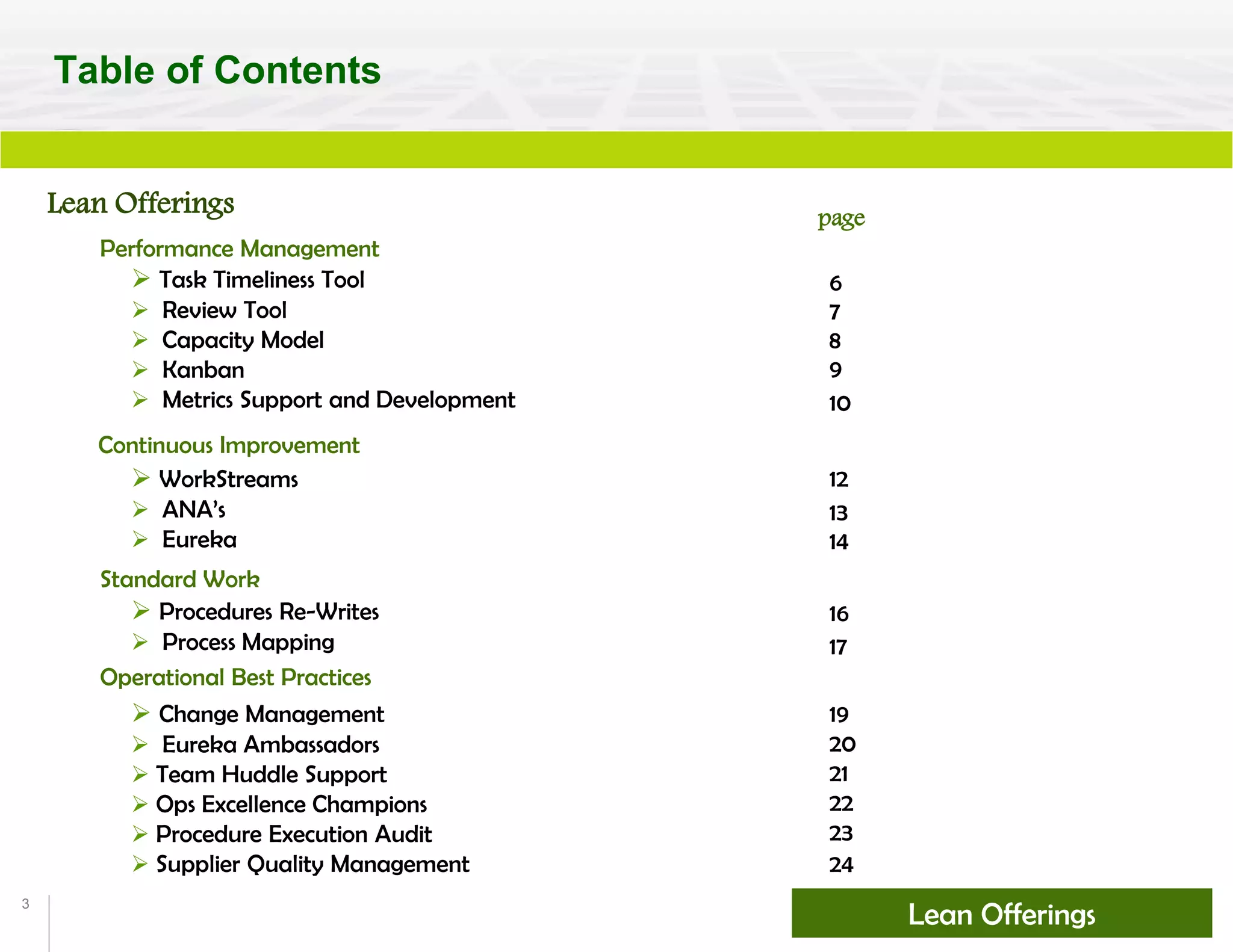

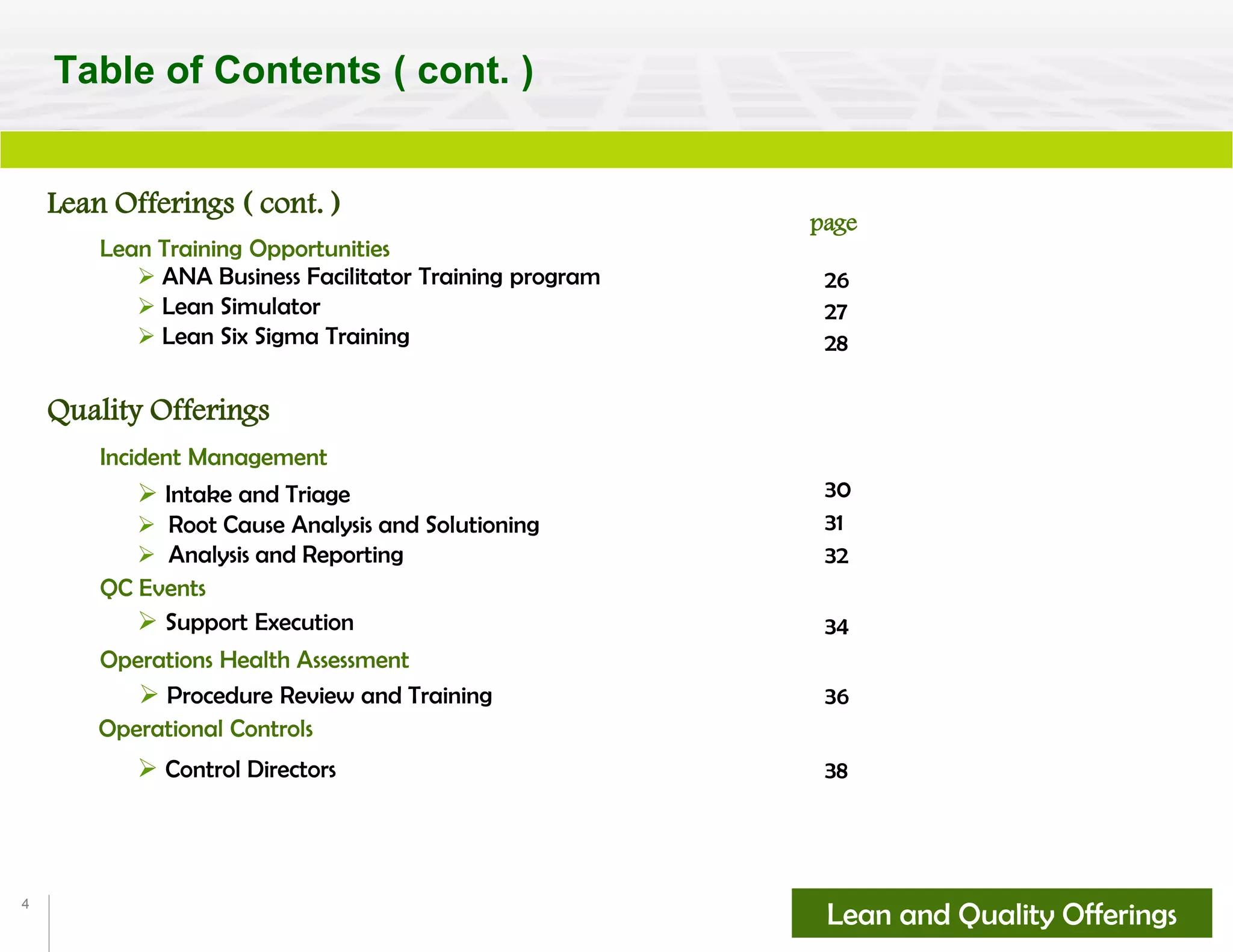

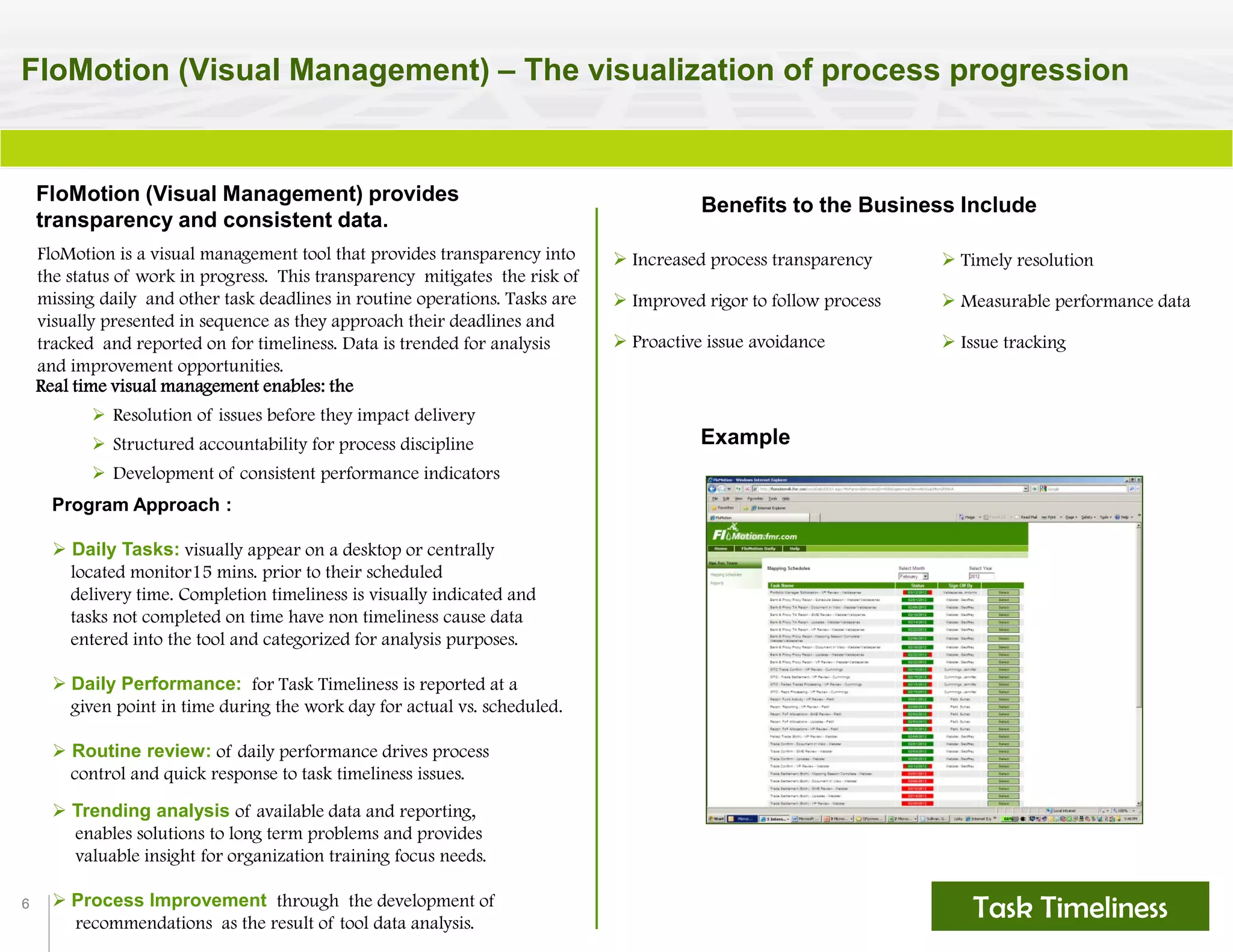

