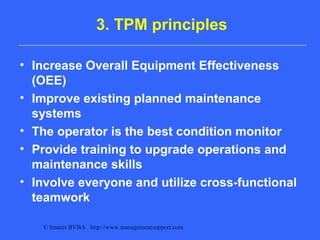

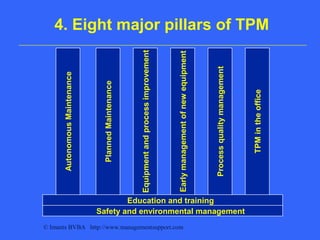

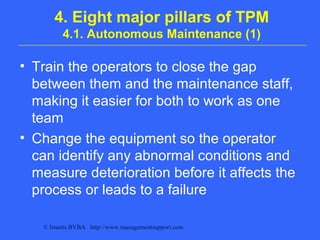

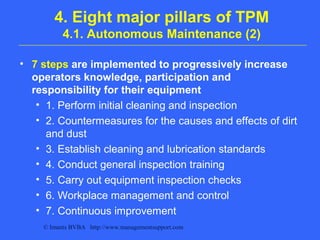

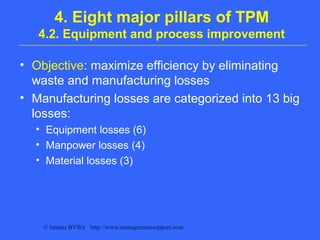

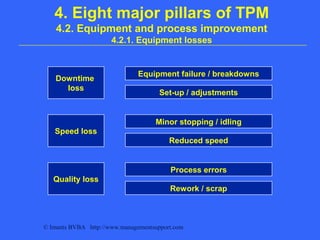

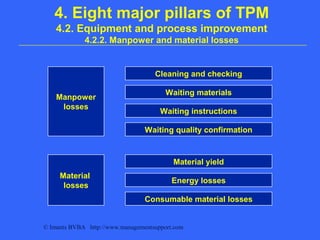

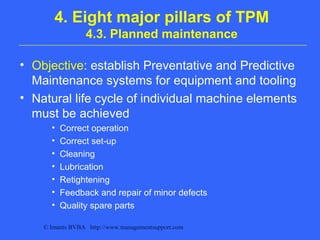

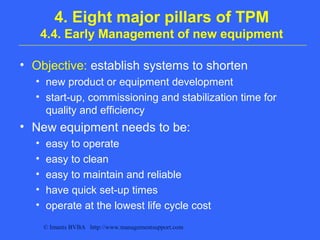

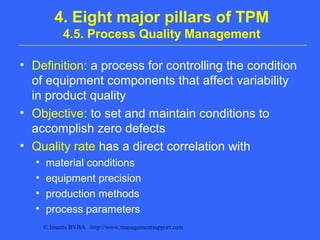

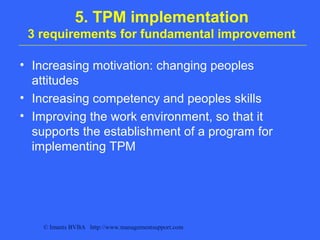

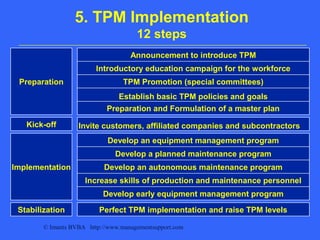

This document provides an overview of Total Productive Maintenance (TPM). It defines TPM, describes its origins in quality management techniques, and outlines its eight pillars including autonomous maintenance, planned maintenance, and equipment improvement. The document explains how to implement a TPM program over multiple steps, from establishing goals to training personnel. It concludes by noting the benefits of TPM such as increased equipment productivity and reduced costs.