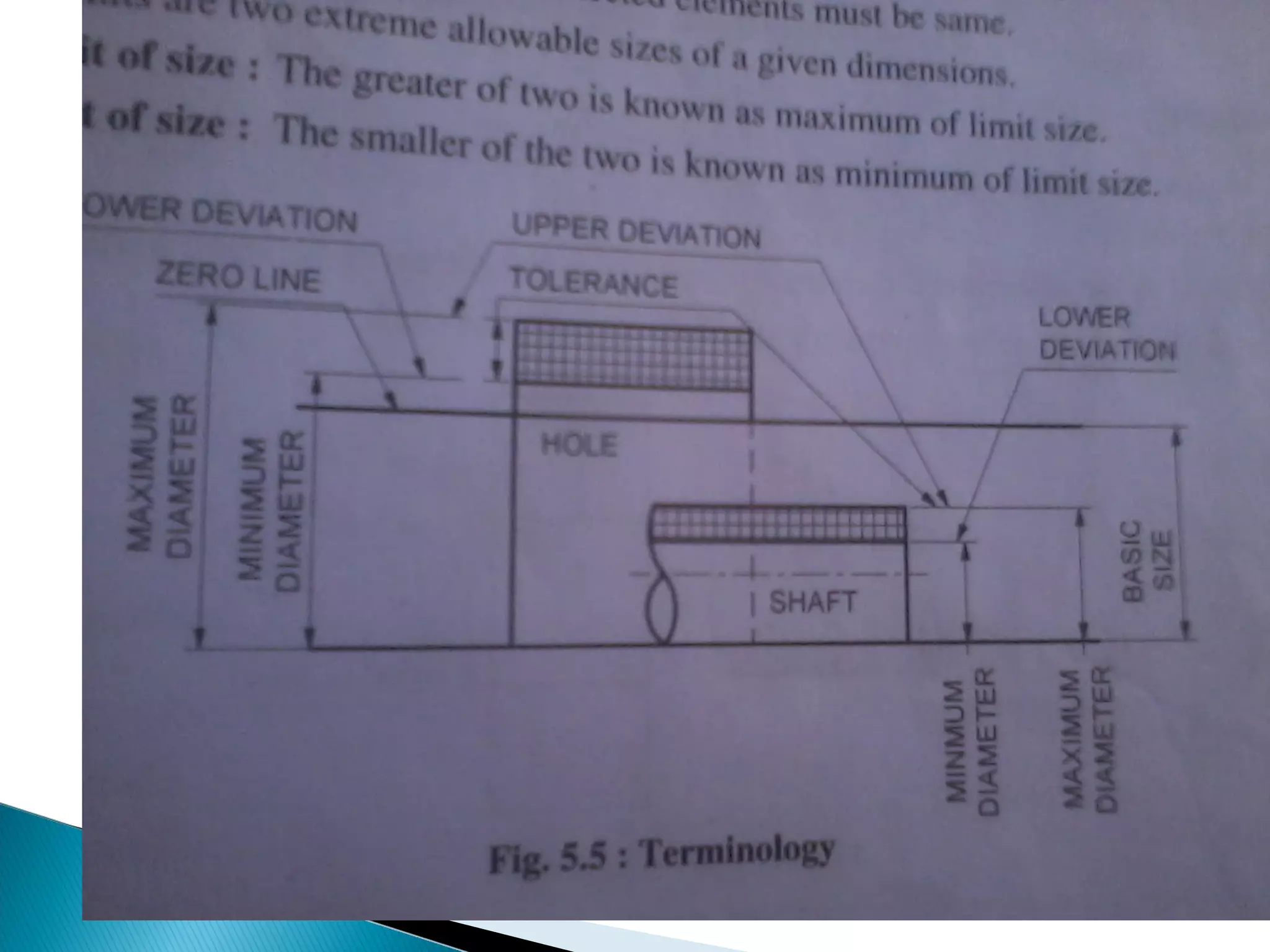

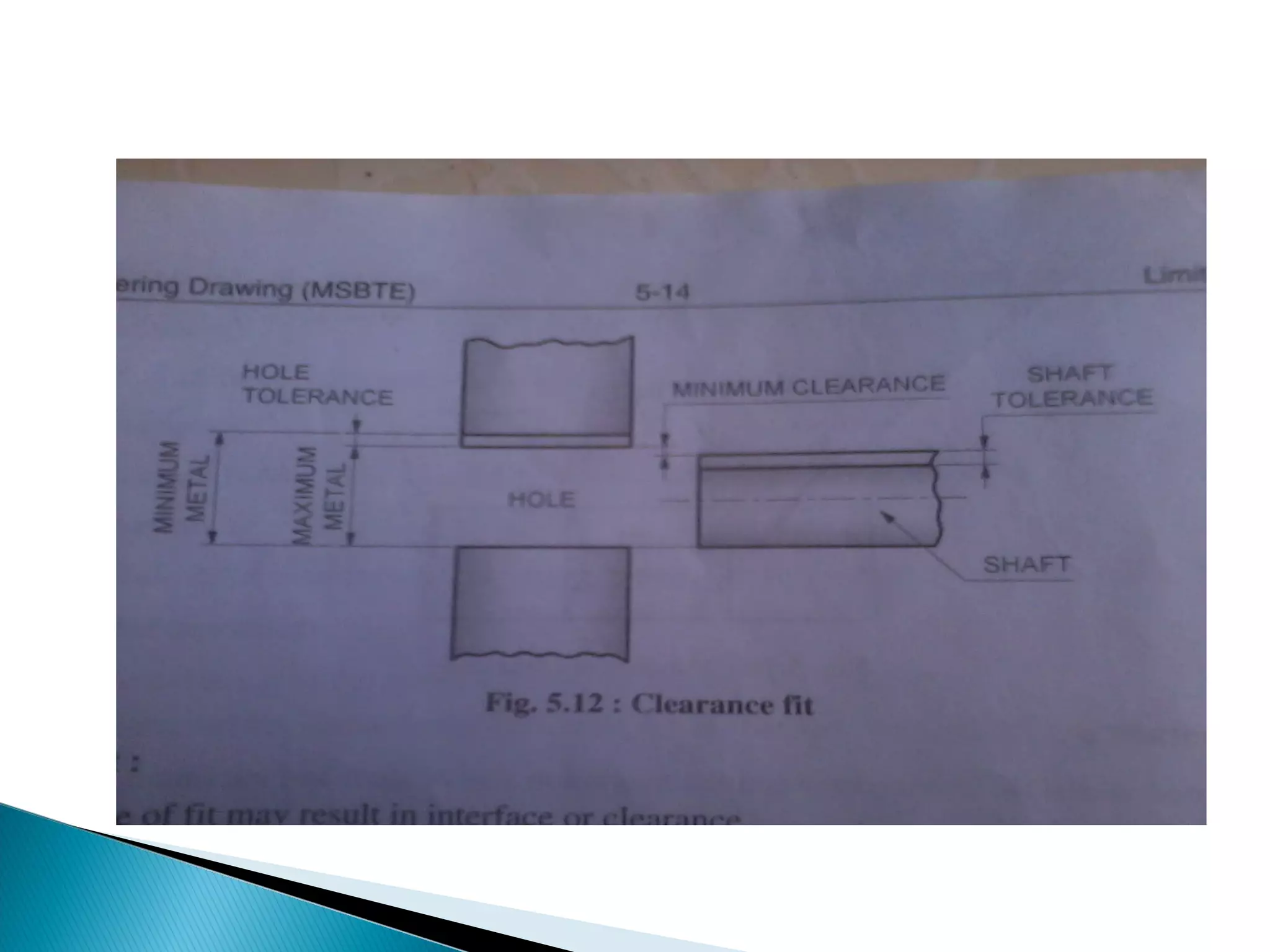

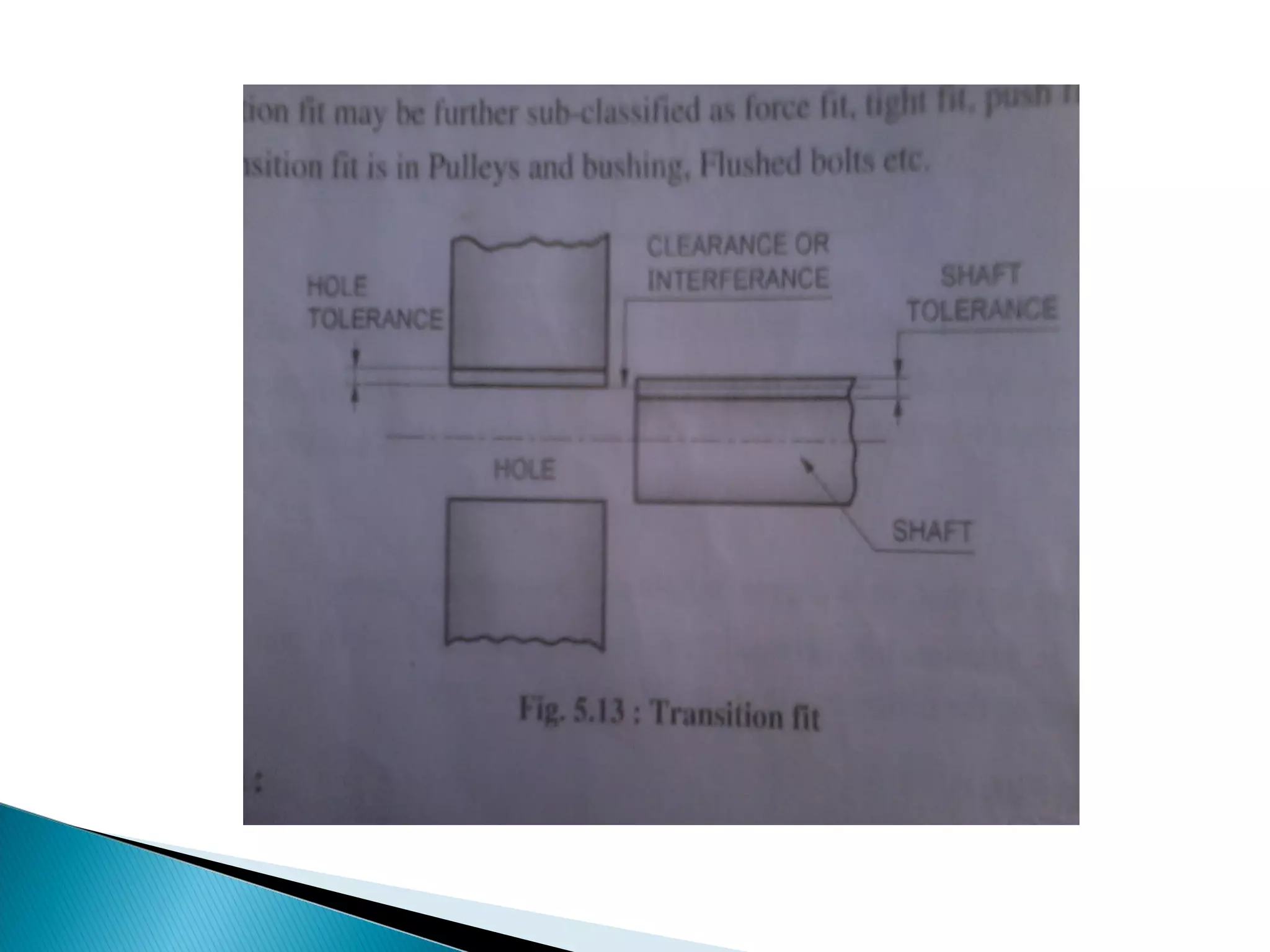

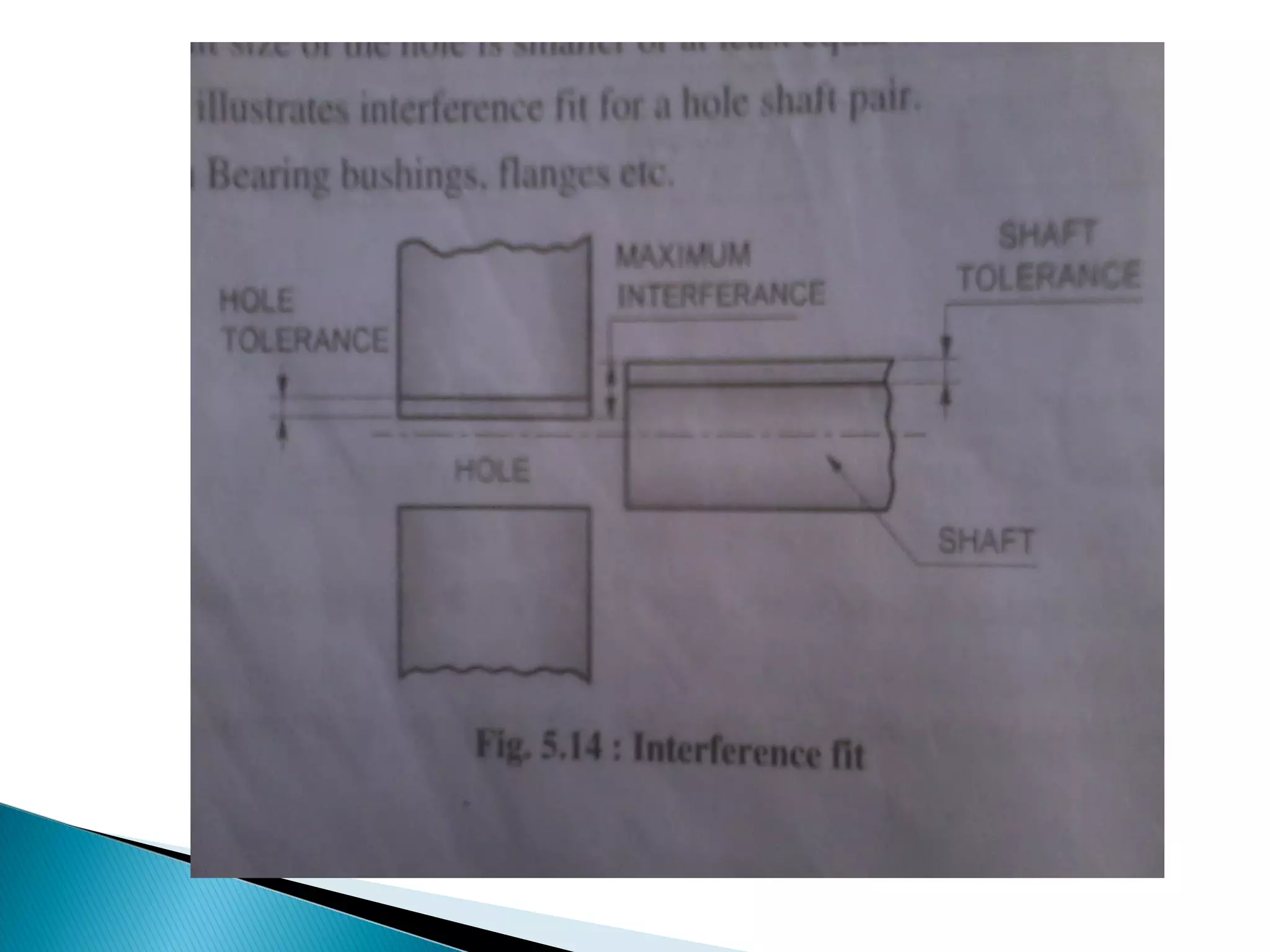

