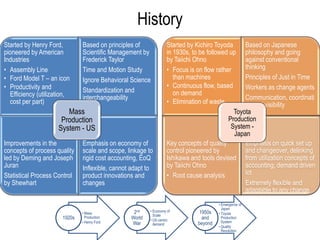

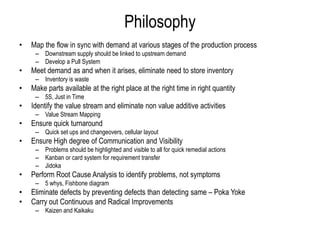

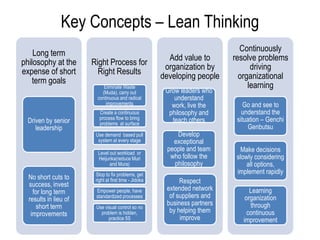

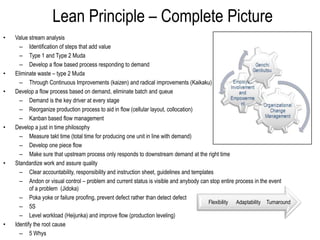

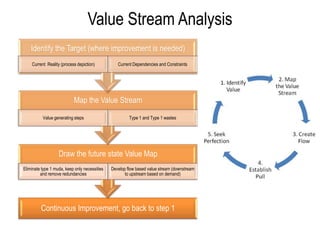

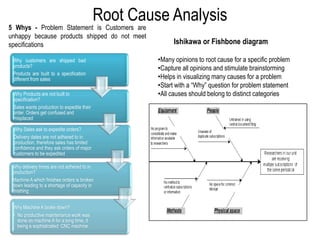

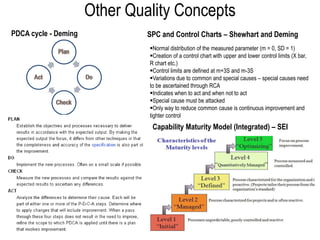

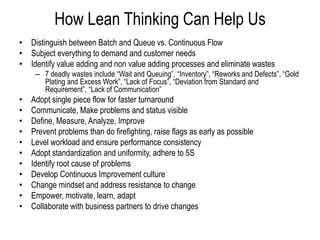

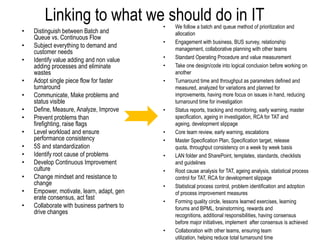

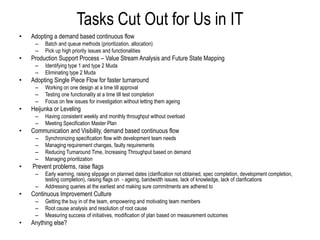

The document discusses key concepts and principles of lean thinking, CMMI, and process quality improvement. It covers topics like value stream mapping, identifying value-adding vs non-value adding activities, developing a pull-based system, continuous improvement, root cause analysis, and linking these concepts to how an IT team can improve processes. The tasks outlined for the IT team include adopting continuous flow based on demand, eliminating waste, increasing throughput and turnaround time, improving communication and visibility, and establishing a culture of continuous improvement.