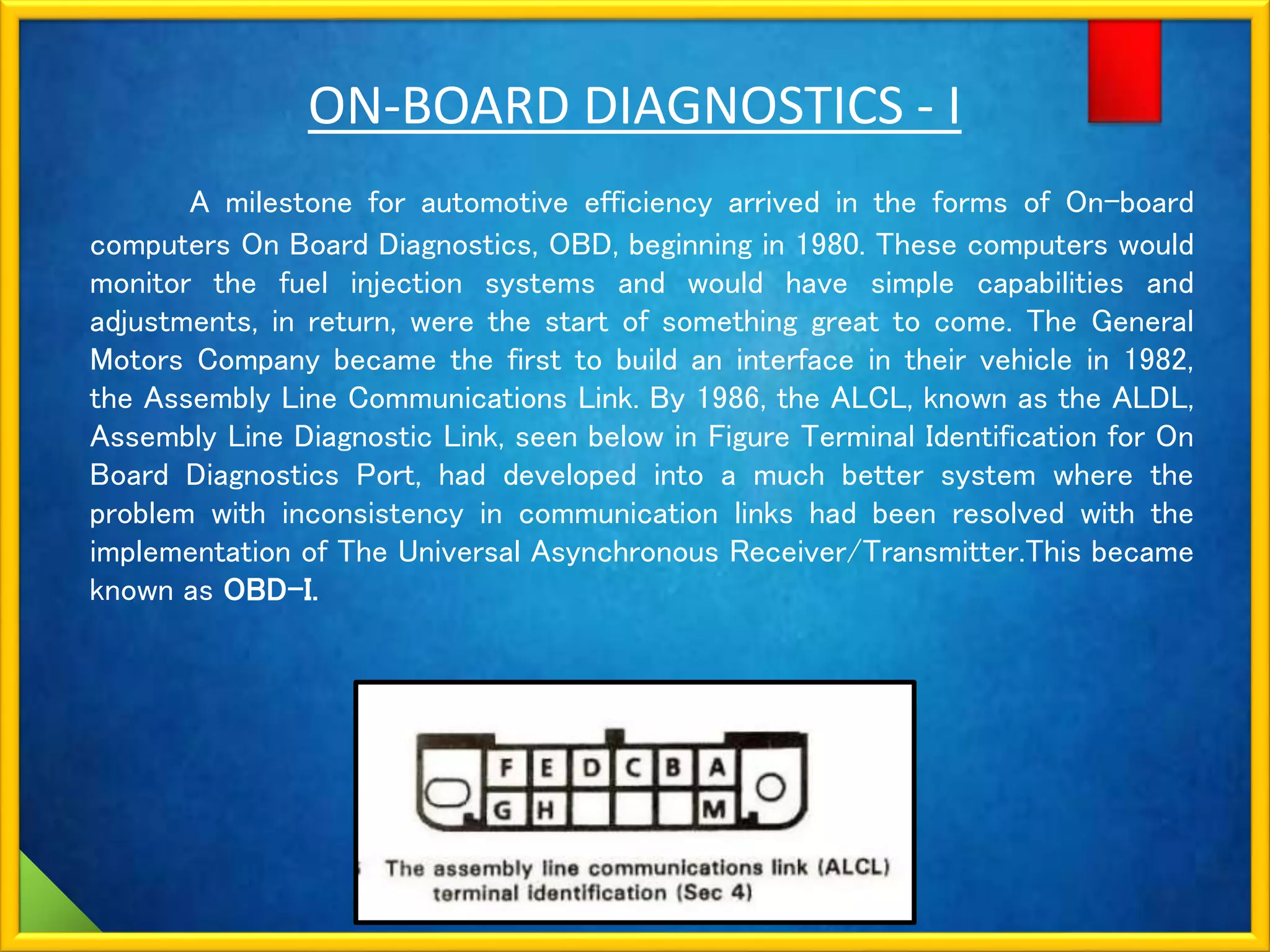

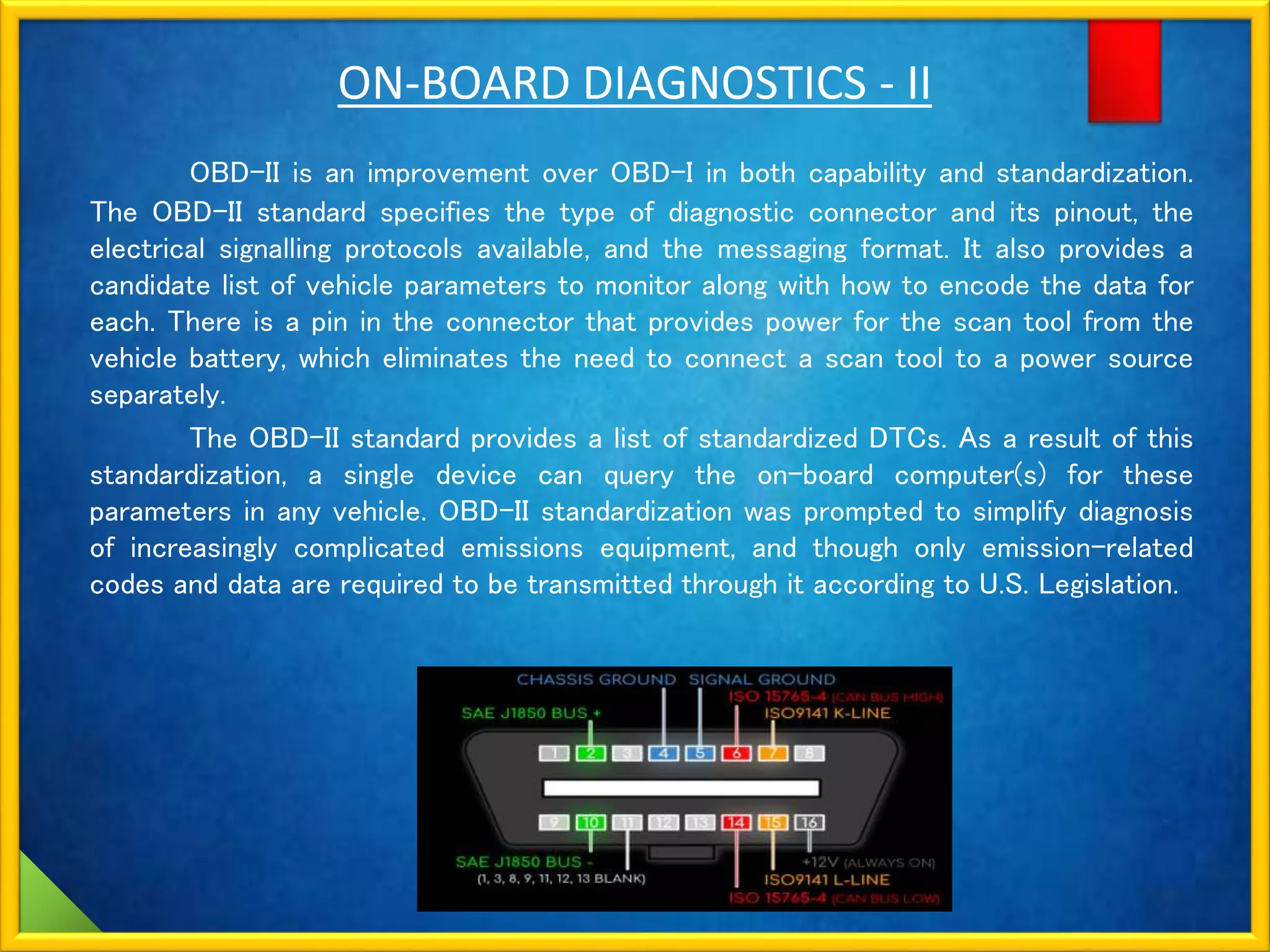

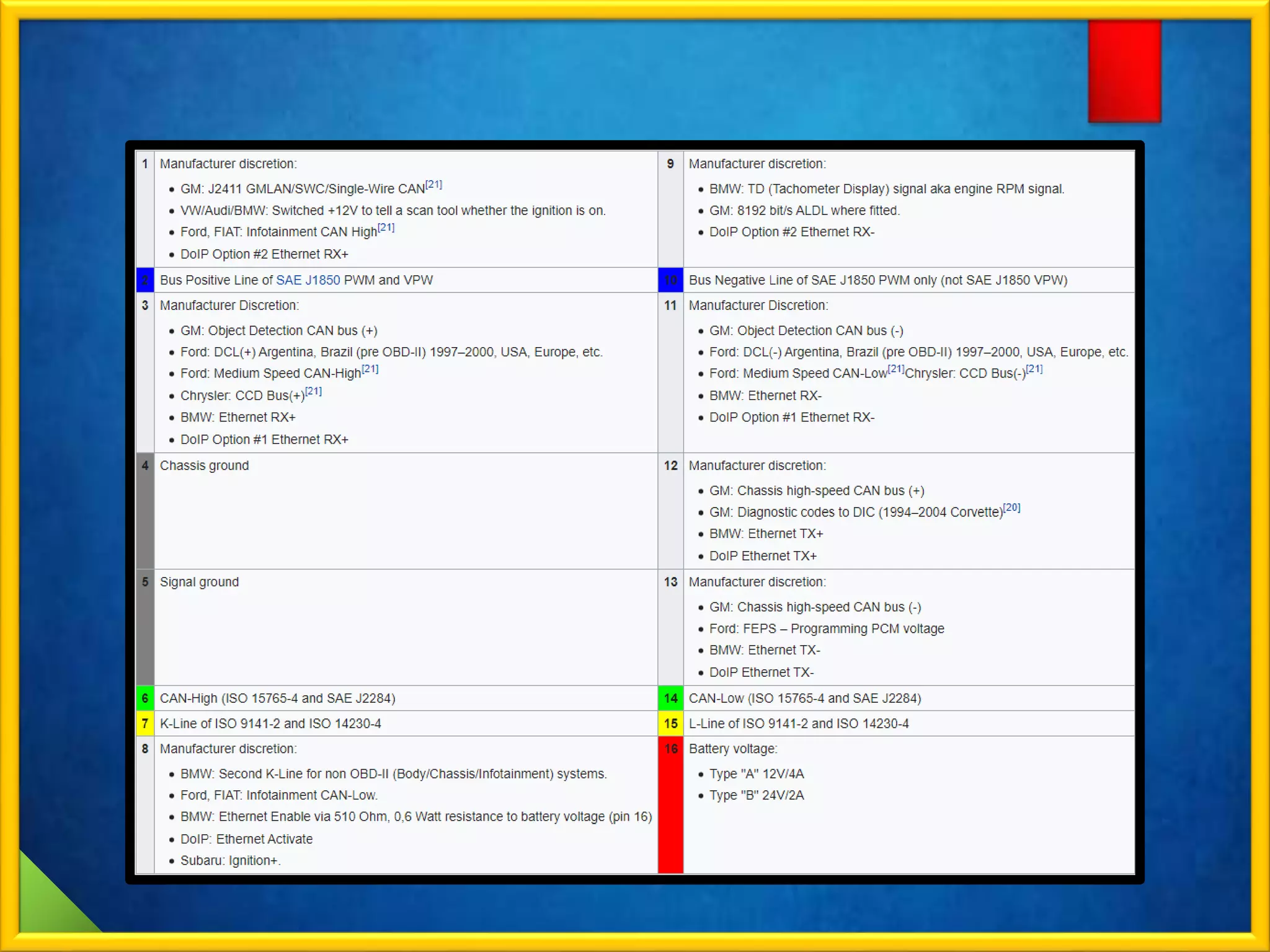

The document discusses the history and development of on-board vehicle diagnostics (OBD) from the early OBD-I systems introduced in 1980 up to the current OBD-II standard. It describes how OBD has evolved from simple fuel injection monitoring on early systems to a standardized diagnostic protocol (OBD-II) that provides access to diagnostic data for various vehicle subsystems. The OBD-II standard specifies aspects like the connector, communication protocols, trouble codes, and has expanded the use of diagnostic data beyond emissions monitoring alone. While offering benefits, security research has also shown vulnerabilities in how OBD systems have been implemented.