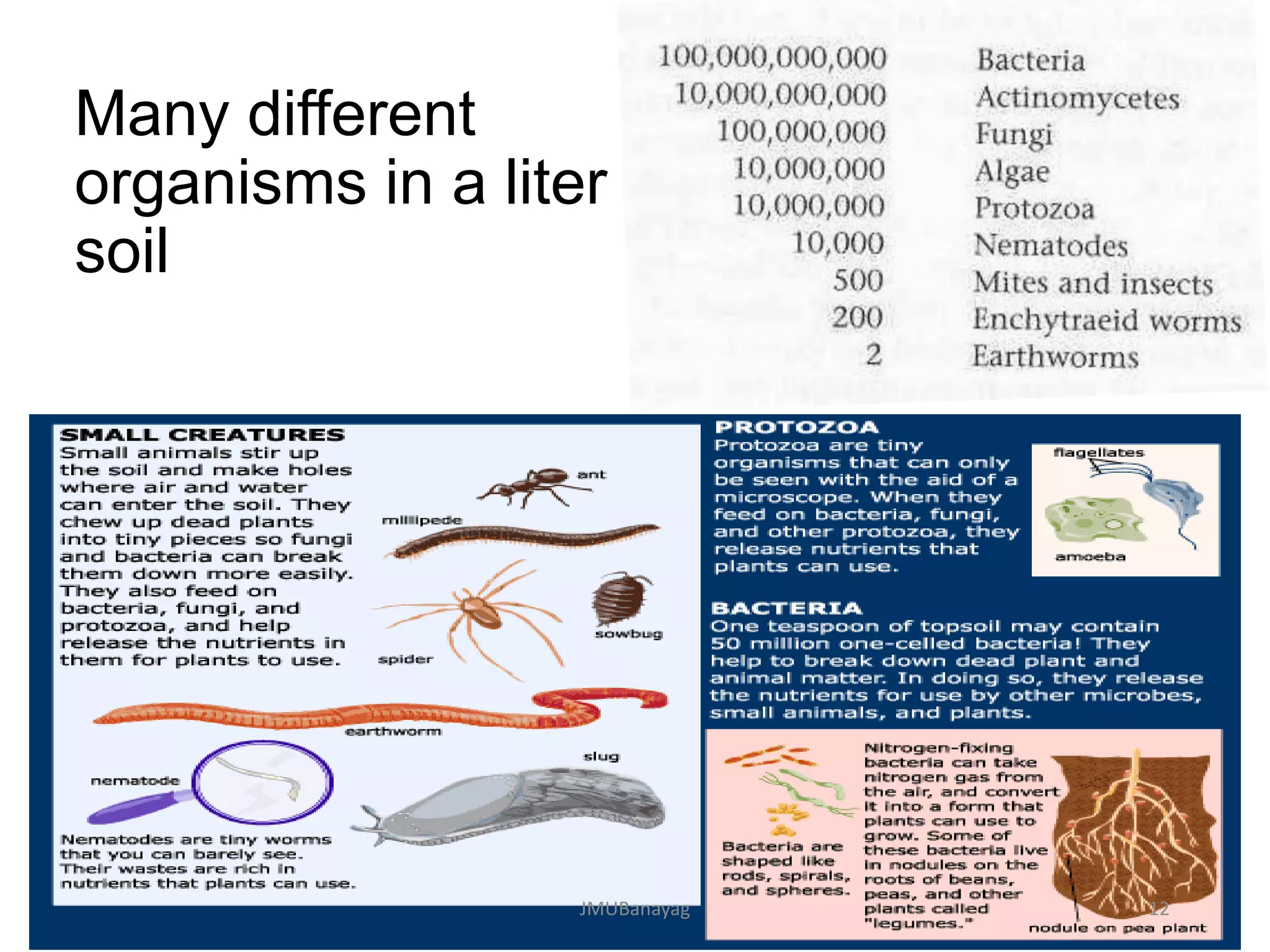

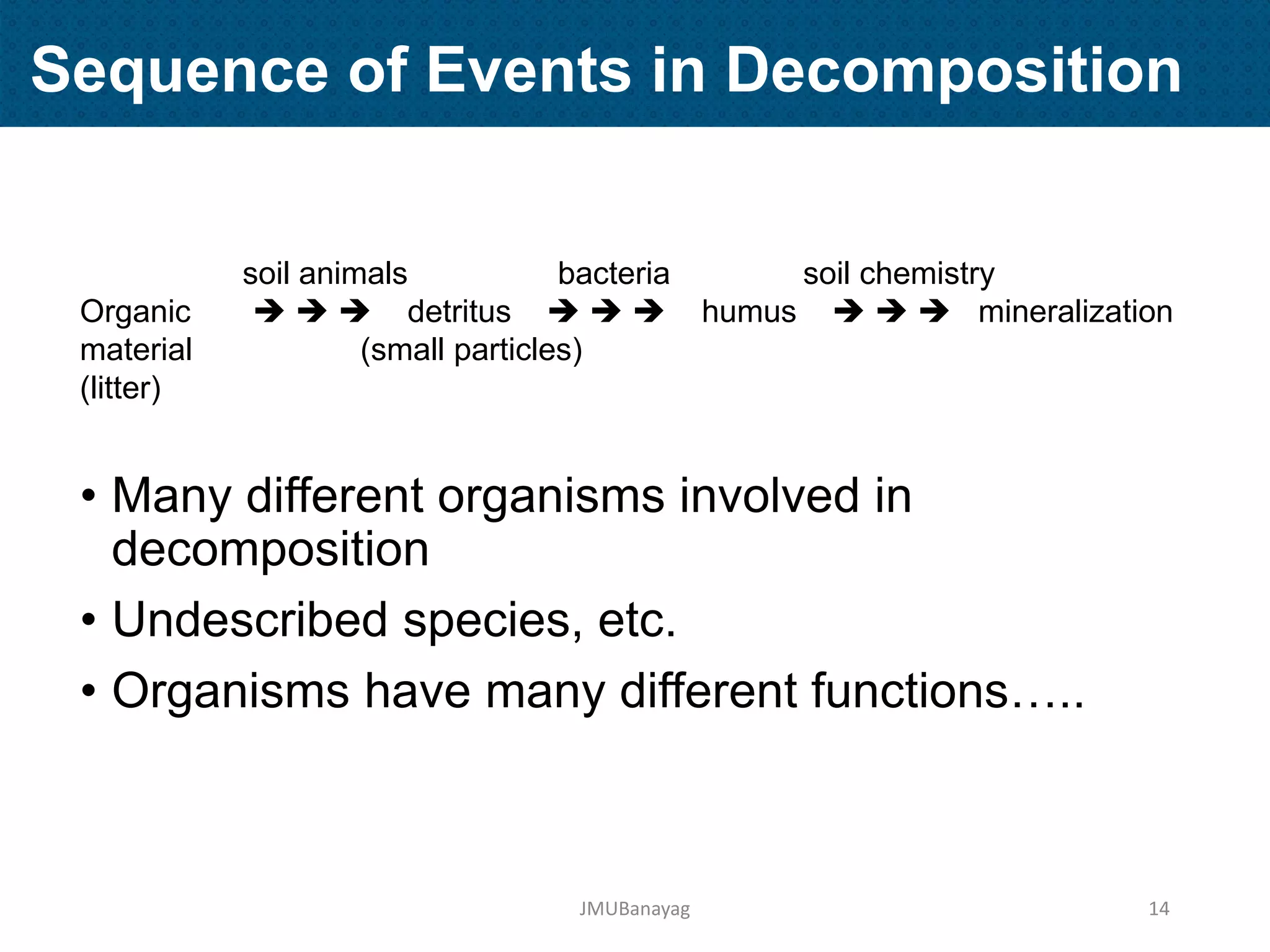

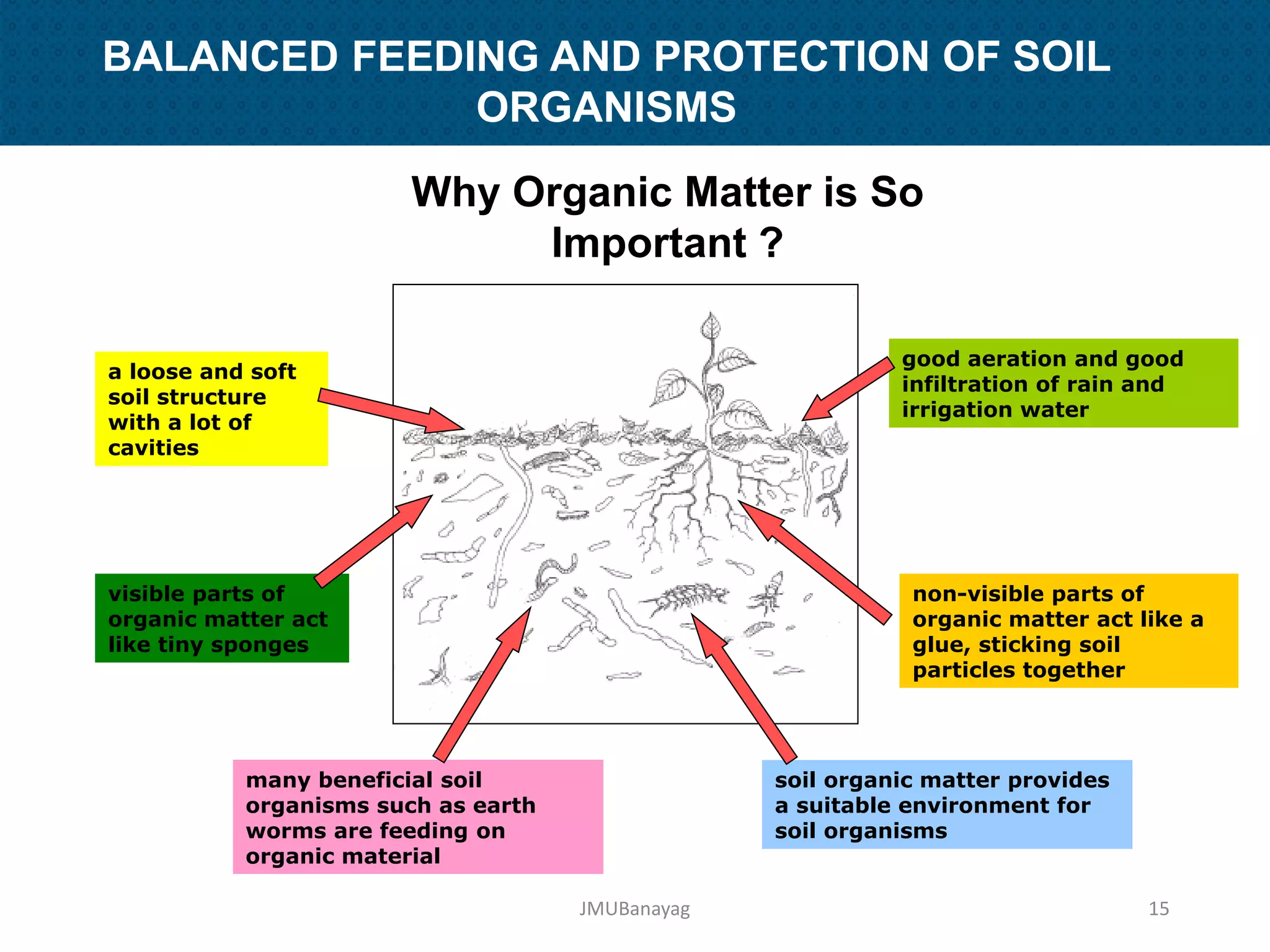

