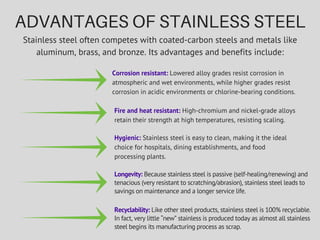

Stainless steel is a low-carbon steel with at least 10.5% chromium, providing corrosion resistance and strength. Its versatility allows for various applications in architecture, automotive, medical fields, and culinary tools, and it remains durable and hygienic. With a history dating back to early corrosion-resistant metals, stainless steel has evolved into a widely used recyclable material with a multitude of grades and finishes.