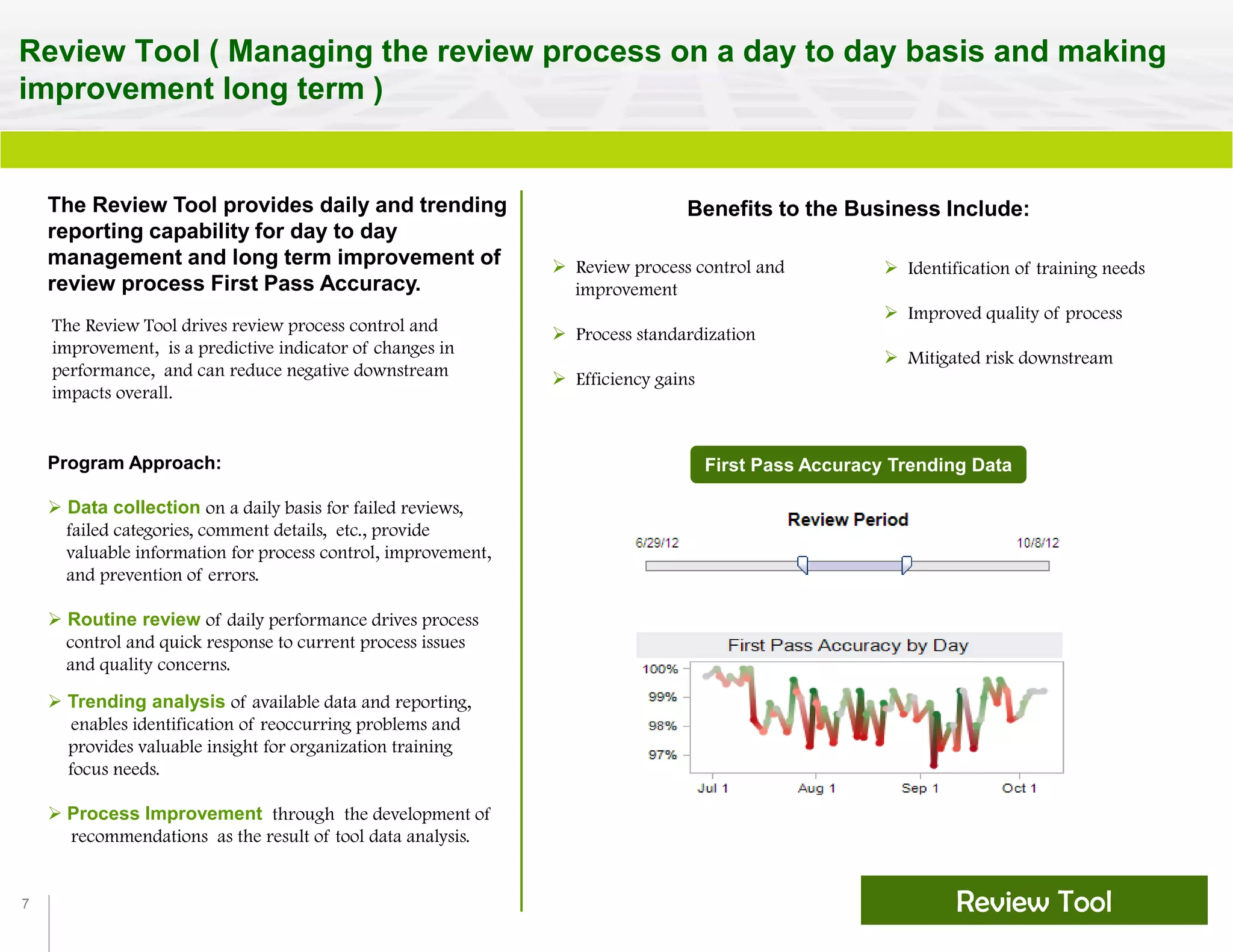

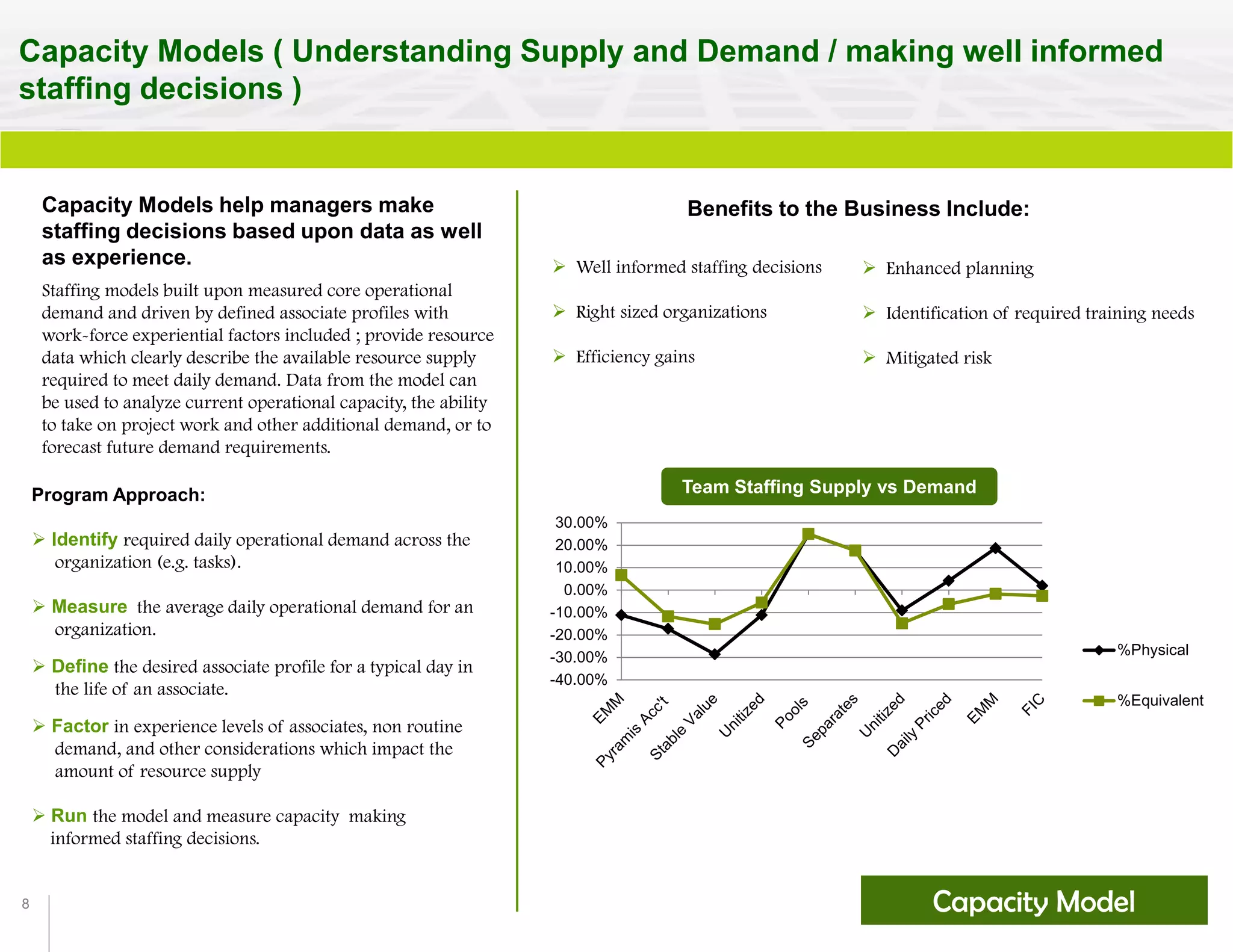

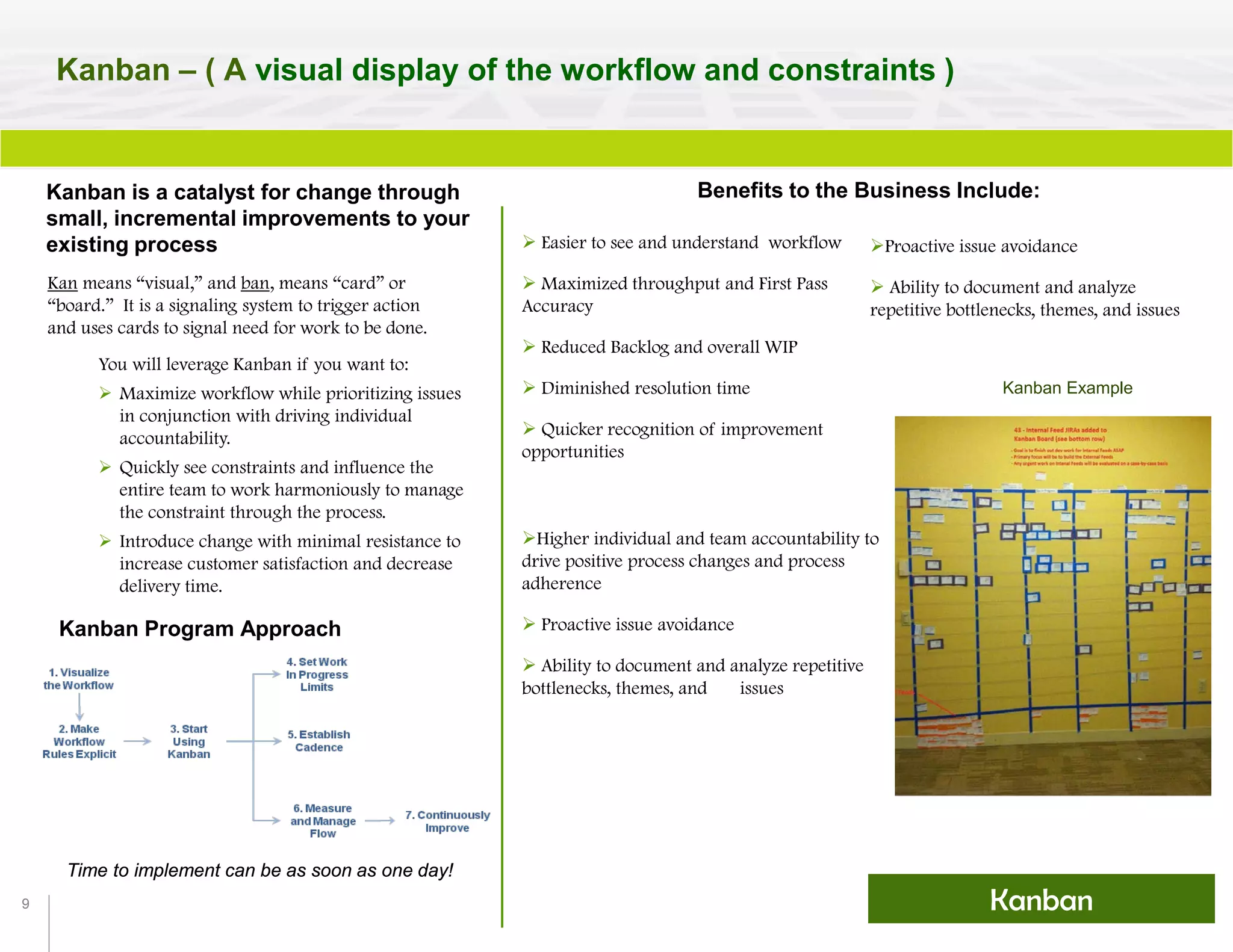