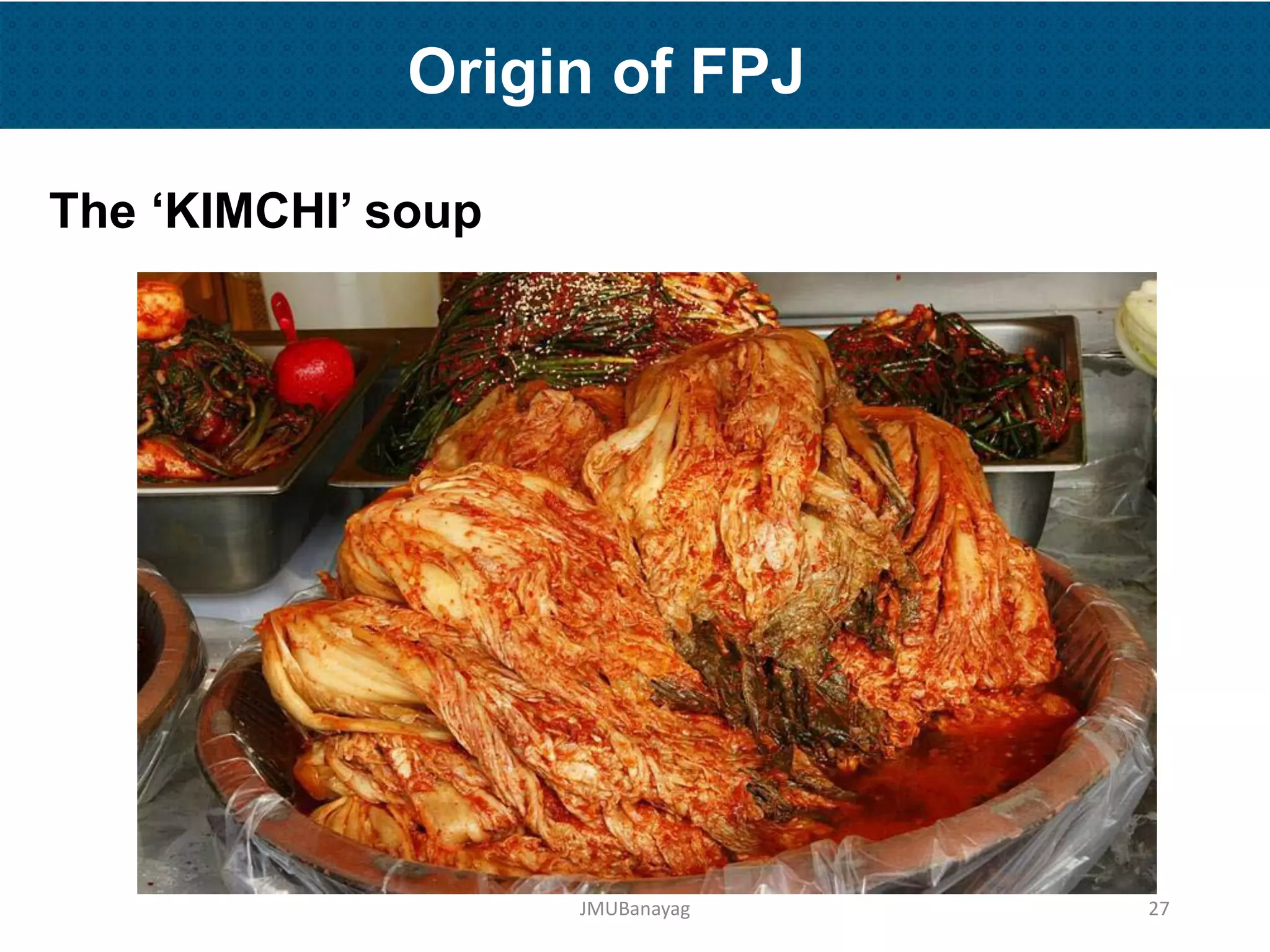

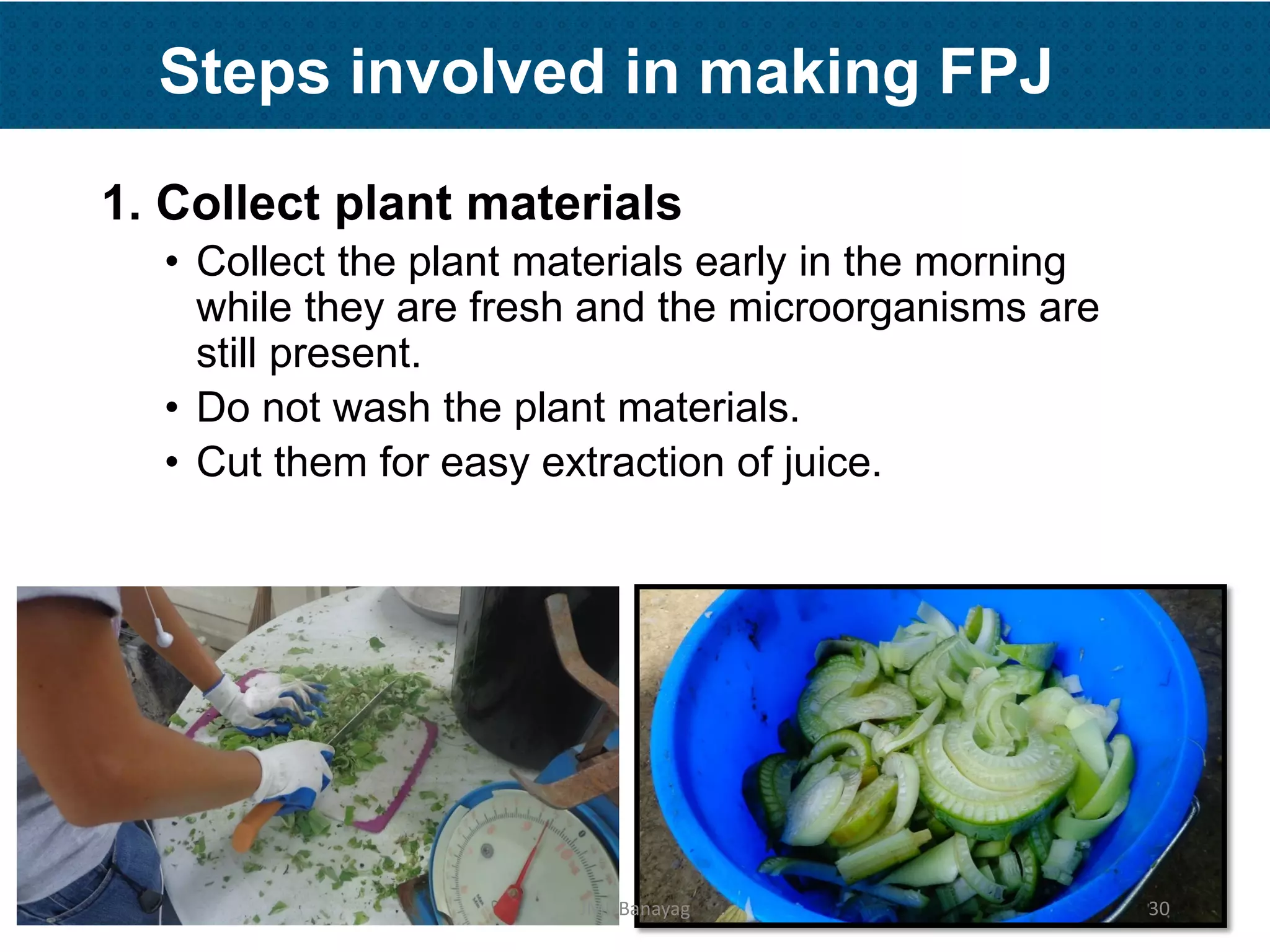

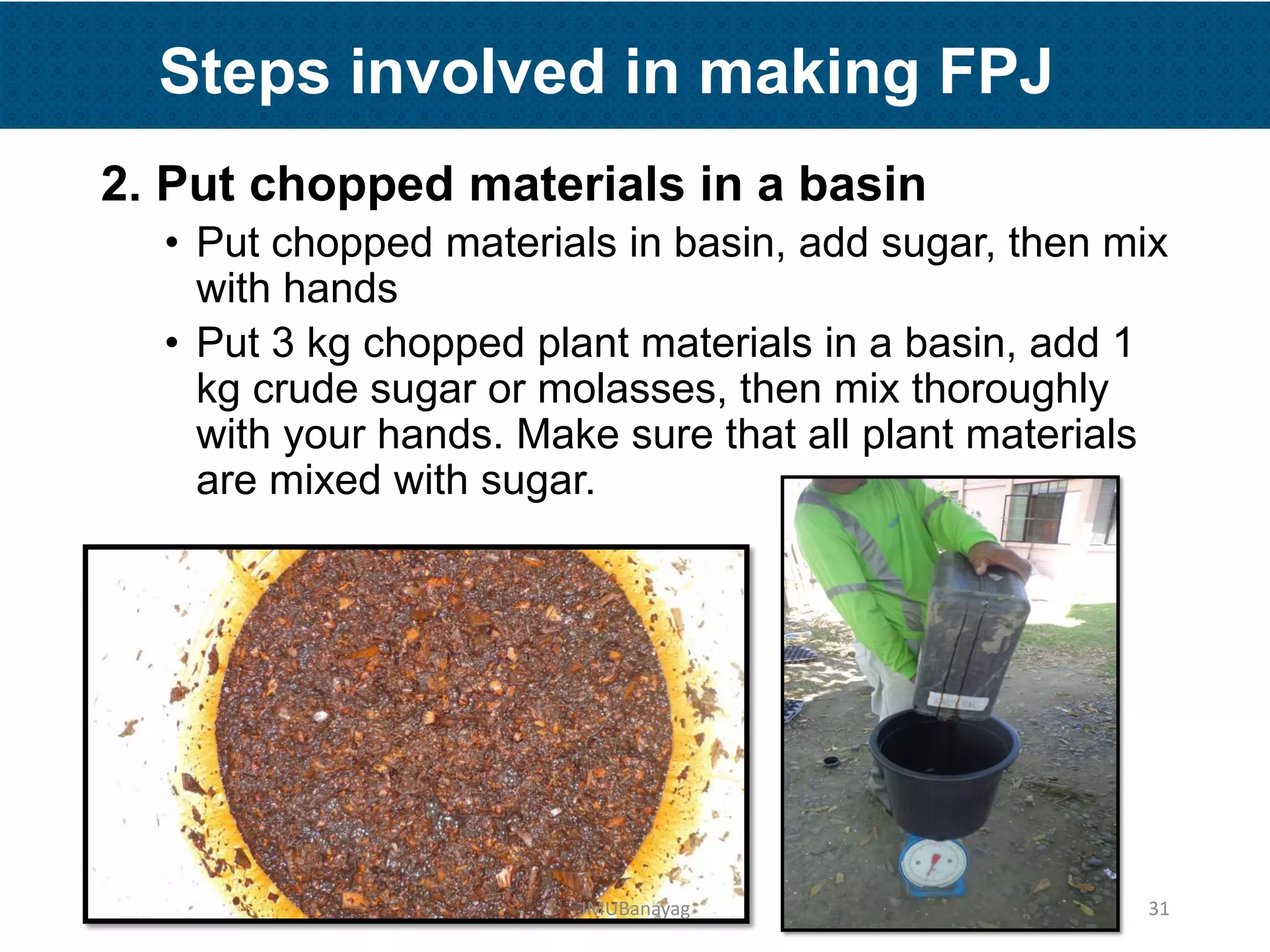

