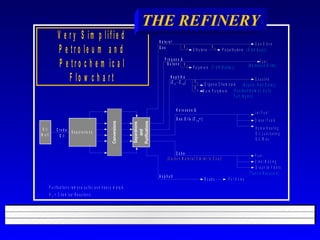

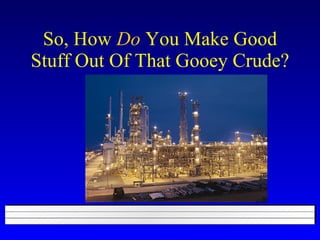

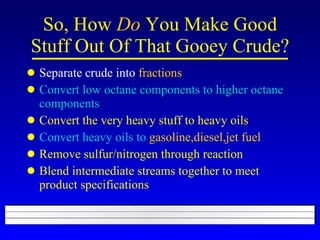

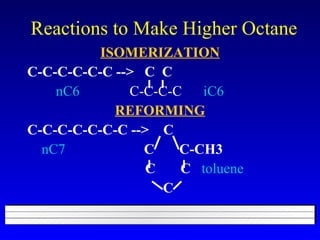

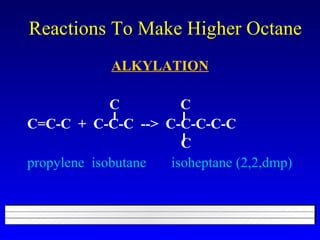

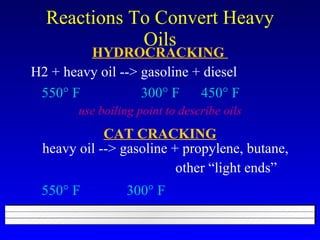

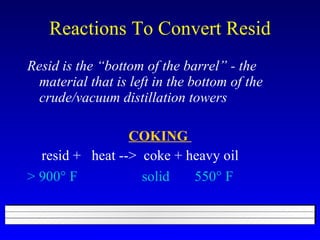

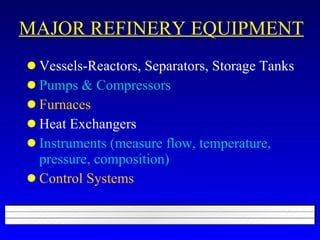

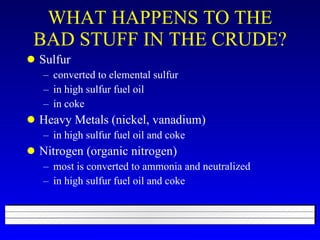

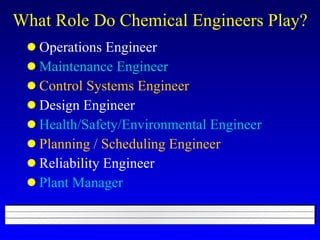

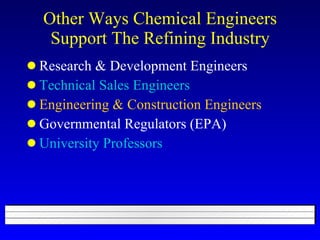

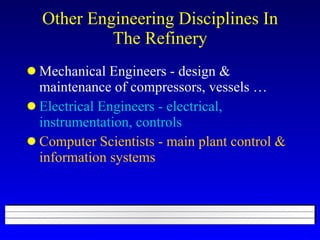

An oil refinery transforms crude oil into high value products like gasoline, diesel, and jet fuel through a series of chemical reactions and separations. Chemical engineers play a key role in designing, operating, and maintaining refineries to efficiently and safely convert crude oil fractions into products that meet specifications, while minimizing pollution and environmental impact. Refineries employ large distillation columns, reactors, storage tanks, heat exchangers and other equipment to separate crude oil into fractions and upgrade fractions into higher octane fuels and other products through reactions like isomerization, reforming, and hydrocracking.