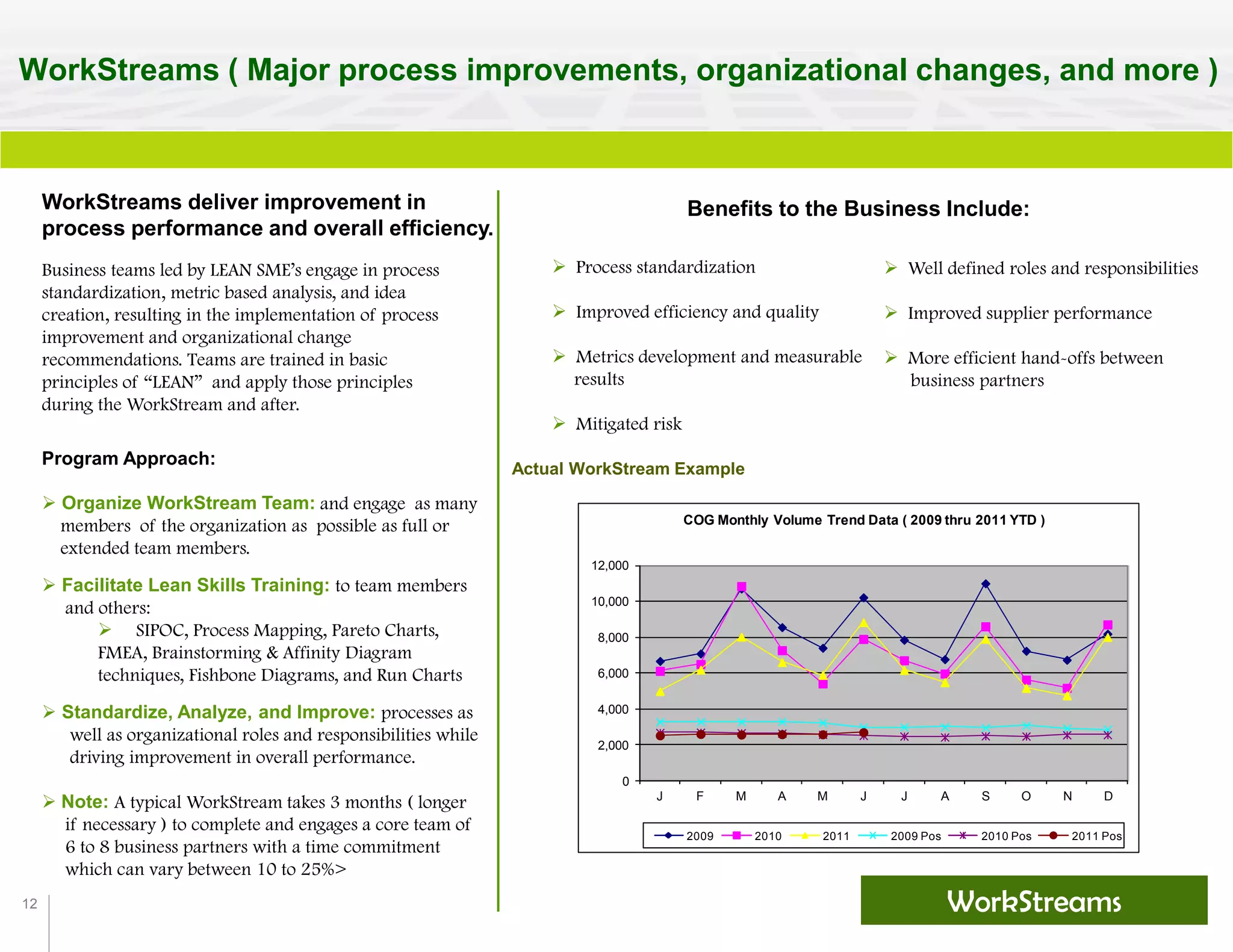

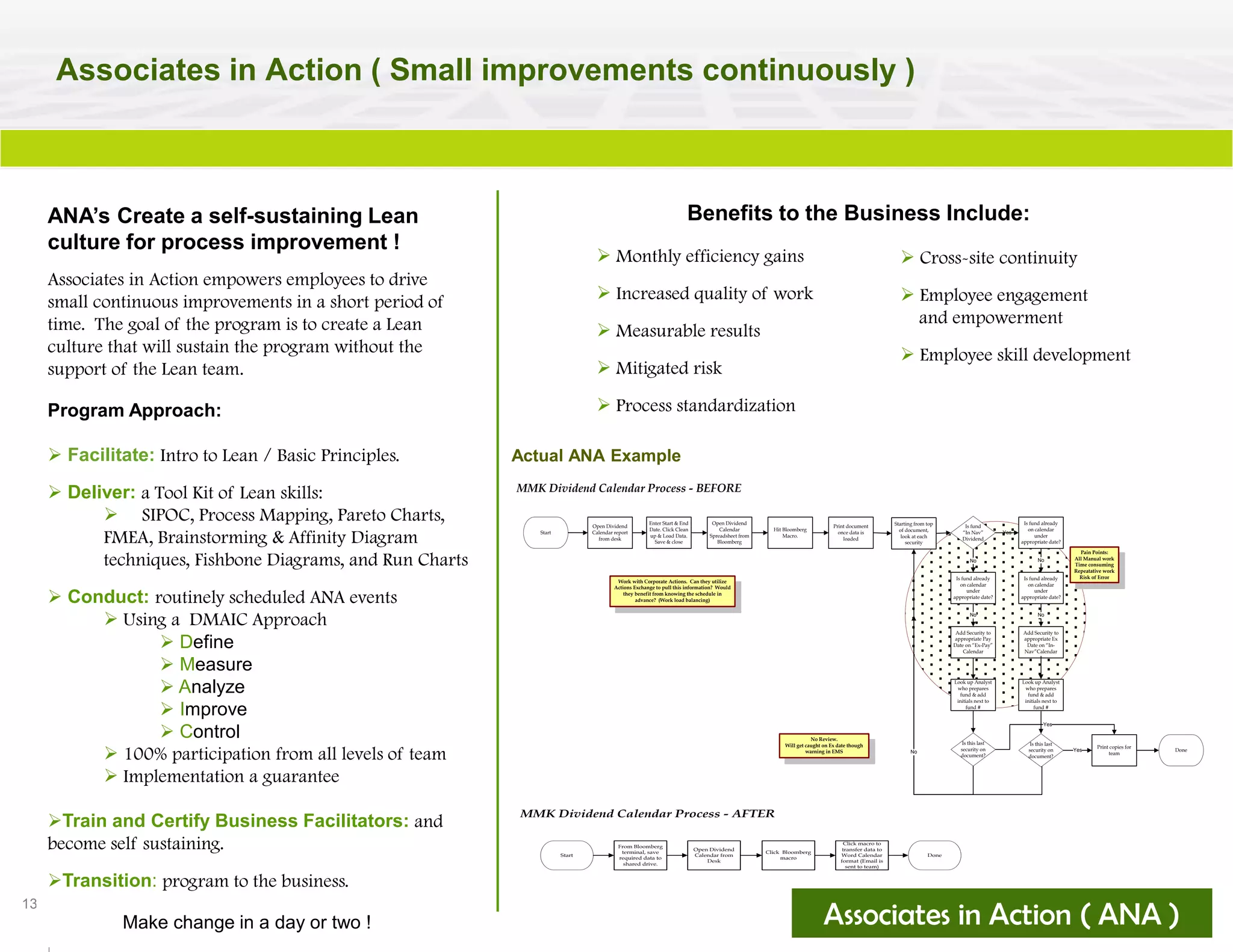

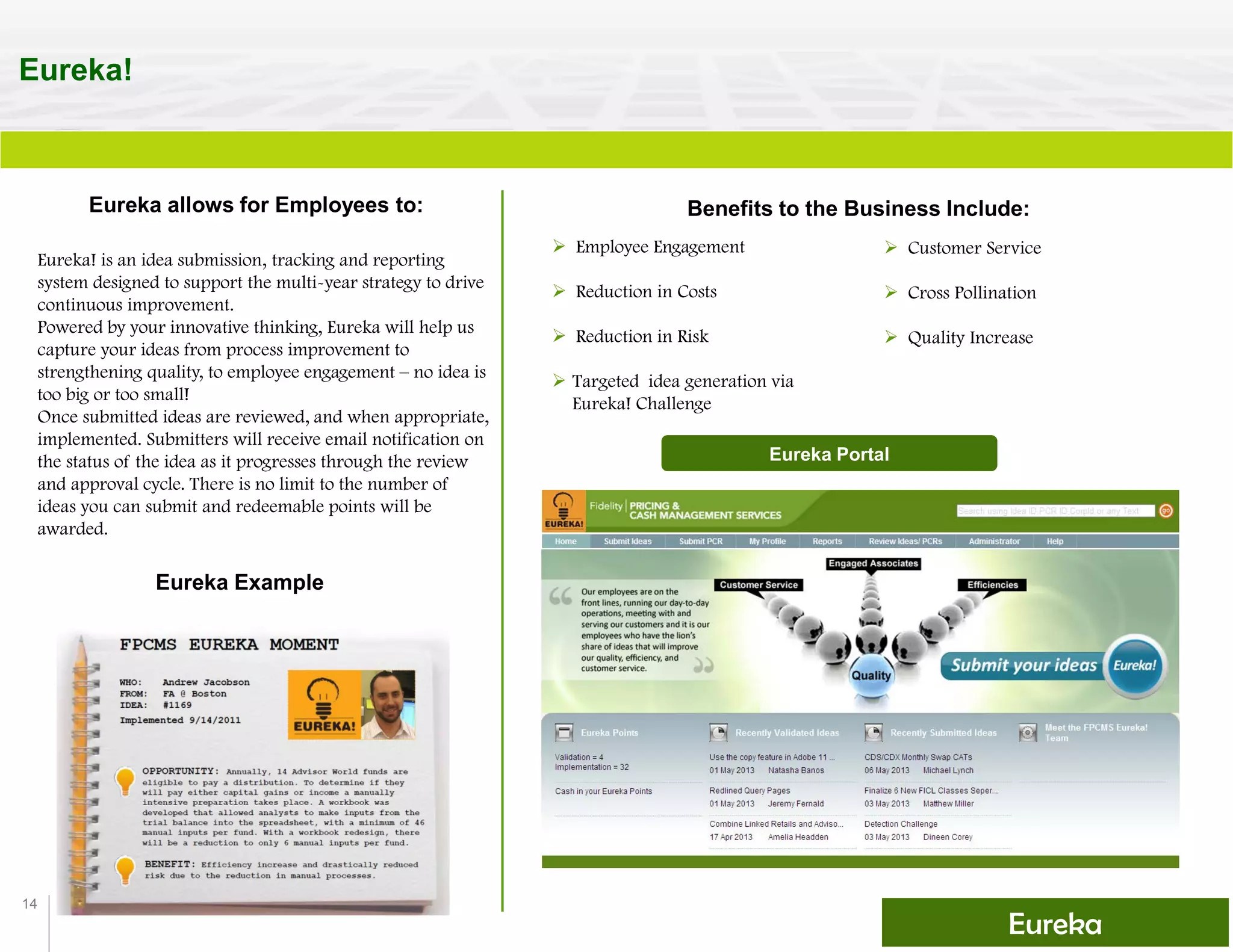

