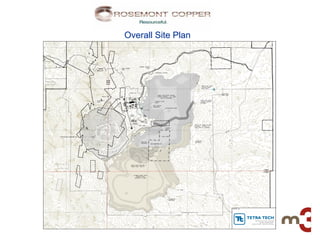

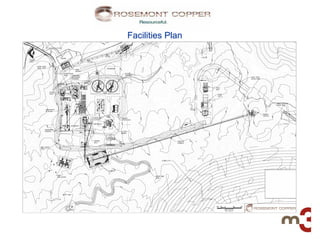

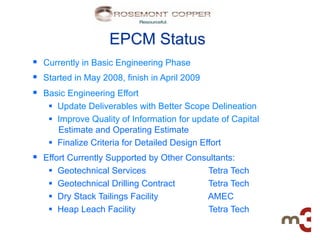

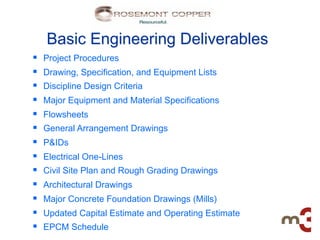

The document outlines M3 Engineering & Technology Corporation's facilities engineering scope for a site plan, detailing process facilities, ancillary facilities, civil infrastructure, power supply, and fresh water supply. It includes specifics on sulfide and oxide processing plants, civil modifications for access roads, and associated water management systems. The current status indicates the project is in the basic engineering phase, with plans for the detail engineering phase to begin in February 2009.