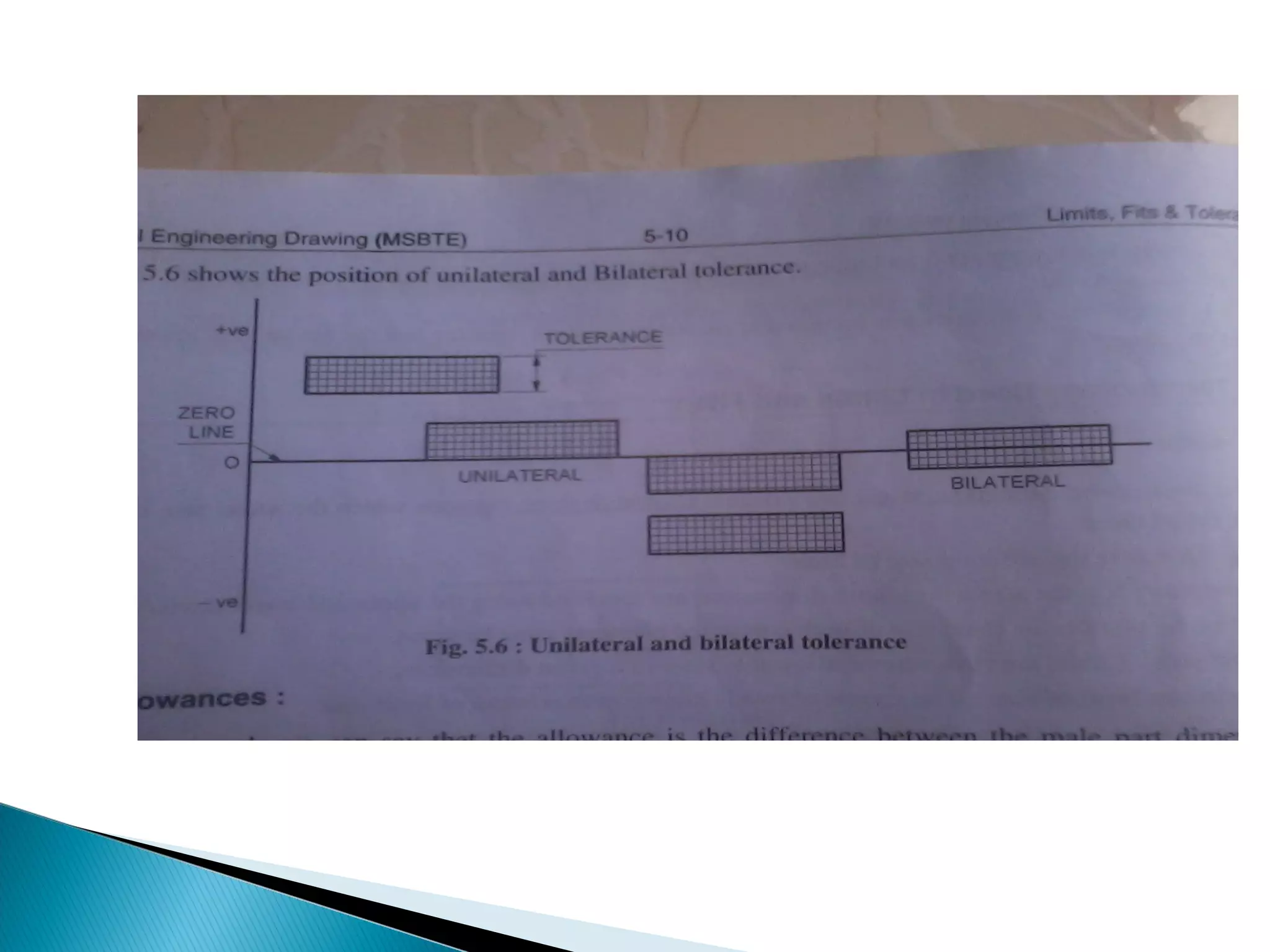

This document defines limits, fits, and tolerances for mechanical parts. It defines limits as the maximum and minimum allowable sizes between which the actual size must fall. It describes three common fits - clearance fit, interference fit, and transition fit. Clearance fit always has a gap between parts, interference fit causes overlapping, and transition fit allows for both clearance and interference. Tolerances are defined as the total permissible variation between the maximum and minimum limits, which can be either unilateral with variation in one direction, or bilateral with variation in both directions.