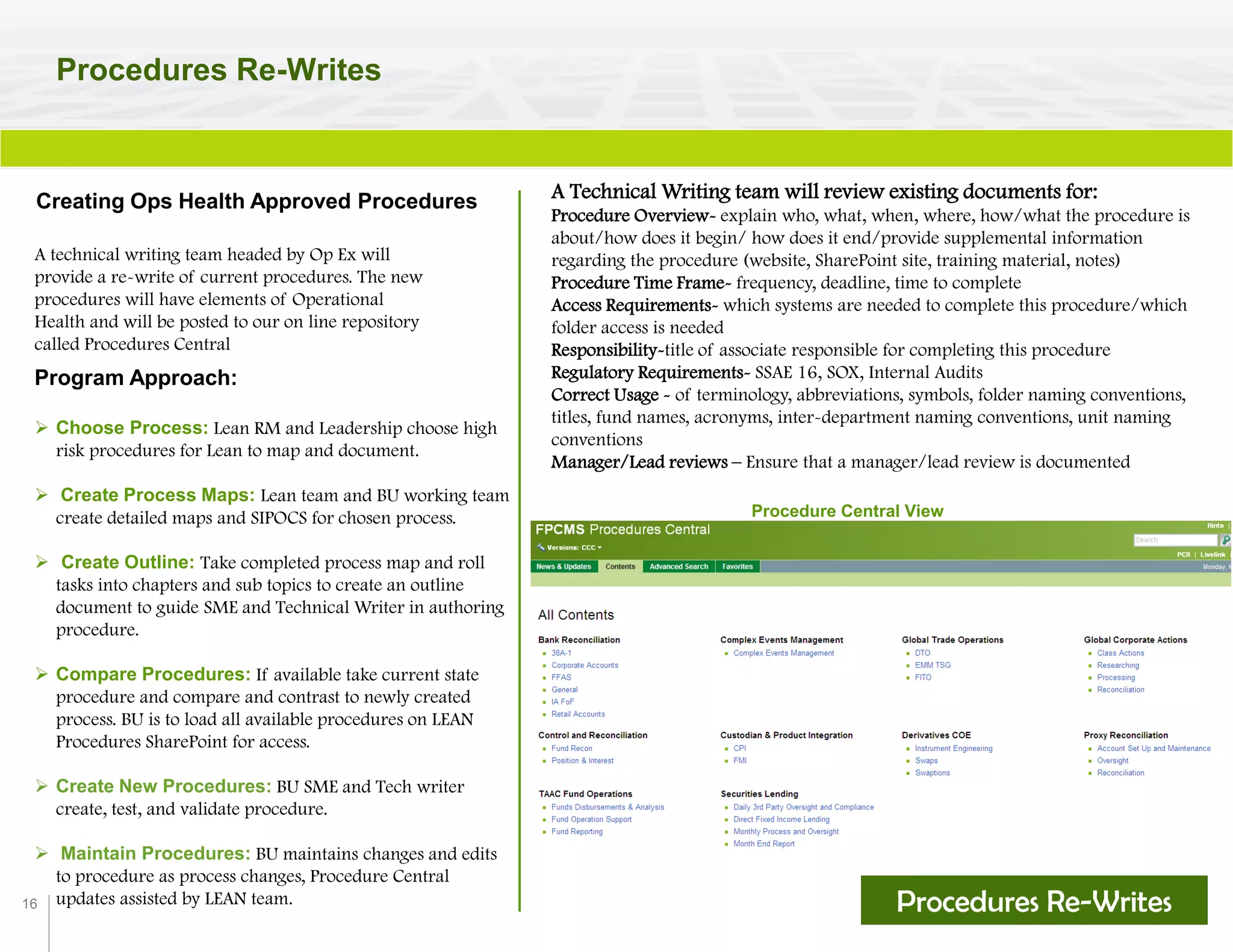

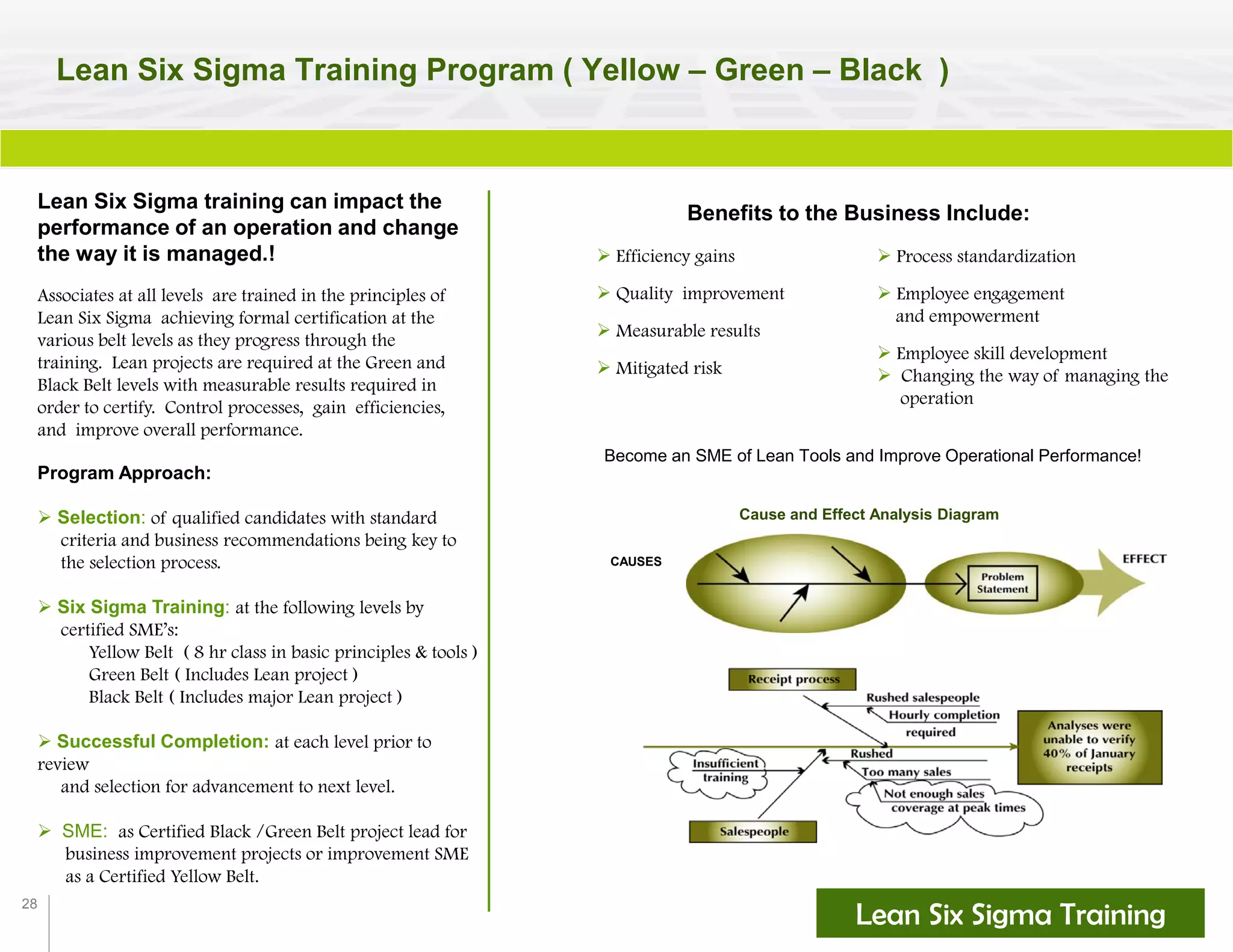

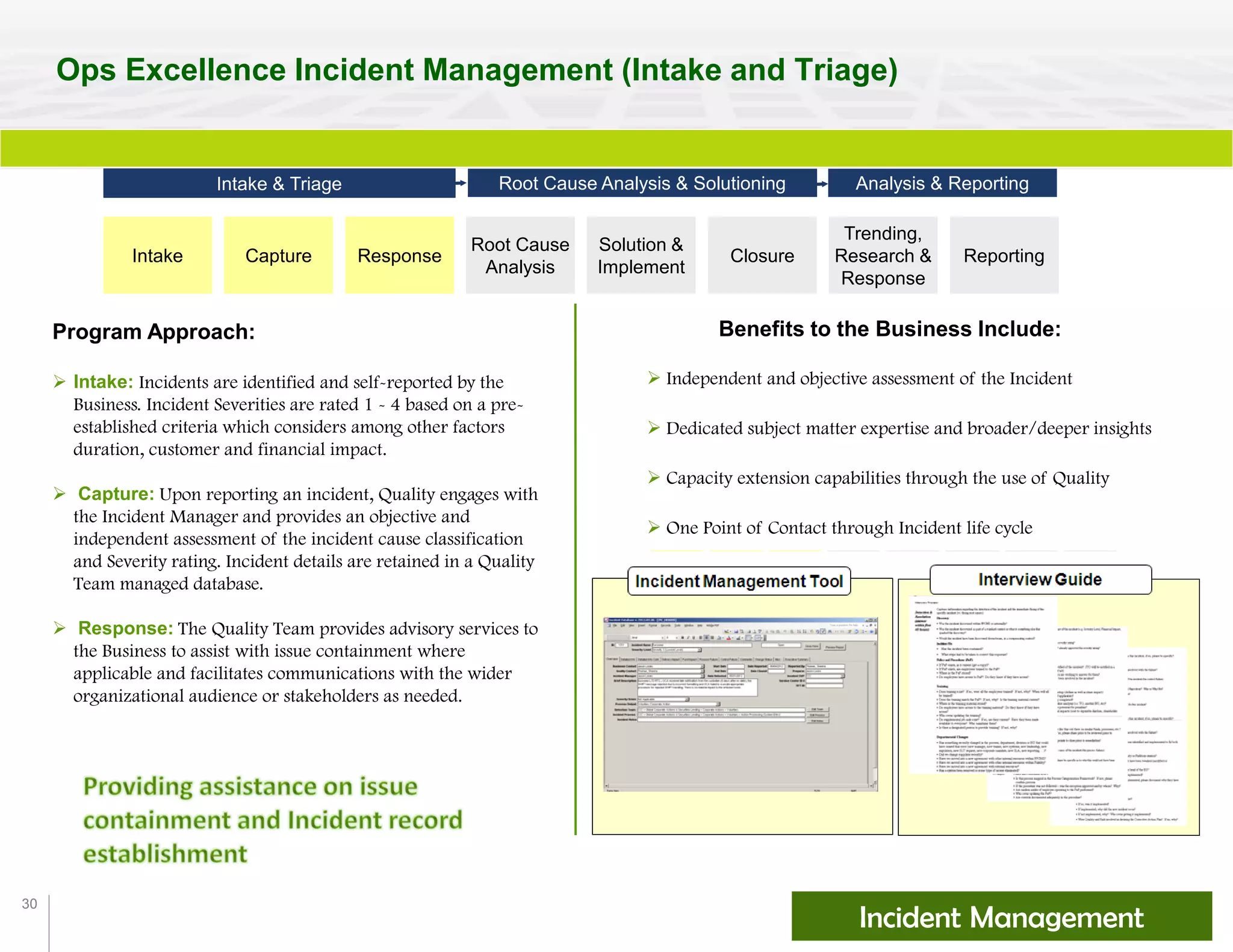