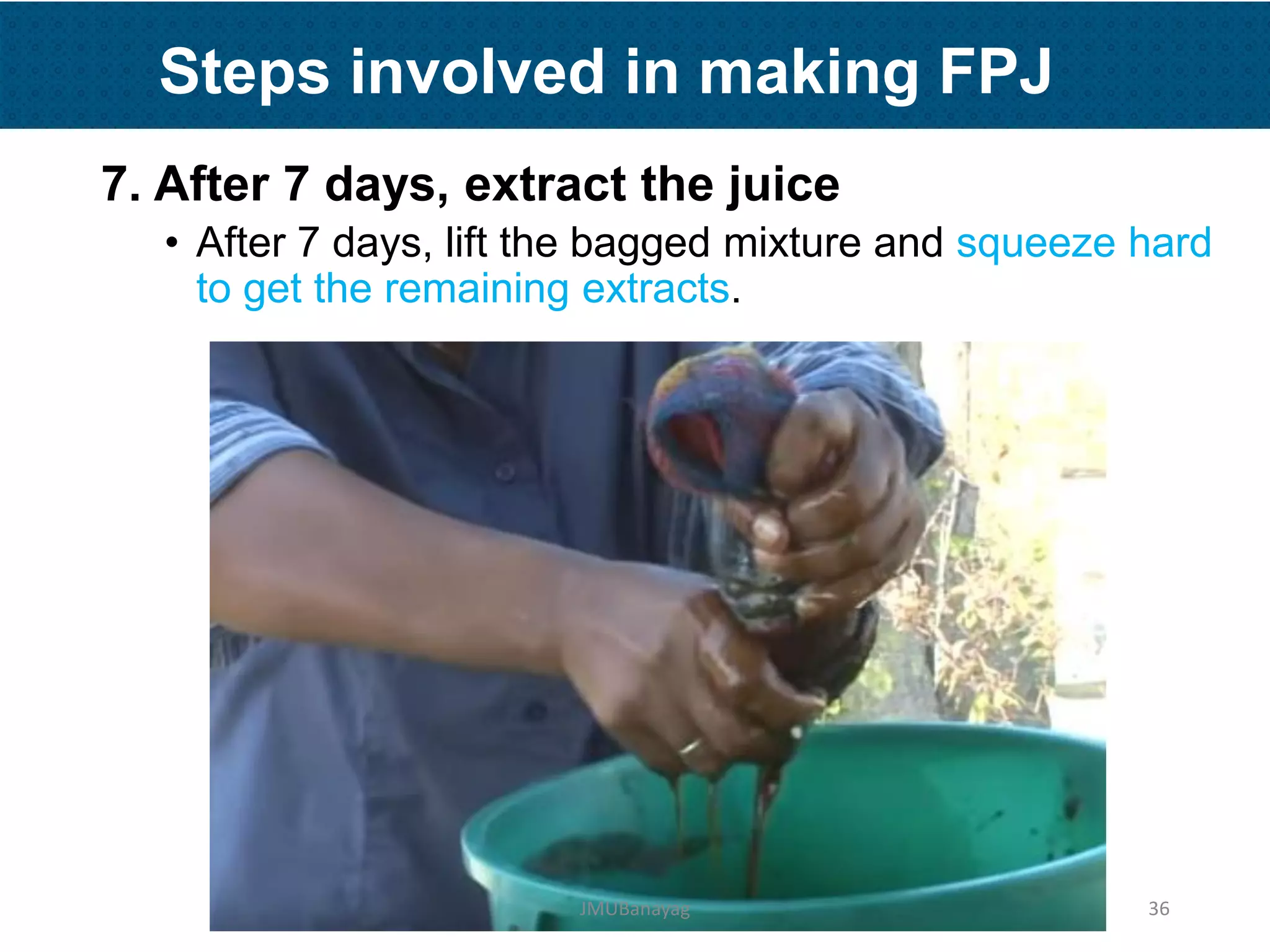

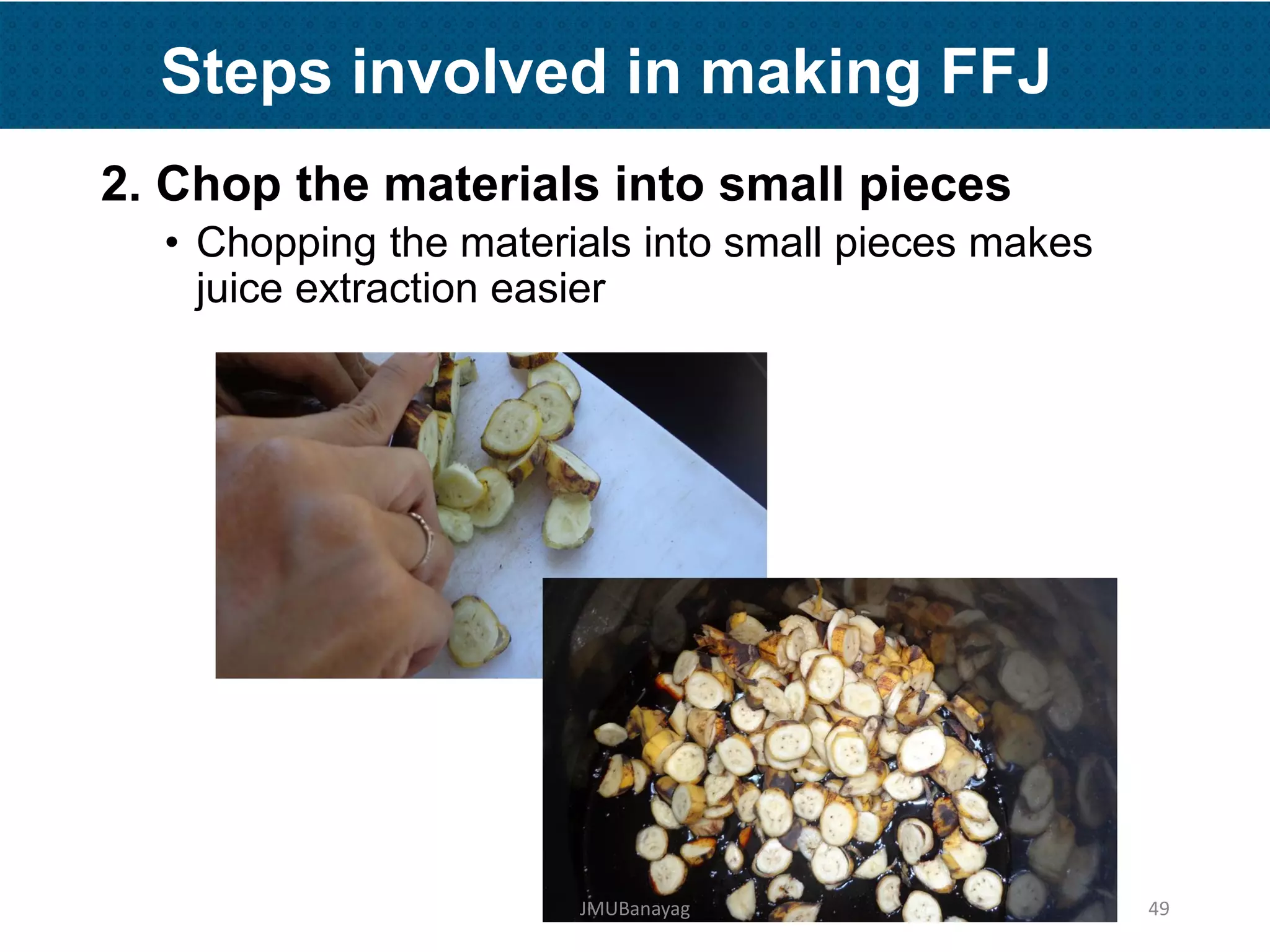

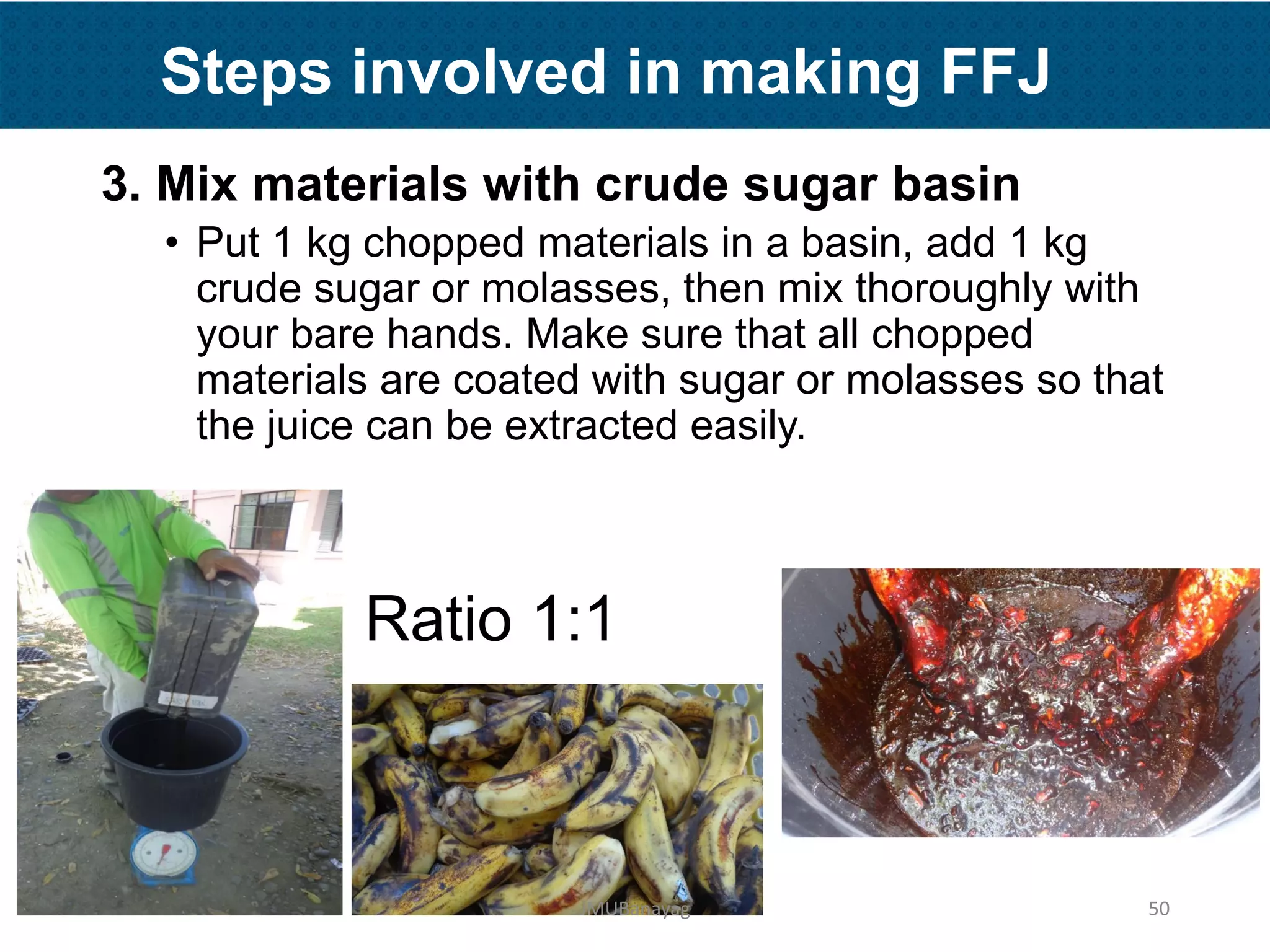

