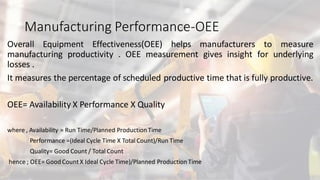

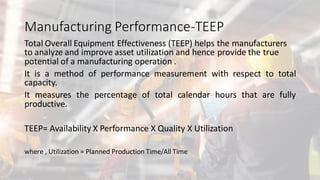

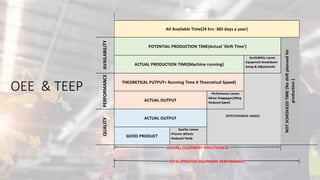

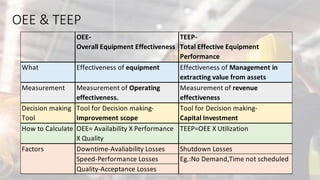

OEE and TEEP are metrics used to measure manufacturing performance and effectiveness. OEE measures the percentage of planned production time that is fully productive by considering availability, performance, and quality. TEEP expands on OEE by also considering utilization, measuring the percentage of total calendar hours that are fully productive. Both tools can be used to identify improvement opportunities and make decisions around capital investments by analyzing factors that cause losses like downtime, speed, and quality issues.