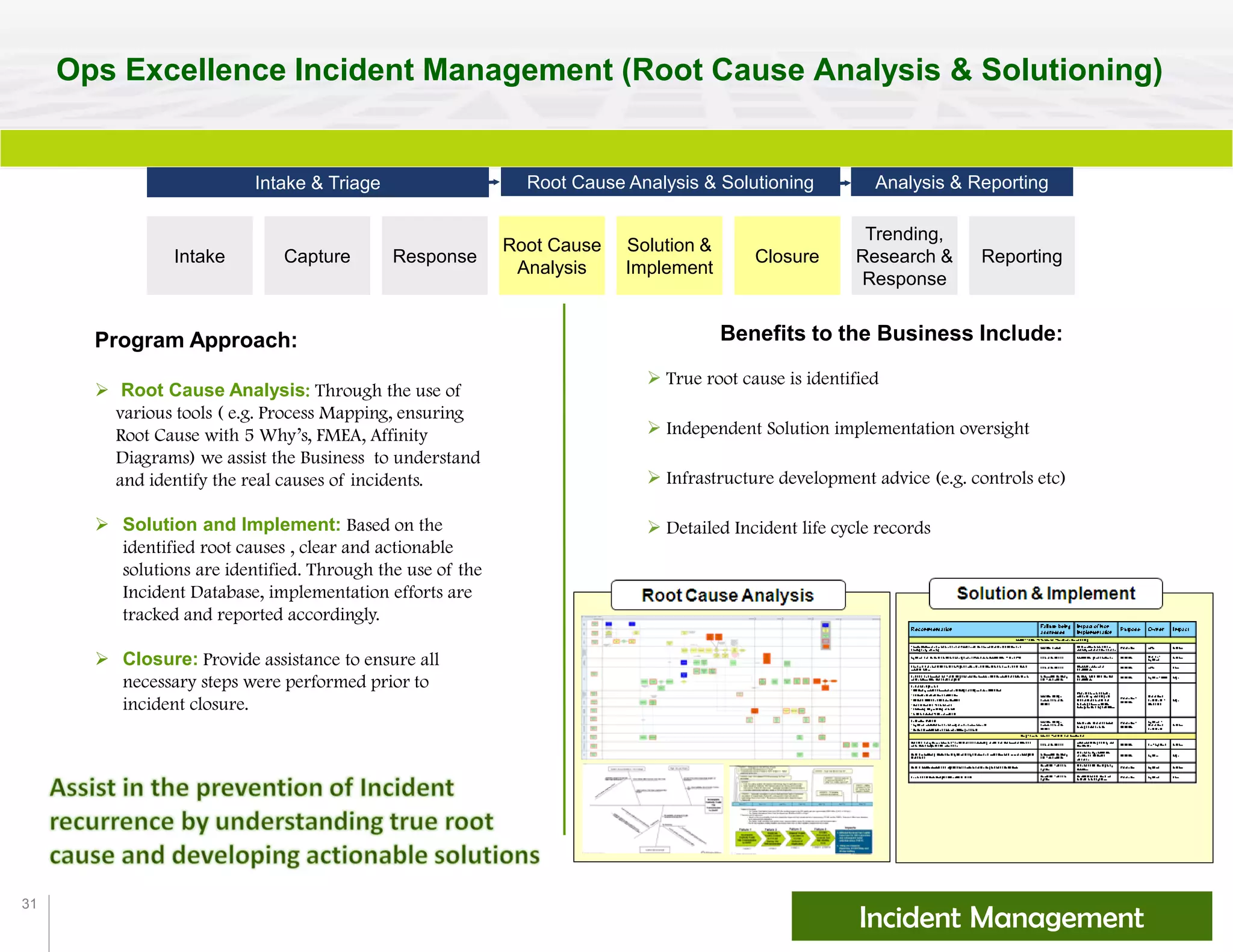

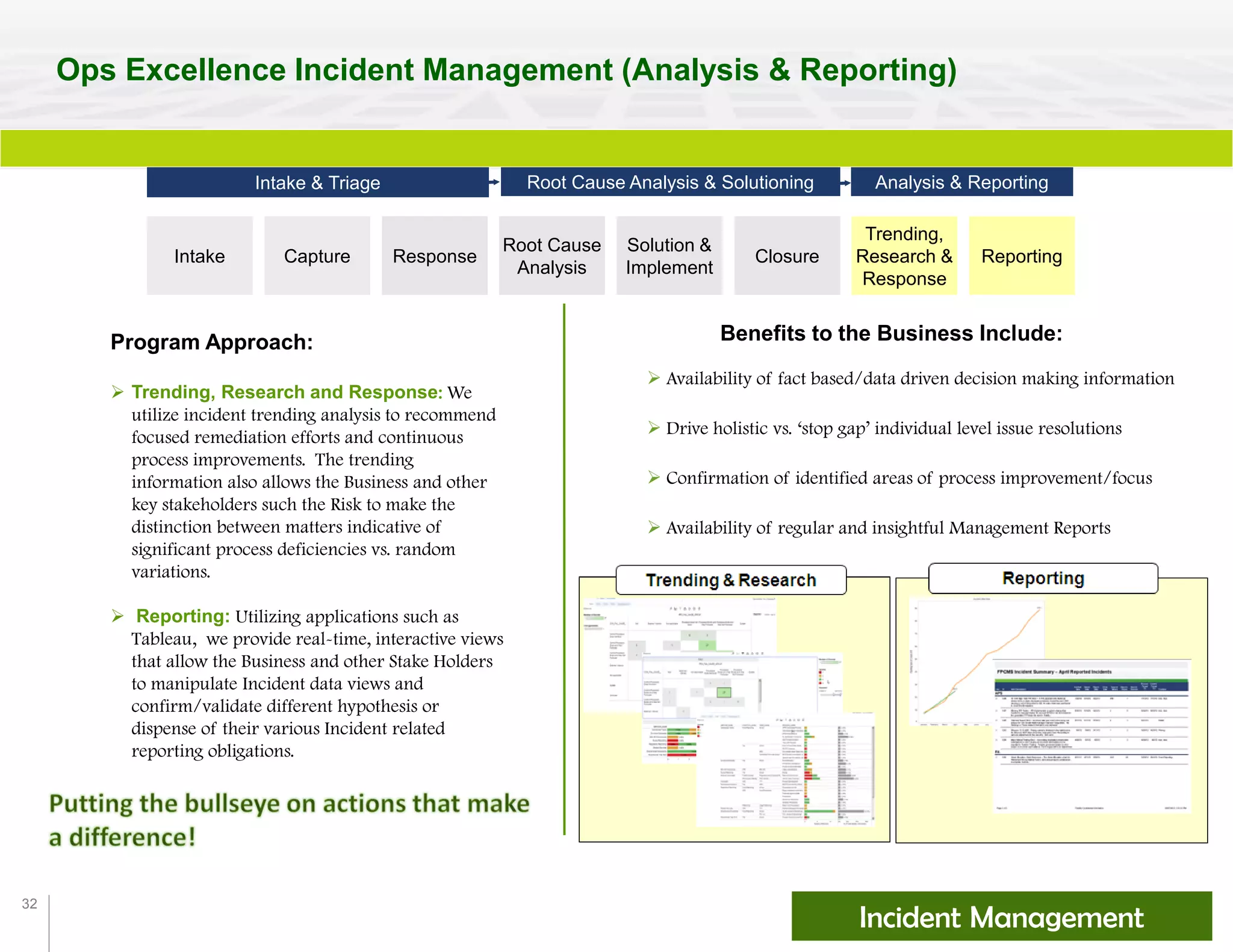

Operations Excellence offers a range of services to help organizations improve processes and operations. These include developing a culture of continuous improvement, implementing lean tools and methodologies, and assessing and improving processes, controls and metrics. Services are customized for each organization and aim to enhance quality, efficiency and associate engagement.