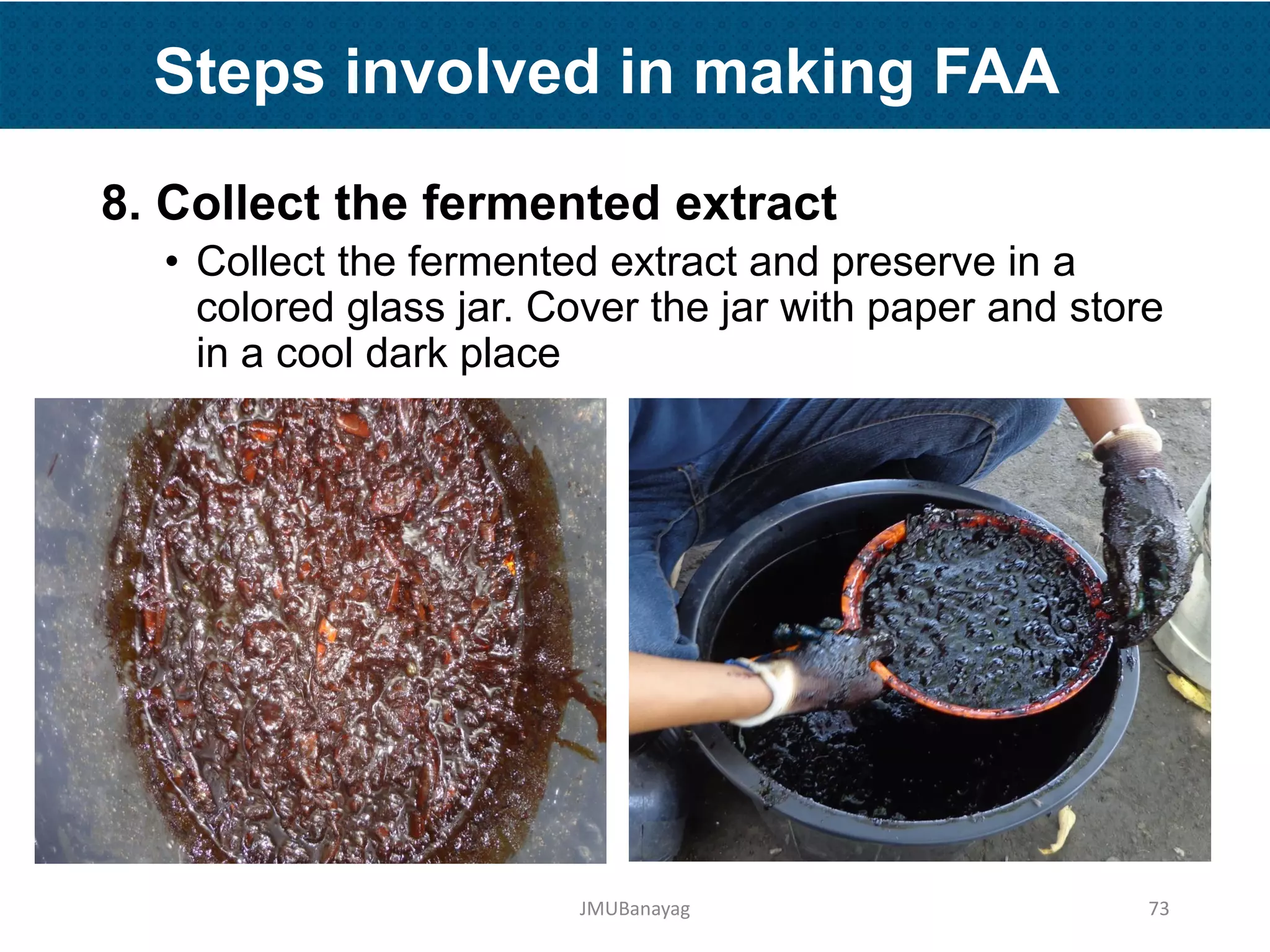

The document outlines a seminar on organic concoctions and extracts focused on natural farming inputs, including procedures for preparing liquid organic farm inputs. It covers principles of organic agriculture, benefits of soil biodiversity, and specific concoctions like Fermented Plant Juice (FPJ) and Fermented Fruit Juice (FFJ) detailing their preparation, application, advantages, and limitations. The material emphasizes sustainable farming practices, encouraging users to apply these organic solutions to enhance plant growth and soil health.