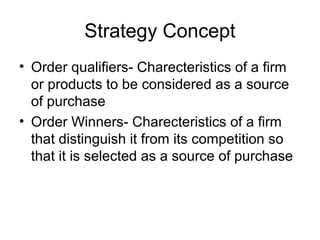

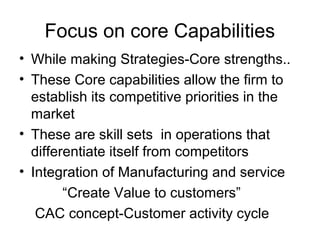

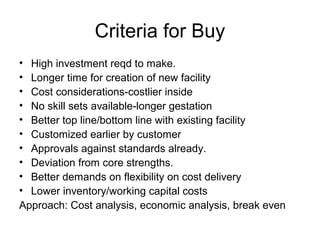

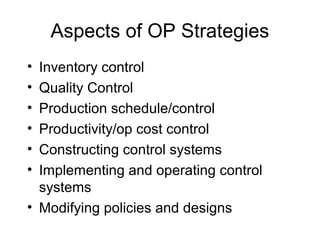

The document discusses various aspects of operations strategy. It covers defining operations strategy and linking it to corporate strategy. It also discusses developing strategies at different time horizons - strategic/long term, tactical/medium term, and operational/short term planning. Key aspects include product/service profiling, implementation of strategies, and adapting strategies to dynamic market conditions. The overall purpose is to effectively manage operations and add value for customers.